Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Super 8. Documenting an engine overhaul with JB Aircraft

- Thread starter Kahuna

- Start date

Thanks for the pics, especially of JB's operating room!

Kahuna

Moderatoring

Mike, is this essentially the same thing as the "Ney Nozzle"?

- John

Yes. There is an STC for sertified engines for the ney nozzel. Or for us experimental types, JB's positive cam lube jets.

Kahuna

Moderatoring

Is it possible that the rod nuts were installed backwards at first and then reversed?

http://www.lycoming.com/Portals/0/t...I 1458F (03-06-2012)/Connecting Rod Bolts.pdf

Yes Gill I suppose it is. One item we will never know. Definately will go into the life 'headscratcher' bucket.

[email protected]

Member

Is it possible that the rod nuts were installed backwards at first and then reversed?

http://www.lycoming.com/Portals/0/t...I 1458F (03-06-2012)/Connecting Rod Bolts.pdf

Gil I went and looked at the rods again and I think you could be onto something with this. I have a special socket I've modified that makes it a better fit..

Jimmy---awesome job on Kahuna's engine package. Its the little insights to what the experts do that helps all of us.

Tom

Tom

Kahuna

Moderatoring

I didn't see it mentioned, but what was the verdict on the cylinders and LOP ops?

I am going to get the man himself JB to jump in and answer this question.

rocketbob

Well Known Member

I have come up with another mod better than the Ney nozzle. I had an .025 hole EDM'ed in the center of the tappets. Puts oil right where you need it under pressure. Got the idea from here...http://www.claysmithcams.com/edm-solid-flat-tappet/

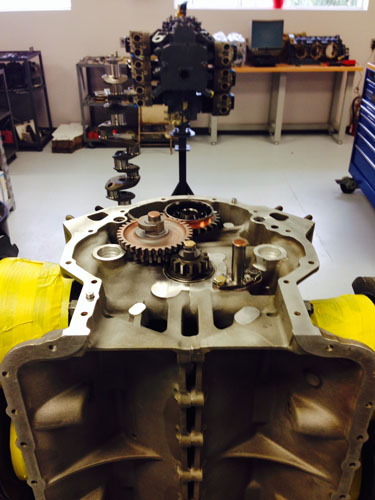

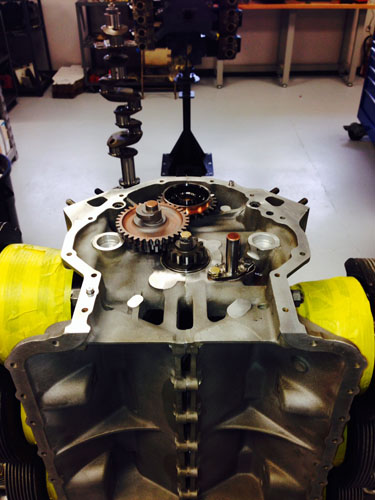

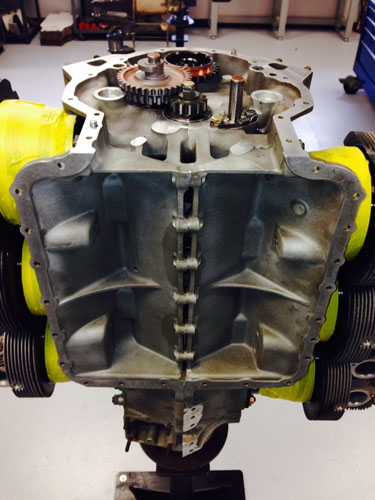

The bigger 540's with the high-volume oil pumps tend to leak on the top split of the case and yes running a 1/16" ball end mill just above the cam will relieve the pressure just enough to prevent that from happening. That trick has been around a while and it works great.

The bigger 540's with the high-volume oil pumps tend to leak on the top split of the case and yes running a 1/16" ball end mill just above the cam will relieve the pressure just enough to prevent that from happening. That trick has been around a while and it works great.

Last edited:

Mike S

Senior Curmudgeon

The crank is also Dynamically Spin Balanced. Counterweights Matched Weights.

It would be interesting to see how they deal with the movable weights for the spin balance.

rocketbob

Well Known Member

This reduces, if not eliminates, those pesky leaks at the thru bolts and reduces the fretting of the cases. At assembly, the case halves get pulled together and the fit is at the dowels. An important item for the next overhauler to know! Since the case will not just fall apart when you remove the thru bolts.

Actually this is an incorrect statement. The reason for the dowels are to bring those holes back up to size, not to prevent leaks. Actually adding a second path around the bushing increases the likelihood of a leak since now there are two paths for the oil to travel. They don't do that to make them stop leaking there. The o-ring counterbore mod is done to prevent leaks.

On the 540 there is an oversize thru bolt available so its just as good to ream the holes to .002 undersize for the larger thru bolt, and then you can counterbore for the o-ring.

So unless one could not ream to fit to size for an oversize thrubolt, I would not do this mod.

Kahuna

Moderatoring

Why is the yellow type around the lower part of the cylinders only?

Its in preparation for paint. The barrels are painted first. Then masked before assembly. Easier to put that on with the cylinders off.

