Thanks Kurt, hopefully the Wx will cooperate!

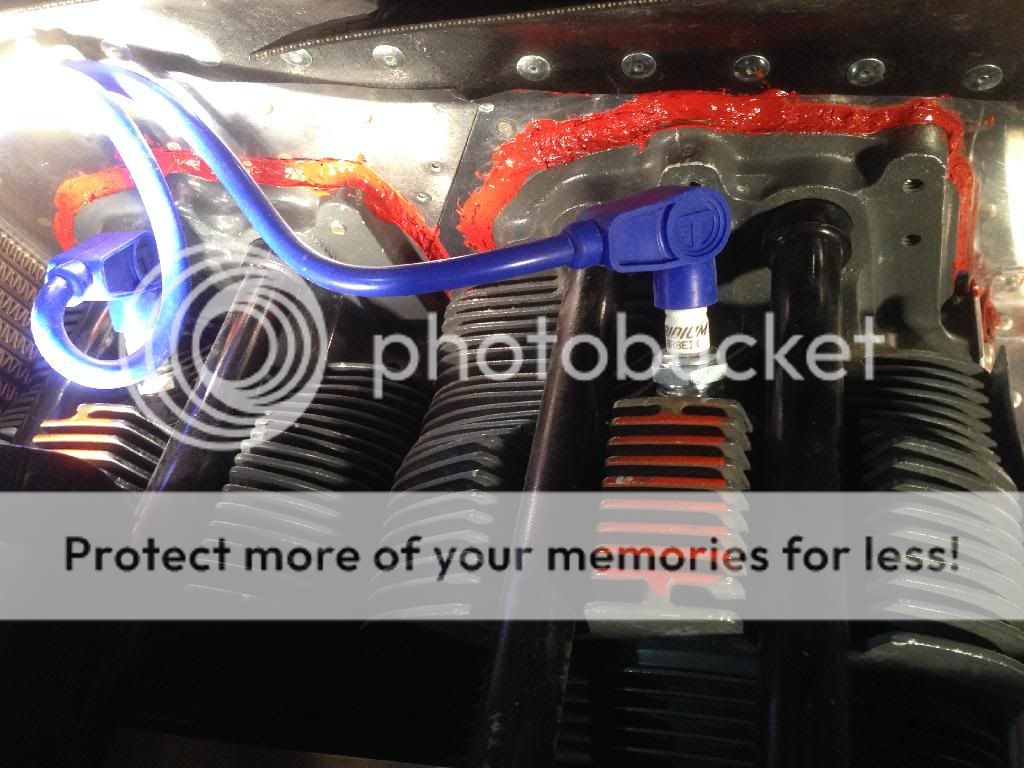

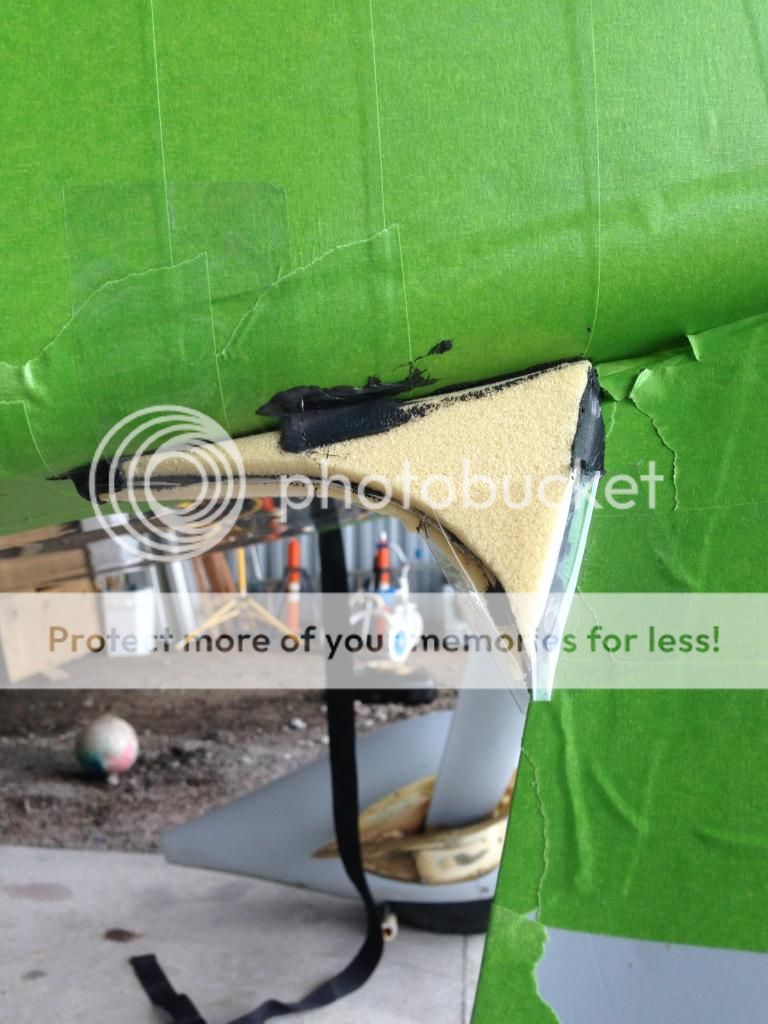

