Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lightspeed GM coils

- Thread starter mckes

- Start date

kaweeka

Well Known Member

LSE Plasma III coil failure

I had a coil failure of my Plasma III ignition last weekend returning from San Diego. My aircraft has 719 hours and this is the first problem with my Lightspeed ignition. I measured the resistance of the output coils and indeed the one for cylinder 3,4 lower plugs was well out of spec (7.5kOhms spec and 1.3MegaOhms measured). I called Klaus and he send 4 new coils at my request. The new coils are completely different in form and appear to be 0.5 Ohm dual output coils from Dynatek. They make high output ignition systems for motorcycles and ATVs. I needed to make new mounting brackets which was not a problem. Luckily, the existing wires fit. What I didn't expect was the positive lead on the bad coil had broken. Klaus uses coax cable and the positive lead is a solid copper wire. I'm not sure if vibration broke the solid wire and if that fried the coil. I'm not an engineer! Additional new tidbit while speaking with Klaus was the difference in spark plug gap with the new coils. Higher output and duration of the spark he says needs a larger gap at .040". My back went out today while I was working on this so I'll update when I can move.

I had a coil failure of my Plasma III ignition last weekend returning from San Diego. My aircraft has 719 hours and this is the first problem with my Lightspeed ignition. I measured the resistance of the output coils and indeed the one for cylinder 3,4 lower plugs was well out of spec (7.5kOhms spec and 1.3MegaOhms measured). I called Klaus and he send 4 new coils at my request. The new coils are completely different in form and appear to be 0.5 Ohm dual output coils from Dynatek. They make high output ignition systems for motorcycles and ATVs. I needed to make new mounting brackets which was not a problem. Luckily, the existing wires fit. What I didn't expect was the positive lead on the bad coil had broken. Klaus uses coax cable and the positive lead is a solid copper wire. I'm not sure if vibration broke the solid wire and if that fried the coil. I'm not an engineer! Additional new tidbit while speaking with Klaus was the difference in spark plug gap with the new coils. Higher output and duration of the spark he says needs a larger gap at .040". My back went out today while I was working on this so I'll update when I can move.

A common point of failure in the LSE system is at the primary wire terminations -- ie. the Fast-On terminations AND RG-400 coax.

While risking the wrath of some and voiding the warranty, etc. etc., some of us are using good old fashioned MIL-C-27500, 2 conductor+shield 20GA wire with TE PIDG Fast-On crimps and BNC connectors for the primary connections.

Also, coils are available from Nology -- https://www.nology.com/profireauto.html, part 152 001 070 PFC-06D

While risking the wrath of some and voiding the warranty, etc. etc., some of us are using good old fashioned MIL-C-27500, 2 conductor+shield 20GA wire with TE PIDG Fast-On crimps and BNC connectors for the primary connections.

Also, coils are available from Nology -- https://www.nology.com/profireauto.html, part 152 001 070 PFC-06D

Last edited:

...

Also, coils are available from Nology -- https://www.nology.com/profireauto.html, part 152 001 070 PFC-06D

THANK YOU, THANK YOU for posting that info!!

kaweeka

Well Known Member

The difference in cost isn't that much and, IMHO, it's worth supporting the companies and folks who support our planes, are there even on Sunday to answer our questions and offer assistance when we need it most. I was only mentioning the equivalent product to call out the motorcycle application would seem to mean a more robust construction. Again, I'm not an engineer and only reasoning that. Take all that for what it's worth --- probably not much

Best,

David

Best,

David

The difference in cost isn't that much and, IMHO, it's worth supporting the companies and folks who support our planes, are there even on Sunday to answer our questions and offer assistance when we need it most. I was only mentioning the equivalent product to call out the motorcycle application would seem to mean a more robust construction. Again, I'm not an engineer and only reasoning that. Take all that for what it's worth --- probably not much

Best,

David

Totally agree, but it is a good idea to have a backup.

Solder Sleeves

I have had luck with PIDG connectors for both the core and the shield of the RG-400. I used a solder sleeve onto the shield braid instead of the "strip it back and twist it" method. The solder sleeve has a pigtail that I then crimped the PIDG onto. The center core was backed up with heat shrink and the coax supported close to the coil. So far so good.

A common point of failure in the LSE system is at the primary wire terminations -- ie. the Fast-On terminations AND RG-400 coax.