Kahuna

Moderatoring

While pulling off the exhaust, I noticed this warpiage located under the heat muff. Hidden for years. My muffs have never been off and I have had no reason to look under them. Hmmm. Whats that?

A quick call to Larry Vetterman... He has seen this before, although rarely. According to Larry, there are 2 cases where this is seen.

1. A wrapped exhaust, or ceramic coated exhaust. I have neither of these.

2. A muff exit blocked where the heat cant get away, either from a scat tube collapse or FW valve that does not dump overboard. Well I have never had either of those.

Either way, it is what it is. A tap with a punch to check wall thickness in the warpage area and Im satisfied that the warpage does not pose any risk so Im leaving it as is. Amazingly, the rest of the exhaust of completely great. I have never had a crack, support arm break, or anything of that nature in its years of service. Im cleaning it up and putting her back on.

Decided to fix this pipe. Fixing this pipe was not difficult. Im fortunate to have friends and resources on the field here. My star smart guy is Mr. Gary Dehart, retired crew chief Hendrix Motorsports. If he cant do it, it cant be done. We set up a jig on his welding table, cut out the offending piece, & fitted in a new one. The joints are not straight by design. With 321 stainless, you also need very tight butt joints before committing rod to metal. Plus he is a perfectionists. I kept telling him we were not going to the moon here. But there is no convincing him that one day this exhaust might have to see duty on the space station or something. I love hanging out with Gary. I always am humbled and learn from the best. Thanks Gary for sharing your shop today.

During the welding process, a remote pressure argon feeder is installed into the pipe to force out air, and allow for a cleaner weld INSIDE and out.

In the end it looks like a simple straight pipe replacement.

Last edited:

Well its not everyone that has a neighbor like Gary Dehart, a Championship winning Crew Chief in the Cup series. I think its great that he was able and willing to help out. Yep---its cool to be able to watch and learn for masters like him!!!!!

Tom

Tom

Decided to fix this pipe. Fixing this pipe was not difficult. Im fortunate to have friends and resources on the field here. My star smart guy is Mr. Gary Dehart, retired crew chief Hendrix Motorsports. If he cant do it, it cant be done. We set up a jig on his welding table, cut out the offending piece, & fitted in a new one. The joints are not straight by design. With stainless, you also need very tight butt joints before committing rod to metal. Plus he is a perfectionists. I kept telling him we were not going to the moon here. But there is no convincing him that one day this exhaust might have to see duty on the space station or something. I love hanging out with Gary. I always am humbled and learn from the best. Thanks Gary for sharing your shop today.

His welding hood speaks volumes too. Me likee!!!

[email protected]

Member

Case Dowels / Orings / Thru-Bolts

I agree that the installation of the dowels is an approved repair for excessive wear at the thru bolt hole main bearing area. If the interference fit is diminished (Fretting occurs at the center mains) then thru bolts leak and a repair is required. As you suggest a basic mod is available (Lycoming) to improve leaking by only installing an oversized thru bolt and machining an o-ring groove in the case to fit around the thru bolt only. This repair is an approved fix that works for low horsepower engines but never holds up for long on higher horsepower engines.

In the past 30 years we found that with the installation of the center dowels and most important the addition of an o-ring groove around the dowel works best as a proper prevention and repair for case fretting. This improved modification results in improved leak prevention. These two Lycoming Service Instructions cover some of this information SI 1290 / SI 1123

I'm sure that opinions from engine builders may vary on this subject and no disrespect to rocket or his opinion/experience building engines..

Any questions [email protected]

Actually this is an incorrect statement. The reason for the dowels are to bring those holes back up to size, not to prevent leaks. Actually adding a second path around the bushing increases the likelihood of a leak since now there are two paths for the oil to travel. They don't do that to make them stop leaking there. The o-ring counterbore mod is done to prevent leaks.

On the 540 there is an oversize thru bolt available so its just as good to ream the holes to .002 undersize for the larger thru bolt, and then you can counterbore for the o-ring.

So unless one could not ream to fit to size for an oversize thrubolt, I would not do this mod.

I agree that the installation of the dowels is an approved repair for excessive wear at the thru bolt hole main bearing area. If the interference fit is diminished (Fretting occurs at the center mains) then thru bolts leak and a repair is required. As you suggest a basic mod is available (Lycoming) to improve leaking by only installing an oversized thru bolt and machining an o-ring groove in the case to fit around the thru bolt only. This repair is an approved fix that works for low horsepower engines but never holds up for long on higher horsepower engines.

In the past 30 years we found that with the installation of the center dowels and most important the addition of an o-ring groove around the dowel works best as a proper prevention and repair for case fretting. This improved modification results in improved leak prevention. These two Lycoming Service Instructions cover some of this information SI 1290 / SI 1123

I'm sure that opinions from engine builders may vary on this subject and no disrespect to rocket or his opinion/experience building engines..

Any questions [email protected]

rocketbob

Well Known Member

Not disagreeing but if it were my engine and the studs were necessary I would do both. That is, put the o-ring counterbore in along with the stud, and use a larger oring. On the high HP 540's usually at the third main where you see the most fretting/throughbolt hole wear, the others are usually fine.

