Hi all.

I have a friend that bought a -9a from the builder at 40.1 hours. I am a CFI working with him on instrument stuff the -9a and he tells me he uses 80kts for flap speed. Looking at his POH it states "87kts maximum full flaps speed" and the owner is just using 80 to have some margin (a hint to his conservative flying style). Yes his GRT glass and backup steam gauges are both in kts. He is having trouble getting slowed down on instrument approaches. He can manage if he starts to slow about 3-4 miles before starting down the hill and just flies the entire procedure below flap speed but once starting downhill he is not yet comfortable with the maneuvers needed to slow to flap speeds while on a glideslope.

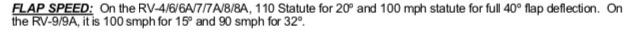

I have been scouring the net to see if there is an intermediate speed for a partial flap setting such as something like 0°-10° maximum 110kts then 10°-20° 100kts before just getting to a full flap speed of 87kts. I find the RV-7 has something along these lines of a graduated flap speeds but it is a different wing than the -9. This is a straight forward, no mods -9a build.

Is there any kind of a partial flap speed setting that has been found/calculated/tested by others that we could consider or is the -9a really just the single speed setting for all flap positions? I understand that each is experimental and has its own limitations but at the same time they should all be pretty similar in their limitations.

Thanks guys

Shaun

I have a friend that bought a -9a from the builder at 40.1 hours. I am a CFI working with him on instrument stuff the -9a and he tells me he uses 80kts for flap speed. Looking at his POH it states "87kts maximum full flaps speed" and the owner is just using 80 to have some margin (a hint to his conservative flying style). Yes his GRT glass and backup steam gauges are both in kts. He is having trouble getting slowed down on instrument approaches. He can manage if he starts to slow about 3-4 miles before starting down the hill and just flies the entire procedure below flap speed but once starting downhill he is not yet comfortable with the maneuvers needed to slow to flap speeds while on a glideslope.

I have been scouring the net to see if there is an intermediate speed for a partial flap setting such as something like 0°-10° maximum 110kts then 10°-20° 100kts before just getting to a full flap speed of 87kts. I find the RV-7 has something along these lines of a graduated flap speeds but it is a different wing than the -9. This is a straight forward, no mods -9a build.

Is there any kind of a partial flap speed setting that has been found/calculated/tested by others that we could consider or is the -9a really just the single speed setting for all flap positions? I understand that each is experimental and has its own limitations but at the same time they should all be pretty similar in their limitations.

Thanks guys

Shaun