tkatc

Well Known Member

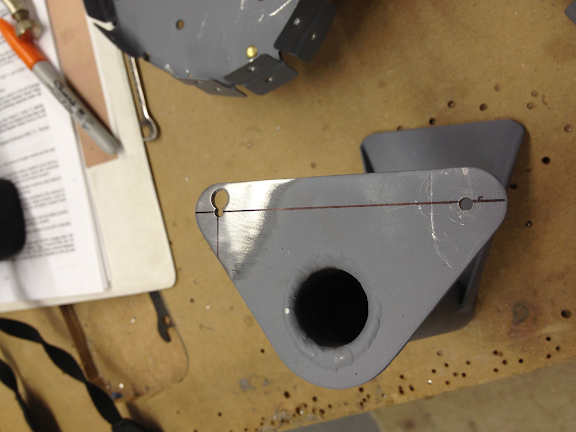

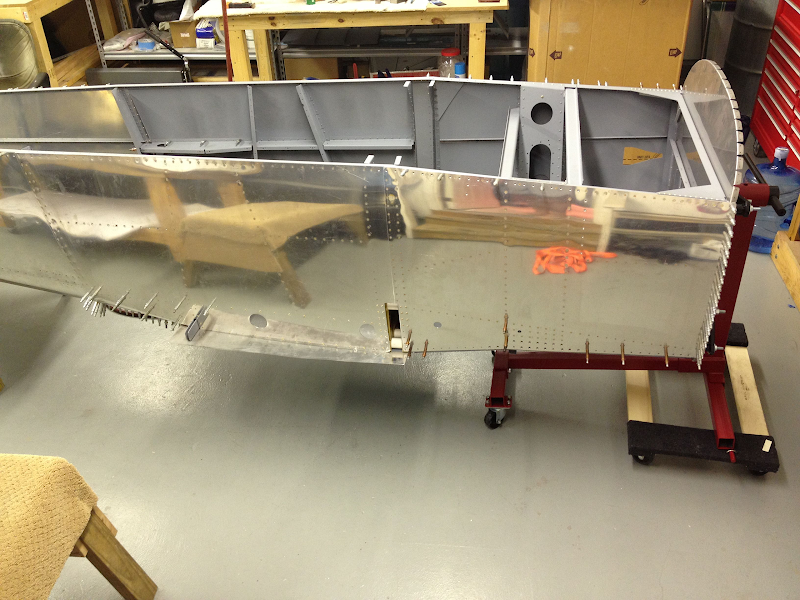

Seatbelt attach points. Lower and middle longerons...

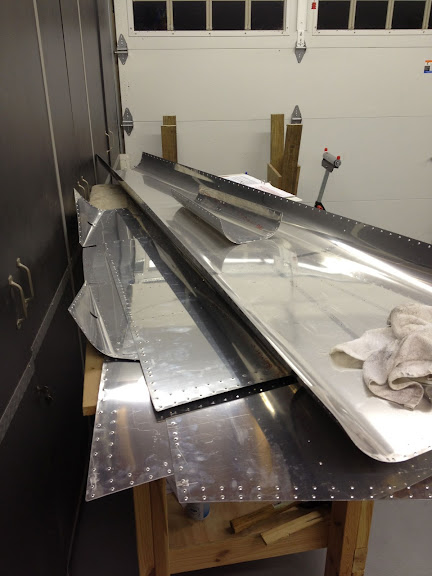

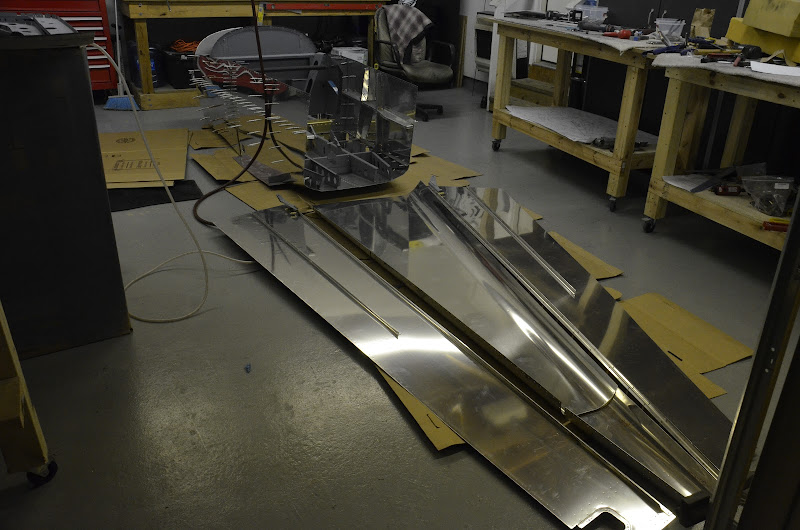

Laying out the side and lower skins. The garage is getting smaller!!

