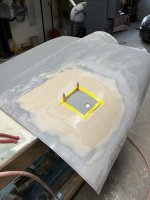

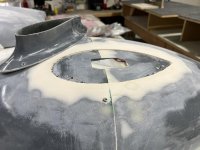

Love that spinner!

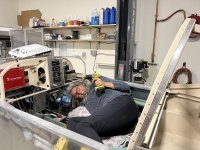

Hung my Thunderbolt IO-390 EXP119 a few months ago. This weekend i mounted the Prop. I'll get more shots after I screw on spinner and remove the plastic - this is just a teaser. Thanks to Jeff and team at TB for beautiful engine.