Kahuna

Moderatoring

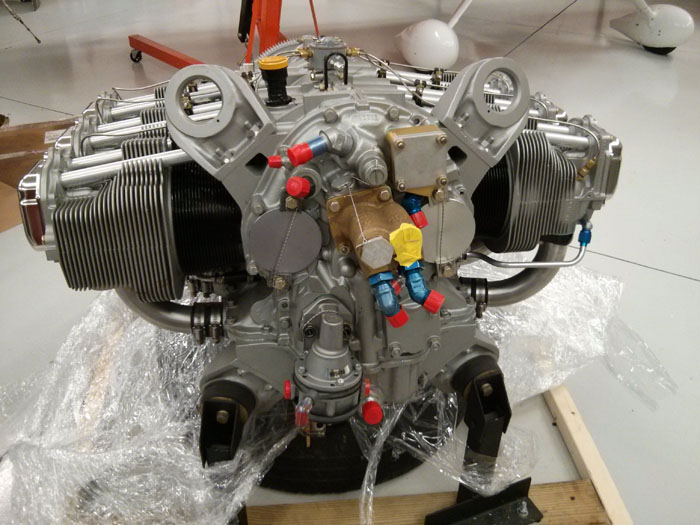

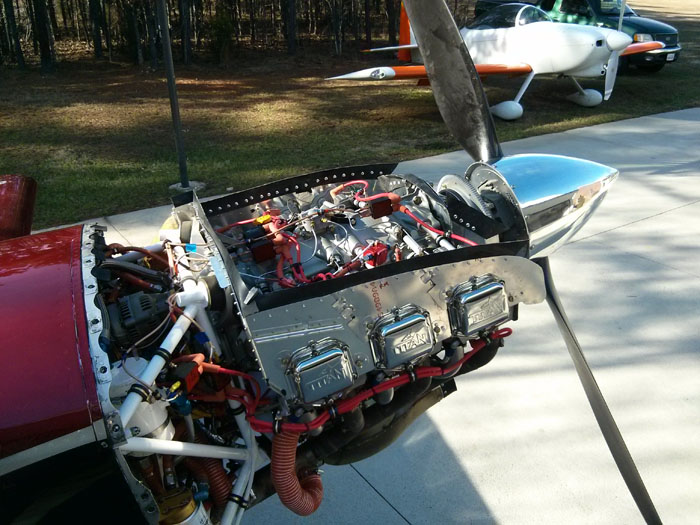

Engine arrives

The engine was shipped Yellow Freight. Took 24 hours to get from Sebring to Charlotte for me to pick up. Thats pretty fast trucking. My wife Amy picked it up for me on her way to work 5 days ago. She is very supportive. YF placed it in the truck with a forklift. It arrived all created up. A little rain shower on the drive home.

Getting it off the truck can be a bit tricky. My hoist is no where near tall enough to snag it off the truck. So I put my by-fold door power to use. The dogs are not as enthusiastic as I was.

Upon unwrapping, I found this beautiful engine. We have installed 4 new engines on the team this year. Looking at these new motors never gets old.

JB asked me what I wanted for colors. I told him he could surprise me with anything other than pink! It is purtty. He swapped over some of my old accessories like my starter, governor, remote oil adapter, inverted oil adapter, etc. New injection lines and the rebuilt spider and servo. It was time to get to work. Fights on!

The engine was shipped Yellow Freight. Took 24 hours to get from Sebring to Charlotte for me to pick up. Thats pretty fast trucking. My wife Amy picked it up for me on her way to work 5 days ago. She is very supportive. YF placed it in the truck with a forklift. It arrived all created up. A little rain shower on the drive home.

Getting it off the truck can be a bit tricky. My hoist is no where near tall enough to snag it off the truck. So I put my by-fold door power to use. The dogs are not as enthusiastic as I was.

Upon unwrapping, I found this beautiful engine. We have installed 4 new engines on the team this year. Looking at these new motors never gets old.

JB asked me what I wanted for colors. I told him he could surprise me with anything other than pink! It is purtty. He swapped over some of my old accessories like my starter, governor, remote oil adapter, inverted oil adapter, etc. New injection lines and the rebuilt spider and servo. It was time to get to work. Fights on!