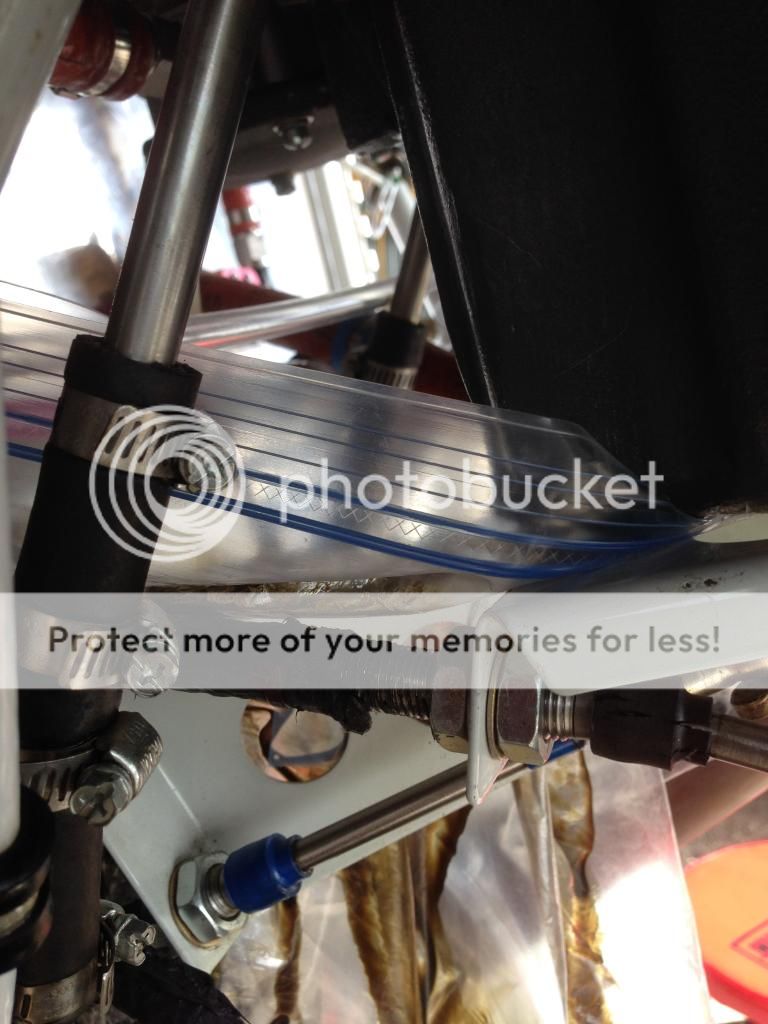

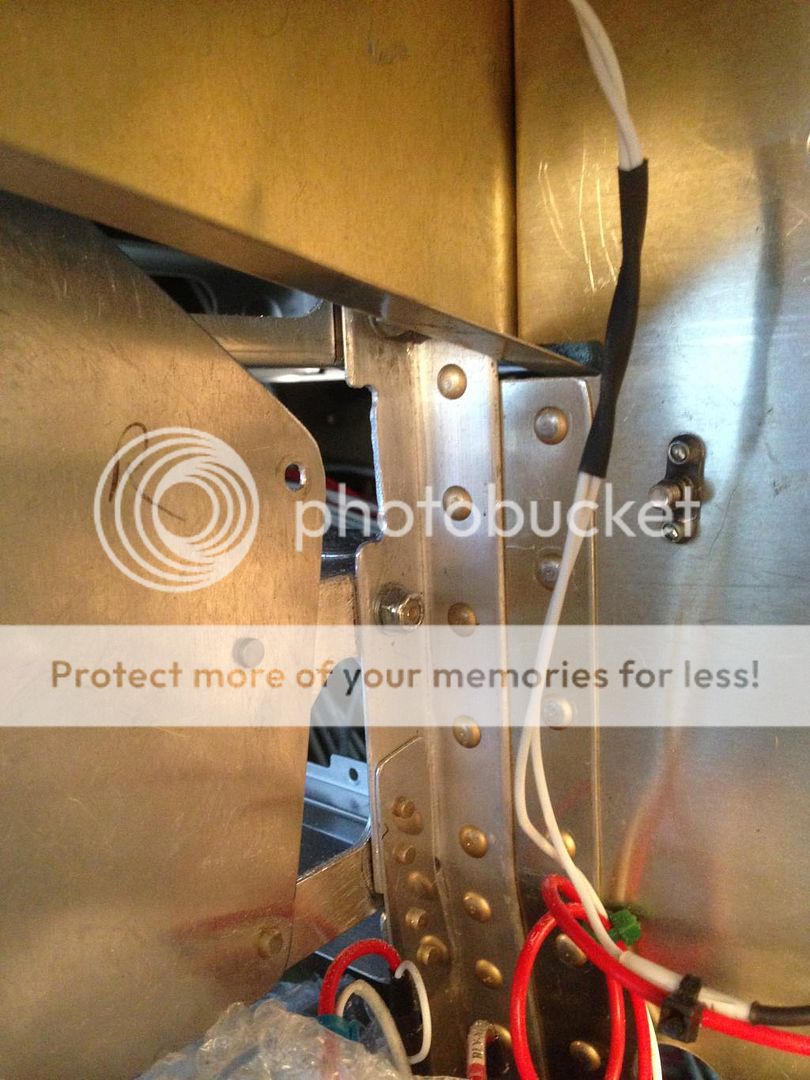

