Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

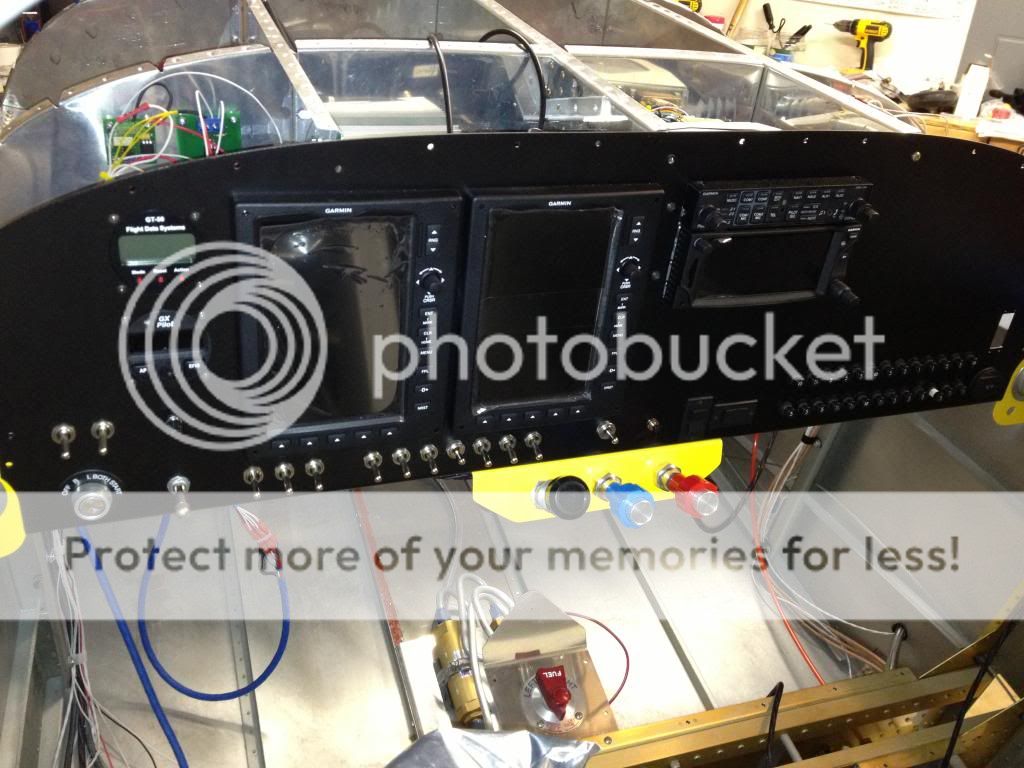

N159SB G3X Panel Upgrade Status

- Thread starter Brantel

- Start date

Uh, Stein, I don't see a Stein-Air T-Shirt in that box. Could it be because you already have all his money?

As one of our other shirts says..."He's broke, we're happy"!

Cheers,

Stein

Brantel

Well Known Member

I think I would rather hand wire the entire panel, with Klick on breakers, that try to decipher that computer gobblegook in post 44

It is way easier than you might think....

ColoRv

Well Known Member

As one of our other shirts says..."He's broke, we're happy"!

Cheers,

Stein

I too resemble that remark. :-(

But the par100ex showed up today....a day early!

Brantel

Well Known Member

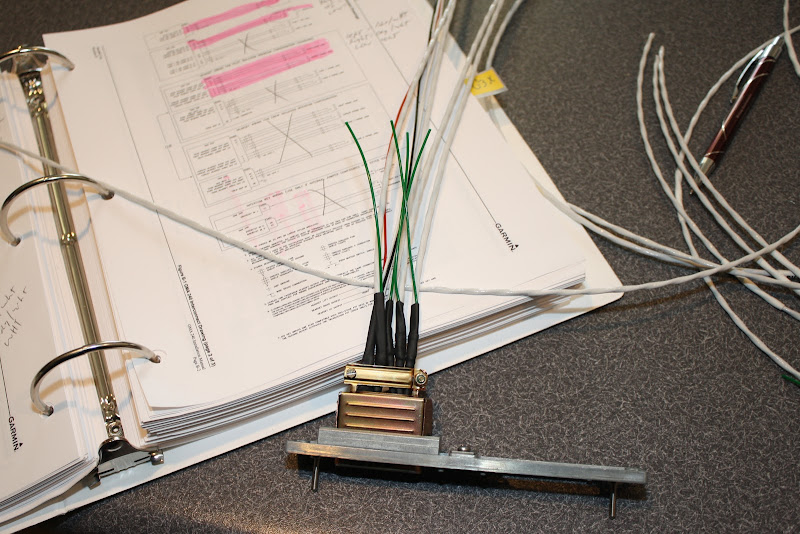

Tonight I set out to complete the VP-X Pro harnesses. I started out at the hangar and it was too cold over there so I brought the stuff home.