Kahuna

Moderatoring

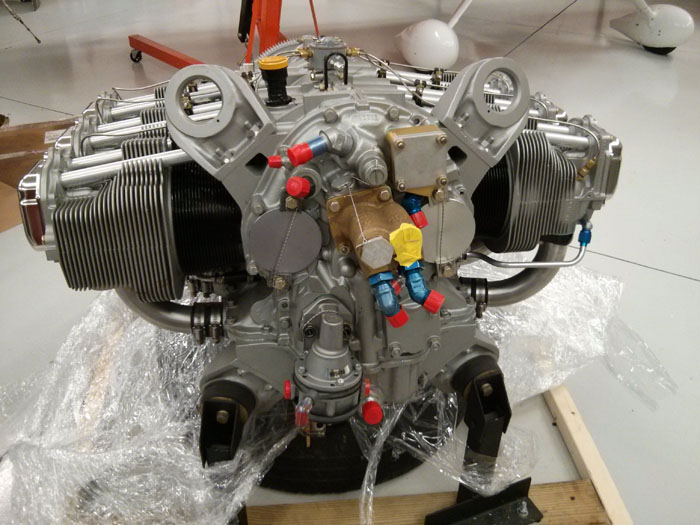

Heat mod

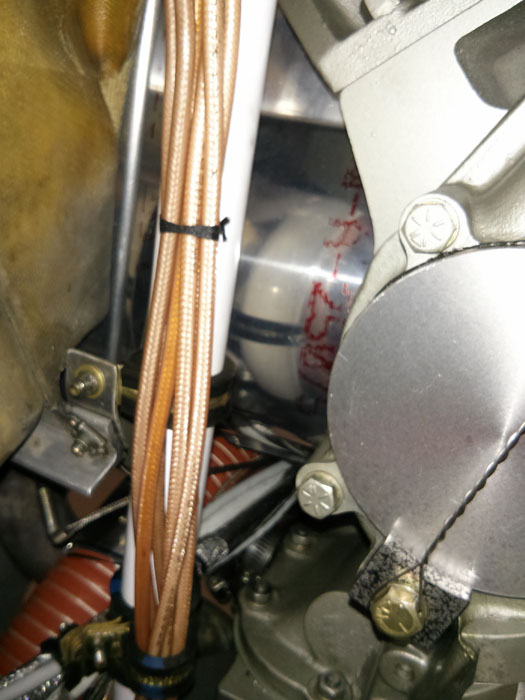

During my original build, I came up with the idea to pick up the fresh air for the heat muffs from the intercylinder baffles below the cylinders. I had a few things in mind with this.

1. Big engine, more heat, no change in inlet sq inches. I did not want to rob cold air off the rear baffles for heat.

2. Seemed like a good idea to pull heat from the warmer air that has already been warmed by the cylinder fins.

3. I could think of no downside.

This served me well over the years with plentiful heat even in sub zero conditions. The mod is pretty simple. Rivet a 2" flange to the intercylinder baffle and install. I could not reuse the ones from my lyco cylinders as the Titan tapered finned cylinders are a bit different. It does require some rebending of the valve cover drain lines that return oil back to the sump.

You will notice below that the cylinder wrap is safety wired to the cht probe insert on the right side of the picture. This is necessary since you cant tie the 2 wrappes together with that big 2" flange in the way. I had no problems with this in the first 2000 hours so I consider this a good working solution.

I forgot to take a picture of the final install but it looks just like my original one below.

During my original build, I came up with the idea to pick up the fresh air for the heat muffs from the intercylinder baffles below the cylinders. I had a few things in mind with this.

1. Big engine, more heat, no change in inlet sq inches. I did not want to rob cold air off the rear baffles for heat.

2. Seemed like a good idea to pull heat from the warmer air that has already been warmed by the cylinder fins.

3. I could think of no downside.

This served me well over the years with plentiful heat even in sub zero conditions. The mod is pretty simple. Rivet a 2" flange to the intercylinder baffle and install. I could not reuse the ones from my lyco cylinders as the Titan tapered finned cylinders are a bit different. It does require some rebending of the valve cover drain lines that return oil back to the sump.

You will notice below that the cylinder wrap is safety wired to the cht probe insert on the right side of the picture. This is necessary since you cant tie the 2 wrappes together with that big 2" flange in the way. I had no problems with this in the first 2000 hours so I consider this a good working solution.

I forgot to take a picture of the final install but it looks just like my original one below.

