I am installing a TruTrak roll servo per their RV6 fuselage installation plan except I really don't like the reinforcement plate messing up the nice and smooth under side of my fuselage. I know it is the bottom and only visible when looking under, but I prefer leaving the exterior of my plane clean and undisturbed if possible.

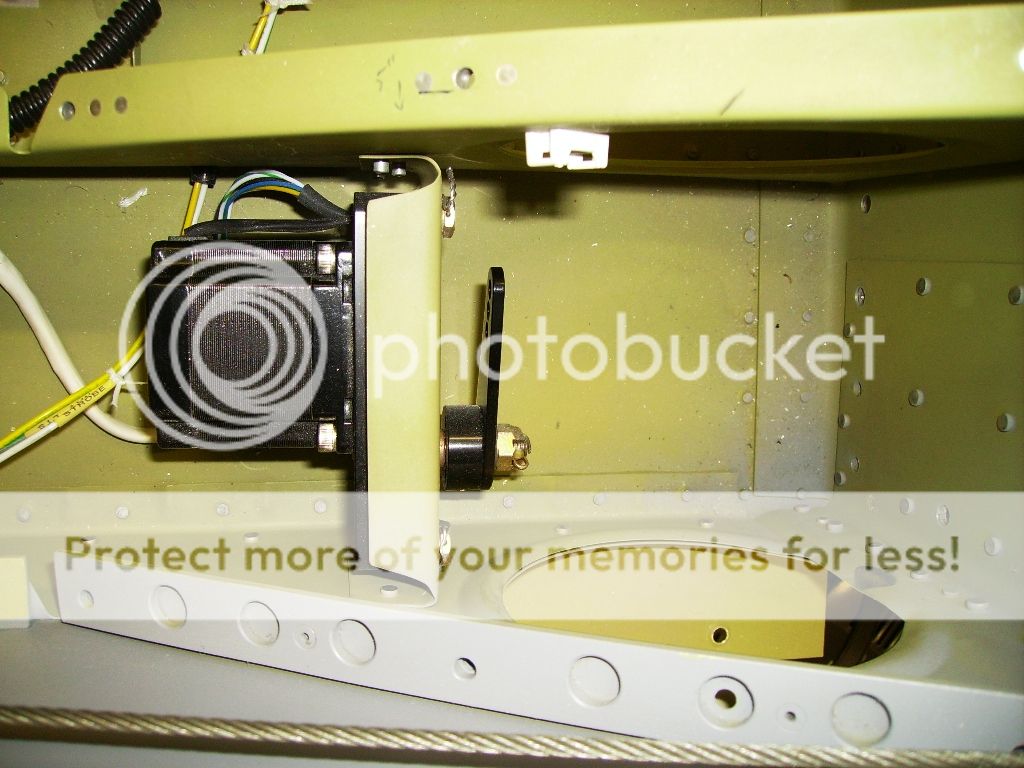

I see the Dynon servo installation instruction mentioned fixing the servo mount to seat ribs instead of the bottom skin, but offered no plan or other details. Does anyone have a picture or two to show how this is done?

I am also considering installing per TruTrak plan without the plate but with more screws to distribute the load. Do you see any problem with this?

Any feedback or comments are appreciated.

I see the Dynon servo installation instruction mentioned fixing the servo mount to seat ribs instead of the bottom skin, but offered no plan or other details. Does anyone have a picture or two to show how this is done?

I am also considering installing per TruTrak plan without the plate but with more screws to distribute the load. Do you see any problem with this?

Any feedback or comments are appreciated.