While risking the wrath of some and voiding the warranty, etc. etc., some of us are using good old fashioned MIL-C-27500, 2 conductor+shield 20GA wire with TE PIDG Fast-On crimps and BNC connectors for the primary connections.

I have had luck with PIDG connectors for both the core and the shield of the RG-400. I used a solder sleeve onto the shield braid instead of the "strip it back and twist it" method. The solder sleeve has a pigtail that I then crimped the PIDG onto. The center core was backed up with heat shrink and the coax supported close to the coil. So far so good.

The solder sleeve has a pigtail that I then crimped the PIDG onto.

That's a good idea.

I've got over 100 hours on the new, larger coils, now and they seem to be working well. Yes, the form factor is different, but making a new bracket isn't that hard. They are larger, and hopefully more robust.

Vic

Vic

Hi Vic, which style coils are you using? For those wondering about the standard lightspeed triumph coils I believe Klaus is the cheapest so you’re best off going through him. I’m just trying to find out what the larger/heavy duty coils actually are before getting replacements and wether people have had success as there’s no real info on them. I have just heard people referring to them as GM coils.

Cheers,

Sam

Cheers,

Sam

Hi Vic, which style coils are you using? For those wondering about the standard lightspeed triumph coils I believe Klaus is the cheapest so you’re best off going through him. I’m just trying to find out what the larger/heavy duty coils actually are before getting replacements and wether people have had success as there’s no real info on them. I have just heard people referring to them as GM coils.

Cheers,

Sam

They are the new coils provided by Klaus.

Vic

A buddy did some research on replacement coils for his original LSE Plasma III coils (in talking with Klaus) and came up with this Nology P/N: 152 051 350, PFC-30D, for 3.0 Ohm Systems (Electronic Ignition - 2.4 Ohm Actual). Don't know if Klaus agreed or not.

Would both choices work with the Plasma III?

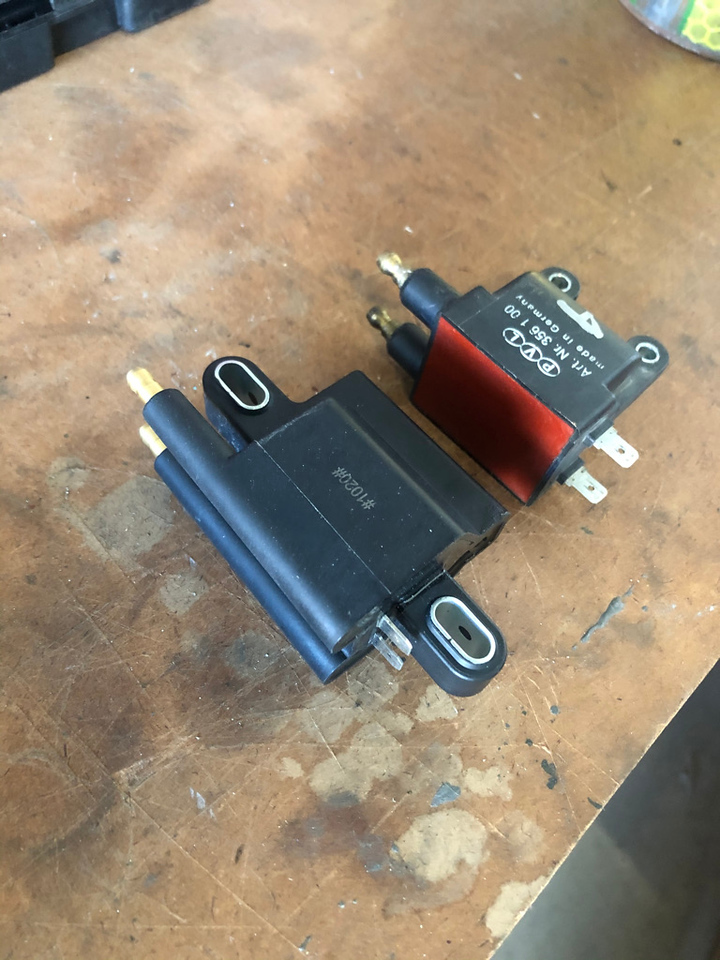

View attachment 8945

Per the LSE manual, the input resistance should be ~ 1 Ohm, the coils listed don't meet that specification.

deek

Well Known Member

I have had luck with PIDG connectors for both the core and the shield of the RG-400. I used a solder sleeve onto the shield braid instead of the "strip it back and twist it" method. The solder sleeve has a pigtail that I then crimped the PIDG onto. The center core was backed up with heat shrink and the coax supported close to the coil. So far so good.