Kahuna

Moderatoring

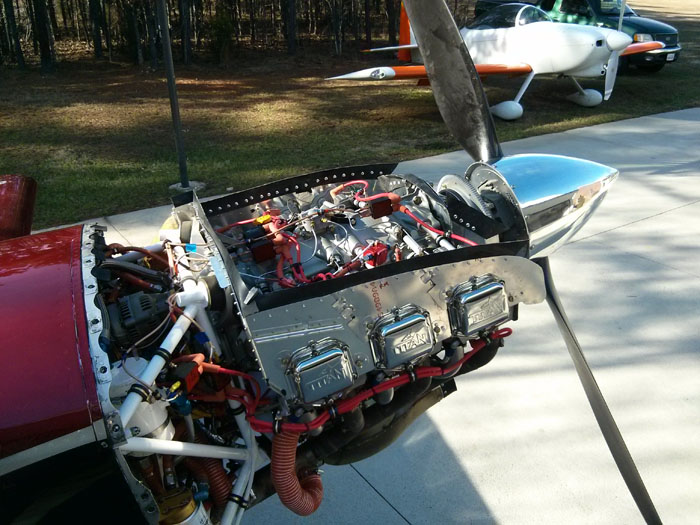

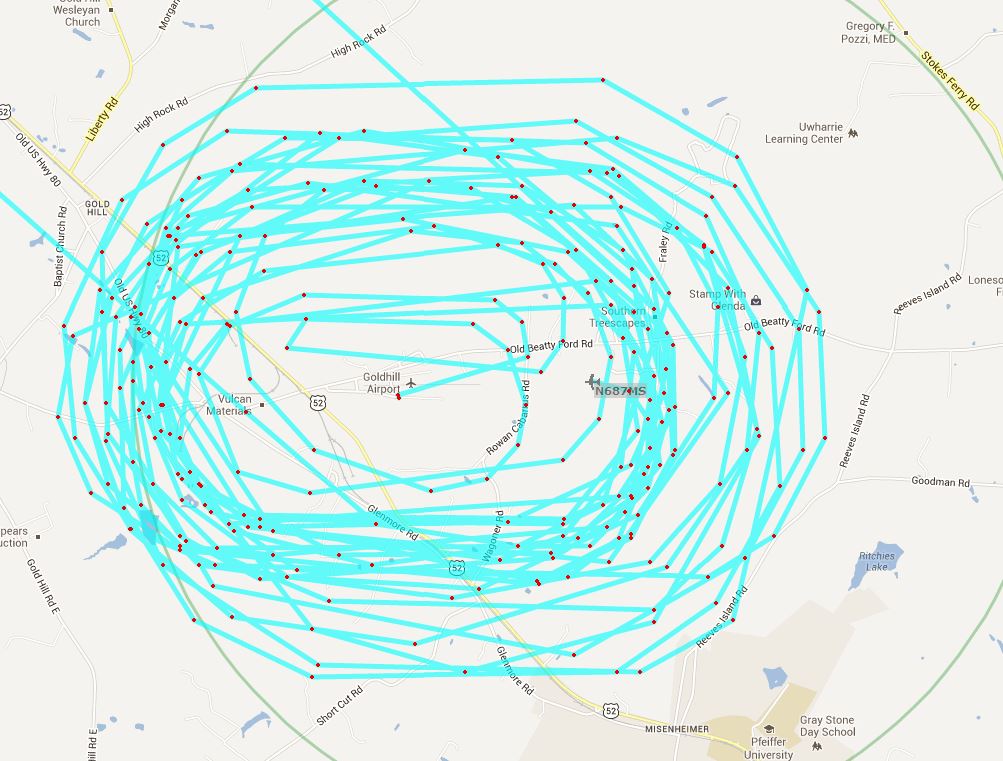

Back in the air

After 5 days of work, plus stick in family time at xmas, my wonderful super 8 is back in the air. Everything fit back to where it was. I had one kinked oil line that Tom at TS Flightlines immediately rectified. Thanks Tom! Baffles are new. Geez I hate baffle work. Sealed up every nook and cranny with black RTV. Only issue I had on initial start was 2 plug wires reversed. I can live with that. Put 2 uneventful hours on her today. Fuel flow was a staggering 25gph. I cant even look at it. Cool temps here kept cyl temps below 330. Thats pretty good given brand new cylinders.

I cant even look at it. Cool temps here kept cyl temps below 330. Thats pretty good given brand new cylinders.

This is what it looks like to break in an engine. Dizzy!

Everything works. Nothing to do now by fly it hard and fly it fast.

After 5 days of work, plus stick in family time at xmas, my wonderful super 8 is back in the air. Everything fit back to where it was. I had one kinked oil line that Tom at TS Flightlines immediately rectified. Thanks Tom! Baffles are new. Geez I hate baffle work. Sealed up every nook and cranny with black RTV. Only issue I had on initial start was 2 plug wires reversed. I can live with that. Put 2 uneventful hours on her today. Fuel flow was a staggering 25gph.

This is what it looks like to break in an engine. Dizzy!

Everything works. Nothing to do now by fly it hard and fly it fast.

rvatorsteve

I'm New Here

Your airplane looks great! Do you know how many Super RV-8s are flying? Are there any plans or parts out there?

Kahuna

Moderatoring

Your airplane looks great! Do you know how many Super RV-8s are flying? Are there any plans or parts out there?

You can start here.

http://mstewart.net/super8/faq.htm

AlexPeterson

Well Known Member

Mike, that took some serious hours to mount it all up in 5 days! Nice looking install.

Weasel

Well Known Member

bump

Would like to hear comments on this negative or positive. Always wanting to learn more.

I am going to get the man himself JB to jump in and answer this question.

Would like to hear comments on this negative or positive. Always wanting to learn more.

BSwayze

Well Known Member

Kanuna, I'm very interested in your oil cooler mount, seen in this picture. It's hard to see much in the way of details. Where did you get this? Is it fiberglass? Did you make it yourself?

Any comments or further information, especially after all of your experience with it? Much appreciated, thanks.

Kahuna

Moderatoring

Kanuna, I'm very interested in your oil cooler mount, seen in this picture. It's hard to see much in the way of details. Where did you get this? Is it fiberglass? Did you make it yourself?

Any comments or further information, especially after all of your experience with it? Much appreciated, thanks.

Yes I made it. My goal was to hard mount the cooler to the engine mount using adel clamps. Tilted back a bit to get the air heading out of the cowl. Then I used foam to mock up the transition to the rear baffle. Laid up fiberglass.