Pretty basic, one wire at a time stuff.

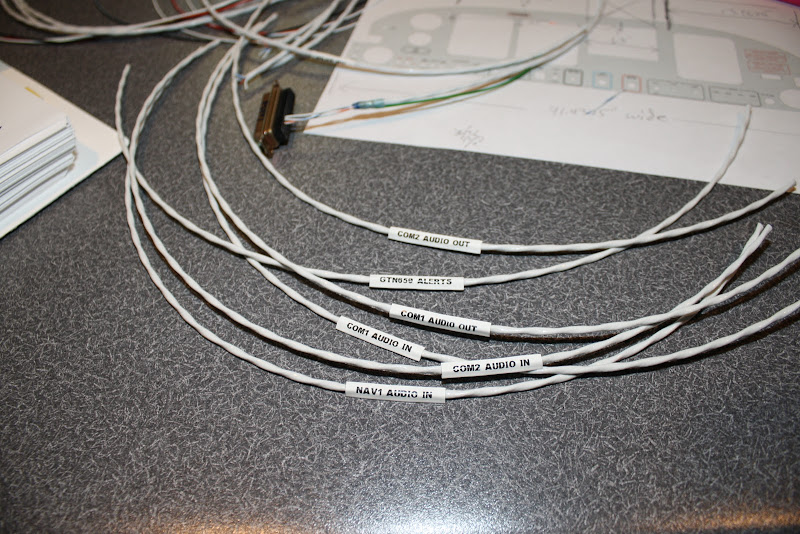

Labeled both ends of the wire for future reference using thermal heat shrink tube labels. Most wires are just stubs that will get spliced back into the old parts of the harness left in the airplane. J1 and J2 are complete. The power plugs will get the avionics feeds added to them later.

Here are the fruits of my labor tonight:

Pretty basic, one wire at a time stuff.

Labeled both ends of the wire for future reference using thermal heat shrink tube labels. Most wires are just stubs that will get spliced back into the old parts of the harness left in the airplane. J1 and J2 are complete. The power plugs will get the avionics feeds added to them later.

Here are the fruits of my labor tonight:

Last edited:

rleffler

Well Known Member

Can you be more specific on the thermal heat shrink tube labels? Brand? Size? and which machine? Maybe a source as well?

Inquiring (lazy) minds want to know

I have a dymo Rhino 5000, which was updated to a 5200 this past year. There are other brands that do similiar heat shrink tubes.

You can get these from a variety of sources. When I purchased mine many years ago, these guys offered the best prices. http://www.labelcity.com/Dymo-Rhino-RhinoPro/Rhino-Printers-Labelers/

I've been buying replacements from Amazon recently, primarily since I'm lazy and have a prime account.

1/4" works well even on 22awg. I use 3/8" for shielded twisted pair. Be forewarned, the heat shrink tubes aren't inexpensive. There are less expensive alternatives, but it my opinion don't look as nice. You find a multitude of opinions on this subject.

Last edited:

Brantel

Well Known Member

Can you be more specific on the thermal heat shrink tube labels? Brand? Size? and which machine? Maybe a source as well?

Inquiring (lazy) minds want to know

Panduit LS8E label printer (that Green thing with all the buttons in the pic) with Panduit cartridges. You can get em in all sorts of sizes and a few colors.

This system is not cheap however and the cartridges are not cheap either.

I borrowed the printer from my work and bought a couple cartridges.

If I were to be the market to buy a system, I would get a cheaper one than the Panduit models.

Like Bob says, the results are super great but it is not the least expensive option, if I had not been able to borrow the printer, I would do something else just due to the cost.

Why hasn't some enterprising builder/label maker owner set up his 12 year old making labels for fun and profit? Seems like a win-win for Dad to recoup his big cash outlay and help defray allowance costs at the same time. Idle hands are the devil's tools, don't you know? Holler when you get the business up and running and I'll be your first customer.

Jim

Sweet Pea RV-8A

Mustang Sally On the gear.

Jim

Sweet Pea RV-8A

Mustang Sally On the gear.

Brantel

Well Known Member

Brian,

I got mine before you got yours!!! Nanny nanny boo boo!!

Stein had better not be sending you a t-shirt, I didn't get one. All I have is some lousy (nice looking) key chains!

Very nice!

Last edited:

Fearless

Well Known Member

Your killing me

You guys are killing me with your high dollar panel upgrades. I'm trying to skimp up enough cash to buy my second EFIS on my panel so my daughter can see what the heck is going on when she flys with me (if I ever get done with the build). I do anticipate panel changes in the future so I have a slider blank for when that time comes.