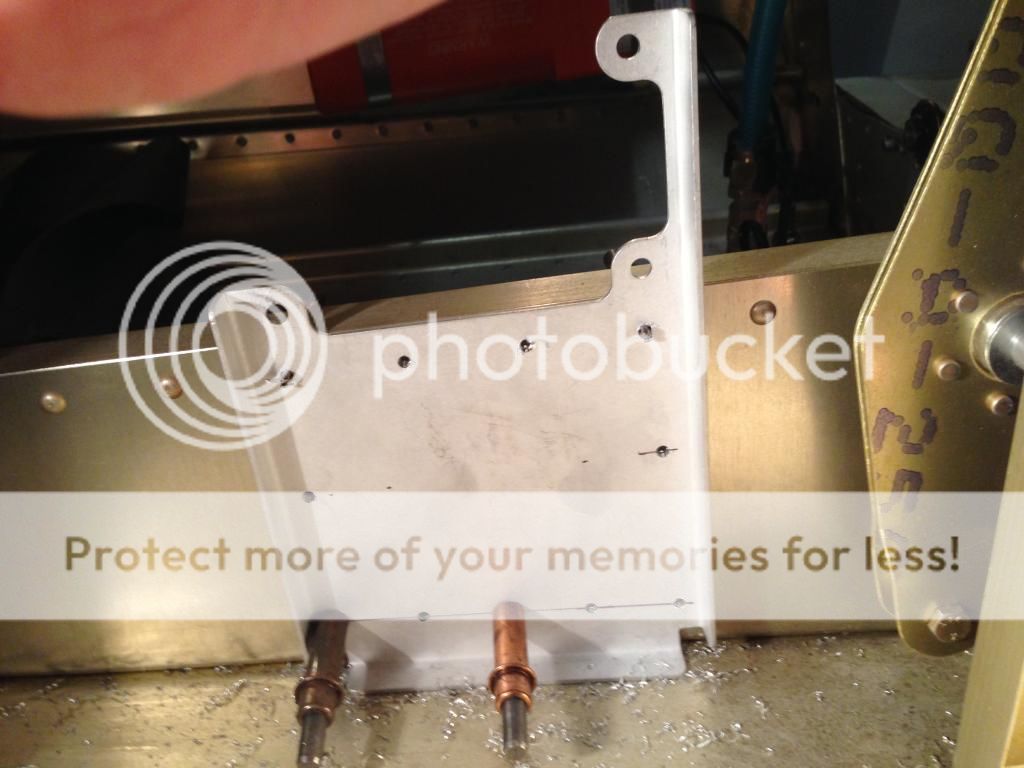

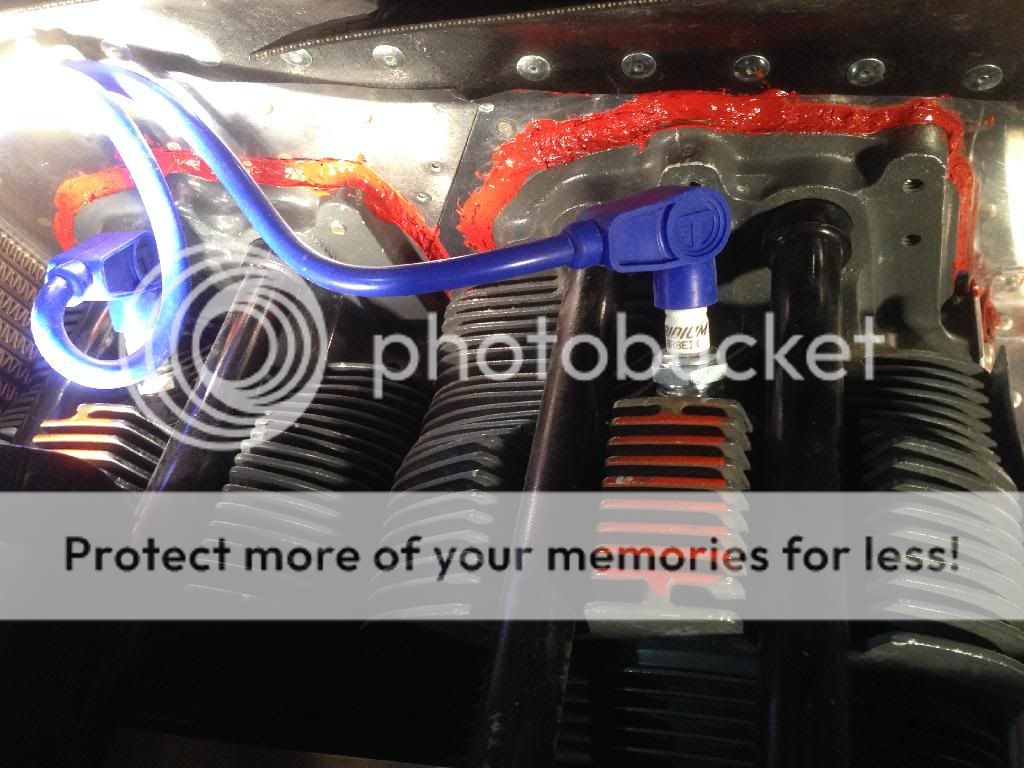

I did find several places that needed some more silicone on my baffling around the top engine mount bolts and on the case inboard of the oil cooler.