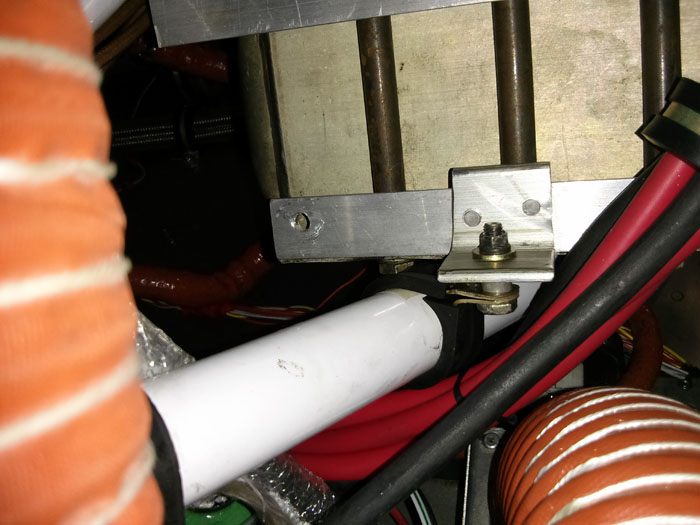

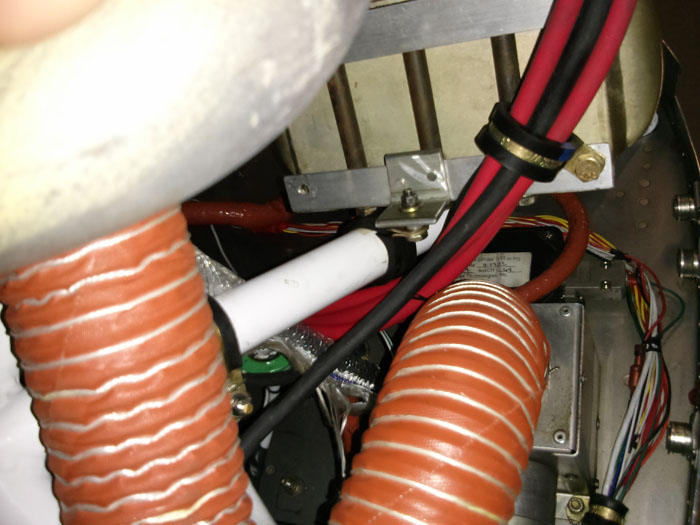

Since I live with my plane, I took some pictures for you of the mounting setup I use. This has survived 2k hours and I believe will survive another 2k hours with no problems.

Starting from the top left. You can see some alum angle bolted to the cooler, and the first of 4 mounting locations.

Moving to the top right, this is hard mounted to the firewall.

Next is the bottom center.

And finally the bottom right, which is hard to get a picture of. There is a downtube of the engine mount in the center of the picture and the mount is to the left of the coax. This is a top down view of the bottom right mount.

And the same mount looking up from the bottom.

I hope this was useful. Note: This engine mount is for a Super 8. Different geometry. All other mounts are different. Exactly where you mount and how you attached will be a bit different but the concepts are the same.

Kahuna

Moderatoring

kahuna, that is one nice xmas present. happy new year and many safe flying hours. great education on engines. do you have a final tally on the entire project? has it gone upside down yet?

Thanks to our team partners, JB Aircraft

I spent ~$700 to overhaul AFP servo, spider and new injection lines.

~$400 on new ignition wires and plugs from Lightspeed.

A few hundred dollars in odds and ends like adel clamps and things.

Kahuna

Moderatoring

Hi Kahuna, Did I miss it? Was looking for what your mechanic thought about all the LOP hours

Ill get him on this. He has been recovering from a holiday of fishing with his boys. Thanks for reminding me.

Kahuna

Moderatoring

Running strong

Update:

The engine is doing very well with about 6 hours now. Im fiddling with flow matching injectors, and even cht distribution. I also have one pesky mag cover bolt oil leak. One of the items that took some fiddling was the timing.

I run dual LSE ignitions with a direct crank pickup. As a result of increased compression, the timing needs to be adjusted a bit. The bad news it that in order to do this, its a complete prop pull. Which on a fixed pitched prop, no problem. But these c/s props, well, its a finger chore. Since the original 8.7:1 compression was a 25deg timing, and the new timing needs to be 20, this required either a set of computer swaps, or a board adjustment. I choose the later.