I have to admit that if I had the bucks I would be right with you on the Garmin panel. I have always liked that setup since I first saw it in the Skycatcher.

You guys are killing me with your high dollar panel upgrades. I'm trying to skimp up enough cash to buy my second EFIS on my panel so my daughter can see what the heck is going on when she flys with me (if I ever get done with the build). I do anticipate panel changes in the future so I have a slider blank for when that time comes.

I have to admit that if I had the bucks I would be right with you on the Garmin panel. I have always liked that setup since I first saw it in the Skycatcher.

Last edited:

Walt

Well Known Member

You guys are killing me with you high dollar panel upgrades. I'm trying to skimp up enough cash to buy my second EFIS on my panel so my daughter can see what the heck is going on when she flys with me (if I ever get done with the build).

Uh oh... I still have round instruments, my panel may be obsolete but I'm still faster than all my buddies

Last edited:

humptybump

Well Known Member

Walt, don't worry about the technology in your panel. The world is scheduled to end in 9 days and Brian won't get a chance to fly his new panel.

Brian's new panel is sure to be wonderful.

Mike - like you, I'm going the "upgradable panel" path.

This thread is both a good and fun read!

Brian's new panel is sure to be wonderful.

Mike - like you, I'm going the "upgradable panel" path.

This thread is both a good and fun read!

Brantel

Well Known Member

Here is the proposed wiring diagram for my backup/aux power system:

click for big version:

The backup battery will get charged anytime the master is on. The typical startup work flow will be to close the Aux Battery feed switch first thing to get the EFIS and EMS up and running before start. This switch will remain on till shutdown.

Charge current is limited by the 10ohm 20W resistor. The VP-X Pro takes care of monitoring the backup batteries voltage level.

Distributed over-current protection is provided by both inline fuses and the 6 fuse block.

The Schottky diodes take care of ensuring current flow in the correct directions and to power up the Gemini which does not have a built in backup power pin. The G3X system has backup power pins.

I ended up ordering this battery from BatteryMart.com:

They had hundreds of good reviews on this battery and I have ordered from them before with good service. This appears to be a high volume battery for them so hopefully I will get a fresh one....

click for big version:

The backup battery will get charged anytime the master is on. The typical startup work flow will be to close the Aux Battery feed switch first thing to get the EFIS and EMS up and running before start. This switch will remain on till shutdown.

Charge current is limited by the 10ohm 20W resistor. The VP-X Pro takes care of monitoring the backup batteries voltage level.

Distributed over-current protection is provided by both inline fuses and the 6 fuse block.

The Schottky diodes take care of ensuring current flow in the correct directions and to power up the Gemini which does not have a built in backup power pin. The G3X system has backup power pins.

I ended up ordering this battery from BatteryMart.com:

They had hundreds of good reviews on this battery and I have ordered from them before with good service. This appears to be a high volume battery for them so hopefully I will get a fresh one....

humptybump

Well Known Member

Doing some quick math (often a dangerous thing) ...

The 10 ohm resistor in your charging circuit is pretty large. According to an EE I consulted for the same topic, here is what I got ...

If I use your 10 ohm resistor, as assume a backup battery below usable voltage - say 4.8V - I get the following ...

10 = (Va-Vb) / Ic

10 = (14.8 - 4.8) / Ic

10 = 10 / Ic

Your Ic (charge current) is 1A.

The 10 ohm resistor in your charging circuit is pretty large. According to an EE I consulted for the same topic, here is what I got ...

Va = alternator voltage

Vb = minimum battery voltage at discharge

Ic = desired charge current

then you have R = (Va-Vb) / Ic

So if your alternator outputs, say, 14.8 volts and the battery has discharged to 11.8 volts and you want a maximum of 2 amps charge current, 14.8-11.8=3, 3/2=1.5, so you'd need a 1.5 ohm resistor.

If you were to actually start a charge from the maximum discharge voltage on the battery, you'd be dissipating 6+ watts in this configuration until the battery voltage starts coming up.

As the battery voltage comes up, of course, the change current drops off until it reaches essentially zero when the battery equals the alternator output.

If I use your 10 ohm resistor, as assume a backup battery below usable voltage - say 4.8V - I get the following ...

10 = (Va-Vb) / Ic

10 = (14.8 - 4.8) / Ic

10 = 10 / Ic

Your Ic (charge current) is 1A.

Last edited:

Brantel

Well Known Member

Doing some quick math (often a dangerous thing) ...

The 10 ohm resistor in your charging circuit is pretty large. According to an EE I consulted for the same topic, here is what I got ...

If I use your 10 ohm resistor, as assume a backup battery below usable voltage - say 4.8V - I get the following ...

10 = (Va-Vb) / Ic

10 = (14.8 - 4.8) / Ic

Your charge current is 1A.