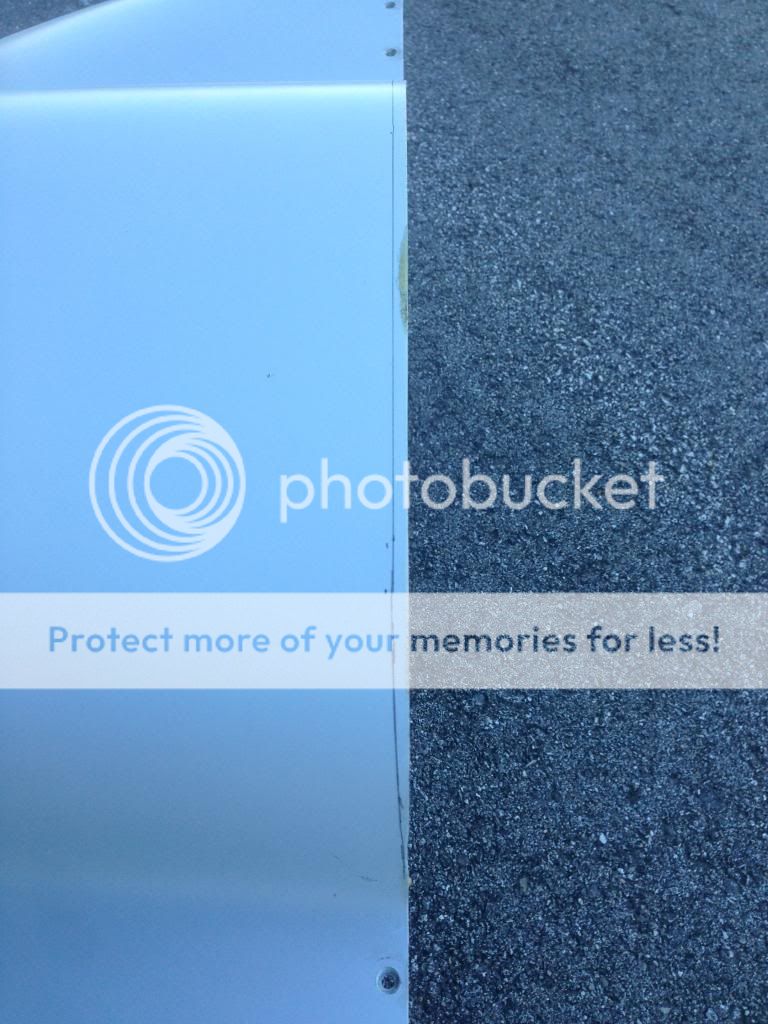

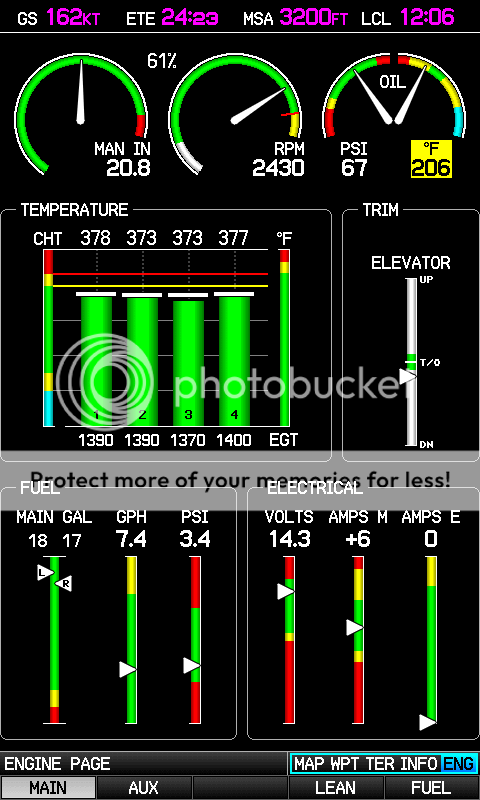

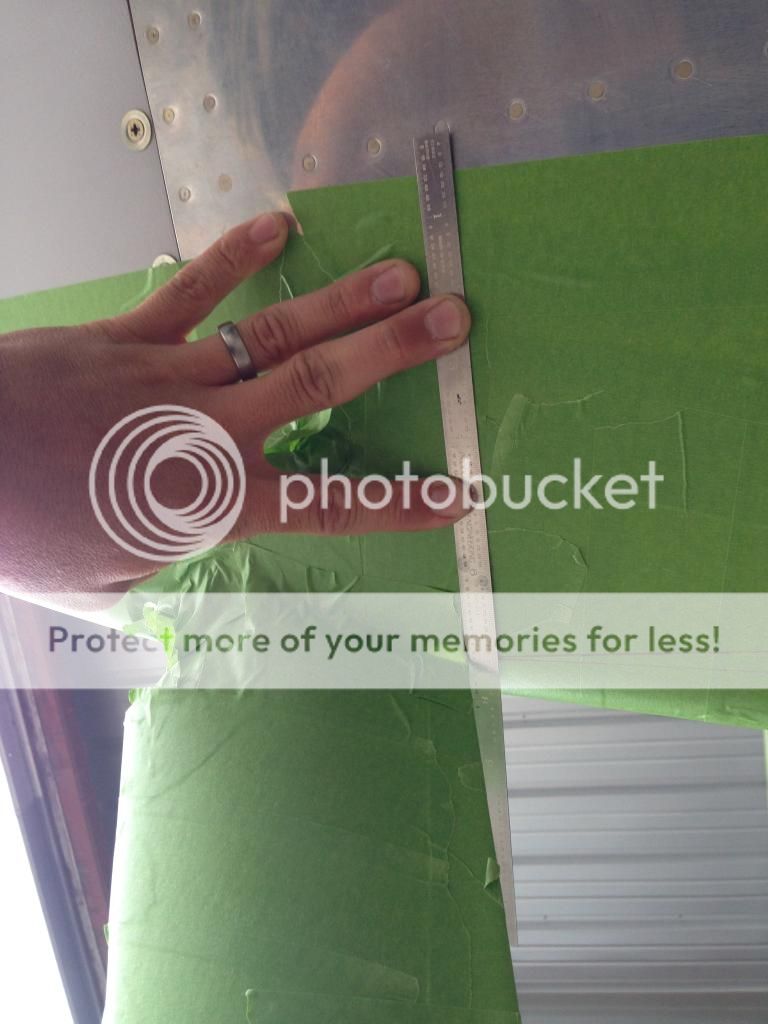

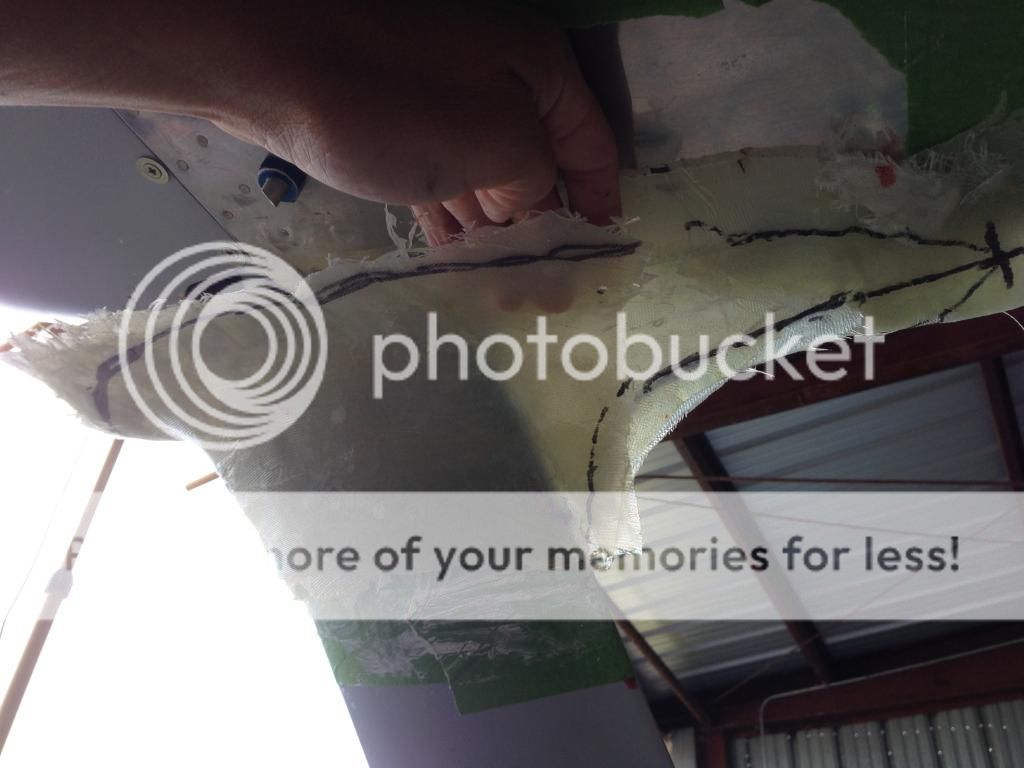

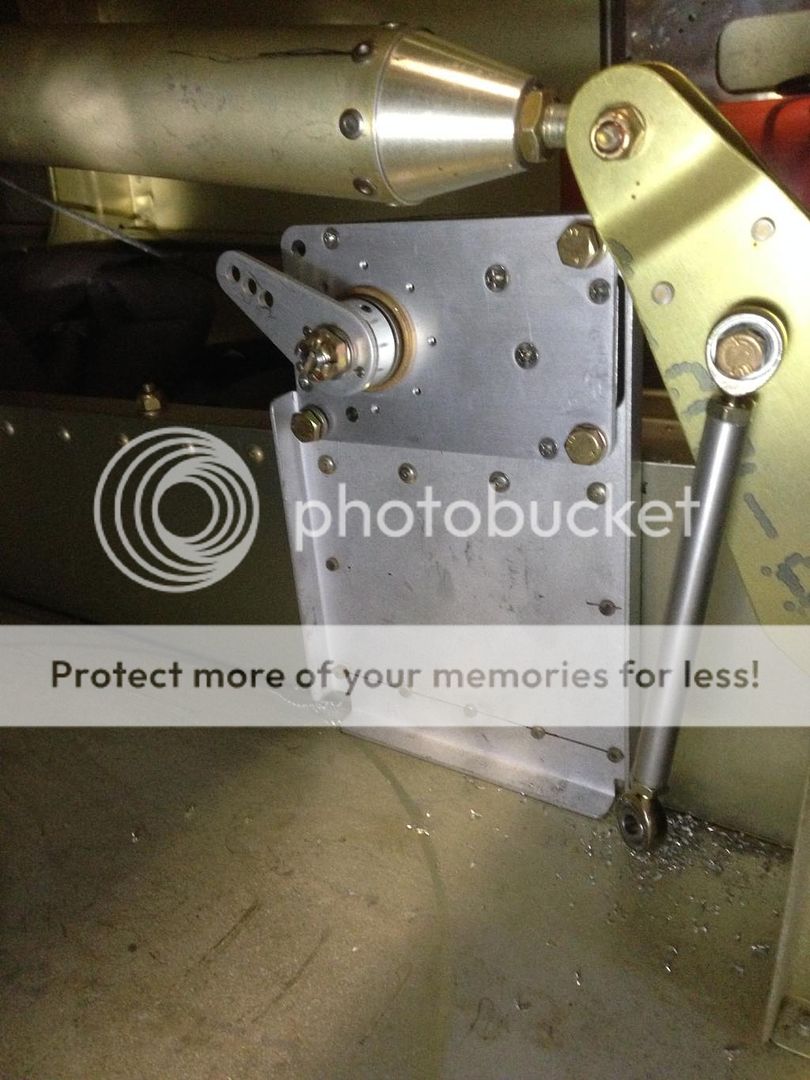

It doesn't take much pressure to push the metal baffling around the rocker covers out to create a leak because