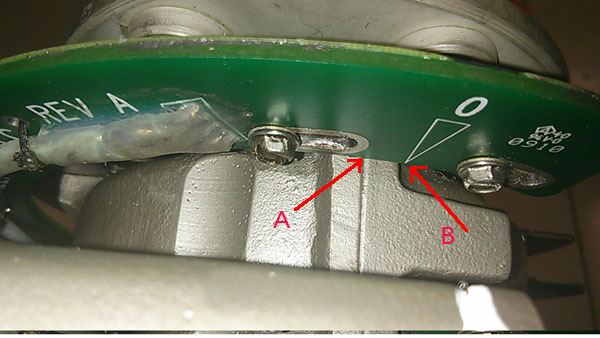

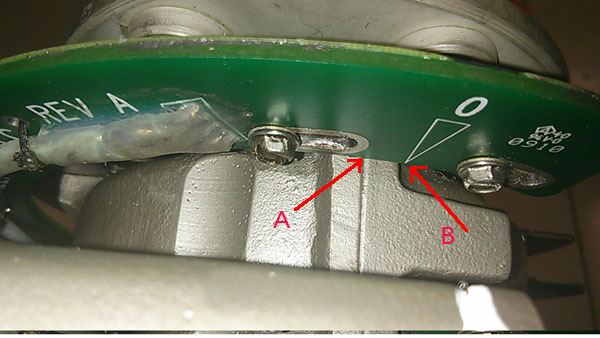

In the picture below, taken from above the engine, looking down and fwd on the case at the nose, crank flange is at the top of the picture, you can see item mark A is the case split. Normally you line up the case split with the arrow on the board marked B. These 2 were lined up in the original set up. To retard the timing from 25 to 20 (make it fire later in the stroke, Later equals retarded and earlier equals advanced. Why they make this verbiage so confusing is beyond me), simple move the board in its mount slots. Thats the good news. The bad news is that its not that easy to know exactly how much movement there needs to be to capture the timing you want. Its a swag. And the only way to know exactly what timing you have is with a timing light. Thats a prop off, board move, prop on, test, prop off, board move until done activity.

In this picture I went from 25 to 18. Rats. Went to far. I settled in on half the distance.

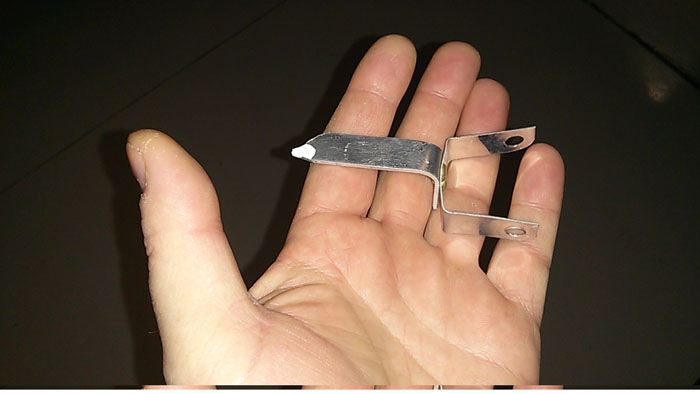

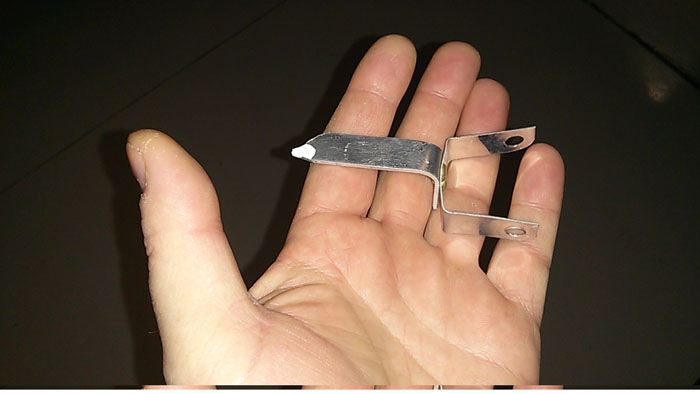

NOTE: measuring the timing with a timing light is rather difficult on a tail dragger. Your up on a step stool behind the prop with the engine running pointing your timing light fwd to the aft side of the ring gear, looking for the case split and the ring gear marks you marked with white paint, doing the best you can trying to eyeball a line up. Praying that you don't slip and fall and kill yourself. I ended up making a pointing device out of scrap aluminum that bolts to the case and gives me a physical pointer right up to the ring gear face markers so that I know EXACTLY what the timing is. I should have made one of these long ago. It makes the entire effort safer, and more accurate. With this I can stand along side of the engine with the timing light and get very accurate readings. Remember, with these electronic ignitions, there is only ONE way to know that the timing really is, and thats with a timing light on the ring gear.

Update:

The engine is doing very well with about 6 hours now. Im fiddling with flow matching injectors, and even cht distribution. I also have one pesky mag cover bolt oil leak. One of the items that took some fiddling was the timing.

I run dual LSE ignitions with a direct crank pickup. As a result of increased compression, the timing needs to be adjusted a bit. The bad news it that in order to do this, its a complete prop pull. Which on a fixed pitched prop, no problem. But these c/s props, well, its a finger chore. Since the original 8.7:1 compression was a 25deg timing, and the new timing needs to be 20, this required either a set of computer swaps, or a board adjustment. I choose the later.

In the picture below, taken from above the engine, looking down and fwd on the case at the nose, crank flange is at the top of the picture, you can see item mark A is the case split. Normally you line up the case split with the arrow on the board marked B. These 2 were lined up in the original set up. To retard the timing from 25 to 20 (make it fire later in the stroke, Later equals retarded and earlier equals advanced. Why they make this verbiage so confusing is beyond me), simple move the board in its mount slots. Thats the good news. The bad news is that its not that easy to know exactly how much movement there needs to be to capture the timing you want. Its a swag. And the only way to know exactly what timing you have is with a timing light. Thats a prop off, board move, prop on, test, prop off, board move until done activity.