^^^ Excellent!^^^ Good installation practices and securing the RG-400 (not solid core as Klaus initially provided decades ago) to prevent vibration and relative motion is key to reliability. I have almost 6,000 hours aggregate on five LSE systems with no coax/connector failures; one coil failure. I might own the coil failure; the coils are mounted to crankcase upper spine which is on the hot side of updraft EZ's

I had a coil failure of my Plasma III ignition last weekend returning from San Diego. My aircraft has 719 hours and this is the first problem with my Lightspeed ignition. I measured the resistance of the output coils and indeed the one for cylinder 3,4 lower plugs was well out of spec (7.5kOhms spec and 1.3MegaOhms measured). I called Klaus and he send 4 new coils at my request. The new coils are completely different in form and appear to be 0.5 Ohm dual output coils from Dynatek. They make high output ignition systems for motorcycles and ATVs. I needed to make new mounting brackets which was not a problem. Luckily, the existing wires fit. What I didn't expect was the positive lead on the bad coil had broken. Klaus uses coax cable and the positive lead is a solid copper wire. I'm not sure if vibration broke the solid wire and if that fried the coil. I'm not an engineer! Additional new tidbit while speaking with Klaus was the difference in spark plug gap with the new coils. Higher output and duration of the spark he says needs a larger gap at .040". My back went out today while I was working on this so I'll update when I can move.

kaweeka do you have a picture of how you mounted these new coils and the brackets you made?

I just upgraded my system and was surprised to see a new style coil, my old setup had the coils mounted to the top of the case.

Thanks

kaweeka

Well Known Member

kaweeka do you have a picture of how you mounted these new coils and the brackets you made?

I just upgraded my system and was surprised to see a new style coil, my old setup had the coils mounted to the top of the case.

Thanks

I would be happy to if someone would refresh me on how to post a picture.

kaweeka

Well Known Member

Hopefully this picture uploaded. As the coils are a bit larger, the ones on the firewall extend down slightly further than previous. I'm not sure how that will affect removing the oil filter. Luckily, the existing wires fit the new installation. I replaced the NGK with the Denso as Klaus suggested and gapped to .040". Started up very quickly and ran smoothly.

Last edited:

GM coils.

Duff

I have a set I got from Klaus sometime back but never used them. If you get me an email address I’ll send you some pics.Hi Vic, which style coils are you using? For those wondering about the standard lightspeed triumph coils I believe Klaus is the cheapest so you’re best off going through him. I’m just trying to find out what the larger/heavy duty coils actually are before getting replacements and wether people have had success as there’s no real info on them. I have just heard people referring to them as GM coils.

Cheers,

Sam

Duff

I cannot see what the actual mag drop is on my 540 when doing a run up on my GRT display. I do know its rougher that my standard Slick mag. I did a simple in flight mag check and it is indeed rougher than my mag. I have new plugs in it and normal EGT's just curious what others experience. I have the older lightspeed with original coils and new wires

kaweeka

Well Known Member

Update on the new coils. I haven't flown much this year and only have about 24 hours on the new coils. This weekend, one failed. I've emailed Klaus and we'll see what happens. Not thrilled about it. I understand about vibration and tried to limit as much as possible. Any information I get I'll pass along.

Jon Clements

Well Known Member

Hi Kaweeka

Did you sort this issue out. I have just had my LSE second coil failure on my LSE Plasma III system and I am looking to install Dynatek Dual Output Coils 0.5ohm - are you still using them and what Plug / gap are you using?

Cheers Jon

Did you sort this issue out. I have just had my LSE second coil failure on my LSE Plasma III system and I am looking to install Dynatek Dual Output Coils 0.5ohm - are you still using them and what Plug / gap are you using?

Cheers Jon

kaweeka

Well Known Member

I did get through it. Indeed, there was a bad coil. Klaus got it replaced since it was only a few months old. I also spoke to the folks at Dynatec. Very nice folks. Klaus was actually extremely helpful with his advice and generous with his time. He recommends a gap of 0.040". That seem large but he says thats what it should be. I will yield to his knowledge\

Full Throttle

Active Member

The wider gap on the plugs makes the coils work harder. I would gap a new plugs at .025 and I don't think it will affect your overall performance.