of the limited screws holding it to the head. I loosened them up and put a bead of silicone around each head to seal any potential gaps. My initial results are inconclusive so far, temps seem to be running about the same, any benefits are masked by different ambient temps etc. I was expecting 5-10 degree improvement, we'll see.

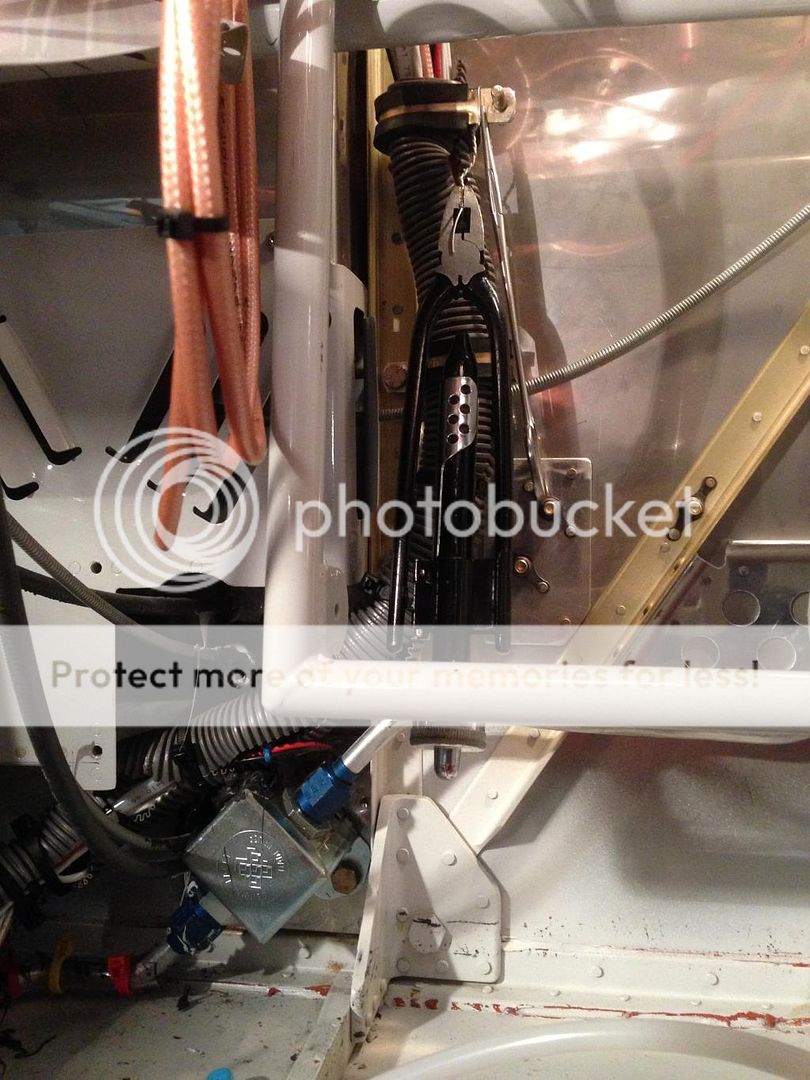

I did find several places that needed some more silicone on my baffling around the top engine mount bolts and on the case inboard of the oil cooler.

It doesn't take much pressure to push the metal baffling around the rocker covers out to create a leak because of the limited screws holding it to the head. I loosened them up and put a bead of silicone around each head to seal any potential gaps. My initial results are inconclusive so far, temps seem to be running about the same, any benefits are masked by different ambient temps etc. I was expecting 5-10 degree improvement, we'll see.