In this picture I went from 25 to 18. Rats. Went to far. I settled in on half the distance.

NOTE: measuring the timing with a timing light is rather difficult on a tail dragger. Your up on a step stool behind the prop with the engine running pointing your timing light fwd to the aft side of the ring gear, looking for the case split and the ring gear marks you marked with white paint, doing the best you can trying to eyeball a line up. Praying that you don't slip and fall and kill yourself. I ended up making a pointing device out of scrap aluminum that bolts to the case and gives me a physical pointer right up to the ring gear face markers so that I know EXACTLY what the timing is. I should have made one of these long ago. It makes the entire effort safer, and more accurate. With this I can stand along side of the engine with the timing light and get very accurate readings. Remember, with these electronic ignitions, there is only ONE way to know that the timing really is, and thats with a timing light on the ring gear.

Last edited:

Ill get him on this. He has been recovering from a holiday of fishing with his boys. Thanks for reminding me.

Mike, I've really enjoyed following your story here. By chance, have you been able to chat with Jim B about his present opinion of running LOP???

Thank you and best regards,

jthocker

Well Known Member

Yes I have talked to him and he has expressed that he is not a LOP fan. Getting him to come here to discuss it has been difficult.

Not to mention the fact, that Jimmy has a business to run, and getting into an internet discussion here would be a no win situation and would gobble up a huge amount of time!

hgerhardt

Well Known Member

Don't pull the prop

No, it's not necessary to pull the prop to re-time the LSE crank trigger. I've done it on mine, with that same "REV 1" trigger board as Mike has. I'm not saying it's easy, but it is doable with less work than pulling the prop.

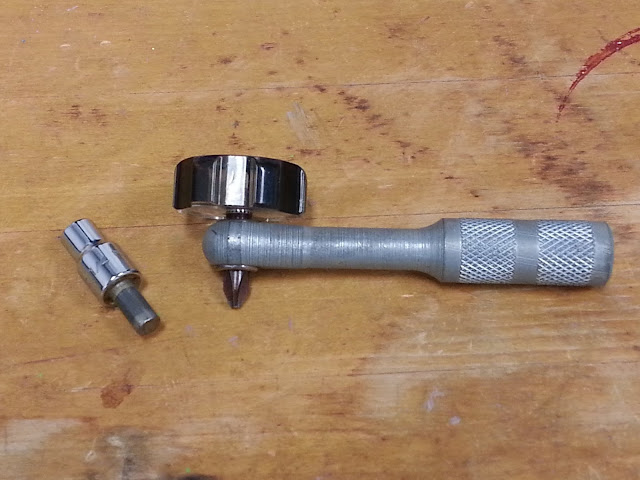

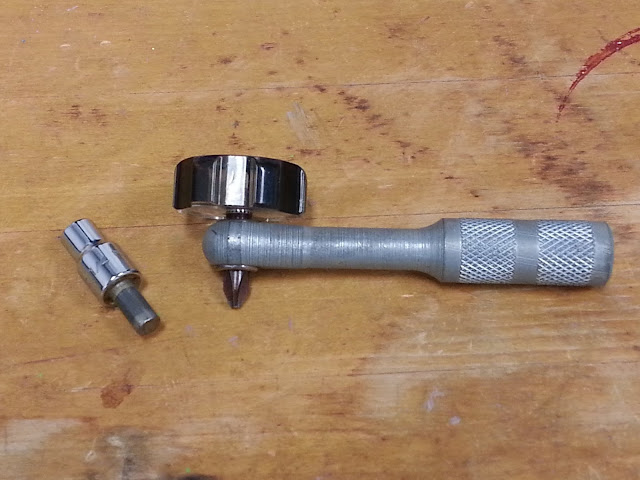

I use a right angle screwdriver to hold a 1/4" socket that I modified by bonding in a piece of 1/4" round stock (a sawed-off AN bolt works). I roughed up the end of the bolt to be bonded within the socket to keep it from spinning within the glue, but you don't want much torque for those small screws and the glue works well. Since the locking mechanism in the handle is a sprag clutch, it takes almost no movement of the handle to get useful rotation.

To see what you're doing, use a 2" dia inspection mirror.

Heinrich

...the timing needs to be adjusted a bit. The bad news it that in order to do this, it's a complete prop pull...

No, it's not necessary to pull the prop to re-time the LSE crank trigger. I've done it on mine, with that same "REV 1" trigger board as Mike has. I'm not saying it's easy, but it is doable with less work than pulling the prop.

I use a right angle screwdriver to hold a 1/4" socket that I modified by bonding in a piece of 1/4" round stock (a sawed-off AN bolt works). I roughed up the end of the bolt to be bonded within the socket to keep it from spinning within the glue, but you don't want much torque for those small screws and the glue works well. Since the locking mechanism in the handle is a sprag clutch, it takes almost no movement of the handle to get useful rotation.

To see what you're doing, use a 2" dia inspection mirror.

Heinrich