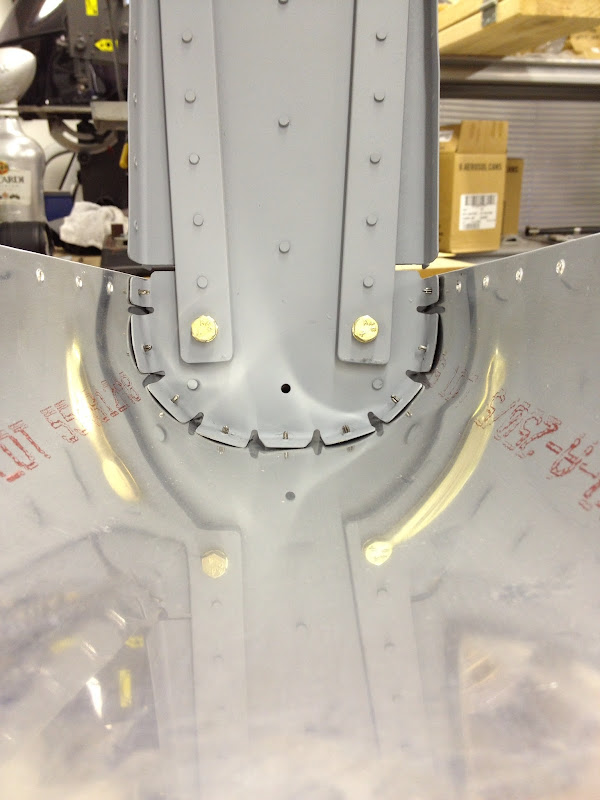

Added side skins and bulkheads.

Adding the bottom skin is proving difficult for me. Lining everything up is a challenge.

I worked the bottom skin into it's general postion and I am getting more and more clecoes in place but it is a struggle. This skin is placed between the forward bottom skin and the 807 bulkhead as well as mid side skins. Everything is very tight.

This is where I am currently and I ran out of clecoes. I borrowed more clecoes from the PTW boys and I purchased some others so I am able to continue on. Thanks again David and Mark!!!

Not sure how much I will get done in the near future because I have to rebuild the rudder on my -7A. I suppose I will put together the final order for the finish kit this week before the price increase.

Laying out the side and lower skins. The garage is getting smaller!!

Added side skins and bulkheads.

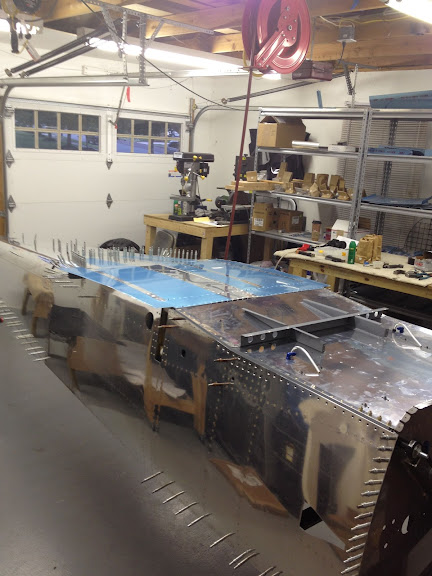

Adding the bottom skin is proving difficult for me. Lining everything up is a challenge.

I worked the bottom skin into it's general postion and I am getting more and more clecoes in place but it is a struggle. This skin is placed between the forward bottom skin and the 807 bulkhead as well as mid side skins. Everything is very tight.

This is where I am currently and I ran out of clecoes. I borrowed more clecoes from the PTW boys and I purchased some others so I am able to continue on. Thanks again David and Mark!!!

Not sure how much I will get done in the near future because I have to rebuild the rudder on my -7A. I suppose I will put together the final order for the finish kit this week before the price increase.