Glen,

You are correct, and it is that way on purpose. The charge circuit is intended to be a trickle charge only with a slow charge rate.

This is the way I want it for a couple reasons:

1. These type of batteries typically require a pretty slow charge rate to last very long and to not overheat.

2. In the event that I accidently run this battery all the way down, this resistor becomes the only limiter to the current since the internal resistance of these types of batteries is like .025 ohms. This current limit resistor will keep the battery from overheating and or blowing the charge circuit fuse.

Since most of the time this battery may only get used for a few minutes during startup, most flights it will have plenty of time to stay charged up fully.

Be cautious around EE's, they are strange people!!!

Last edited:

Question:

Will having the alternate battery being recharged any time the master is on shorten the battery life? When we updated my panel we put the alternate battery on a breaker to the avionics bus only. That way I can get the atis info and program the 396 and 430 off the alternate battery without the master being on. After starting the engine I then turn on the avionics master and rechage the alternate battery until I get my first 396 advisory to switch fuel tanks at thirty minutes into the flight. Then I turn off the breaker to the alternate battery until the next flight. It doesn't make sense to me to have the alternate battery controlled by the master breaker and having both batteries discharging at the same time.

Just my 2 cents.

John Morgan

Will having the alternate battery being recharged any time the master is on shorten the battery life? When we updated my panel we put the alternate battery on a breaker to the avionics bus only. That way I can get the atis info and program the 396 and 430 off the alternate battery without the master being on. After starting the engine I then turn on the avionics master and rechage the alternate battery until I get my first 396 advisory to switch fuel tanks at thirty minutes into the flight. Then I turn off the breaker to the alternate battery until the next flight. It doesn't make sense to me to have the alternate battery controlled by the master breaker and having both batteries discharging at the same time.

Just my 2 cents.

John Morgan

Brantel

Well Known Member

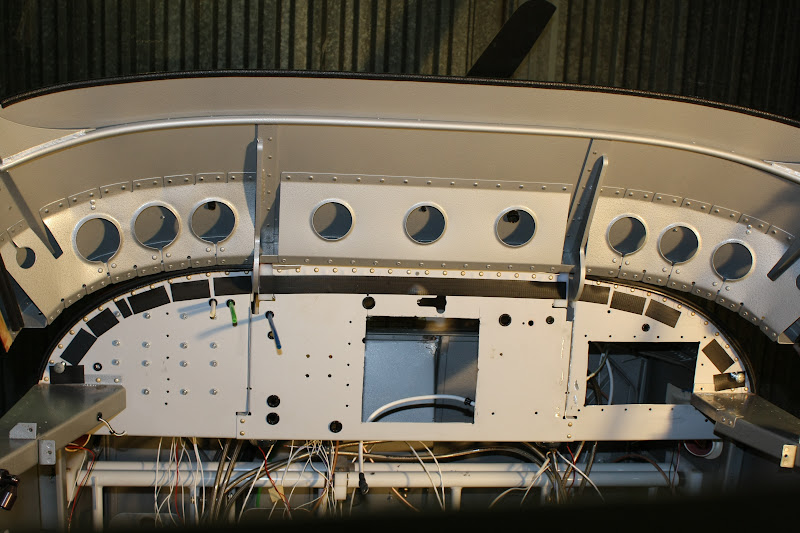

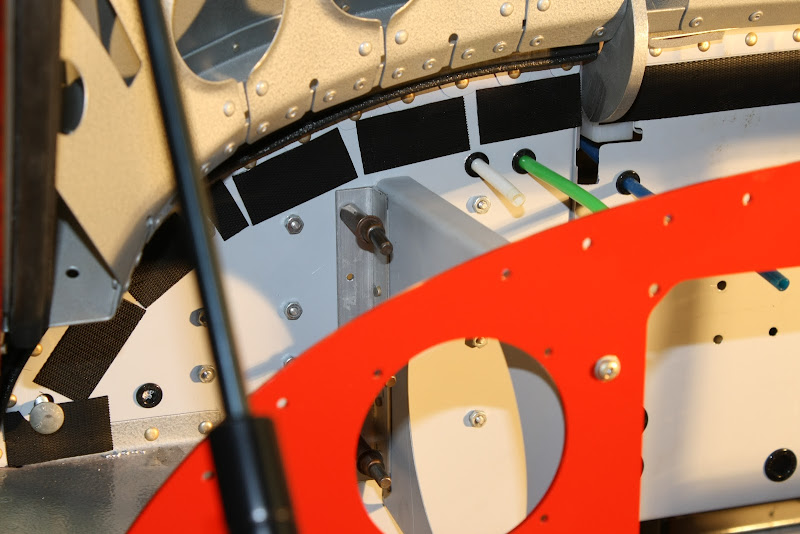

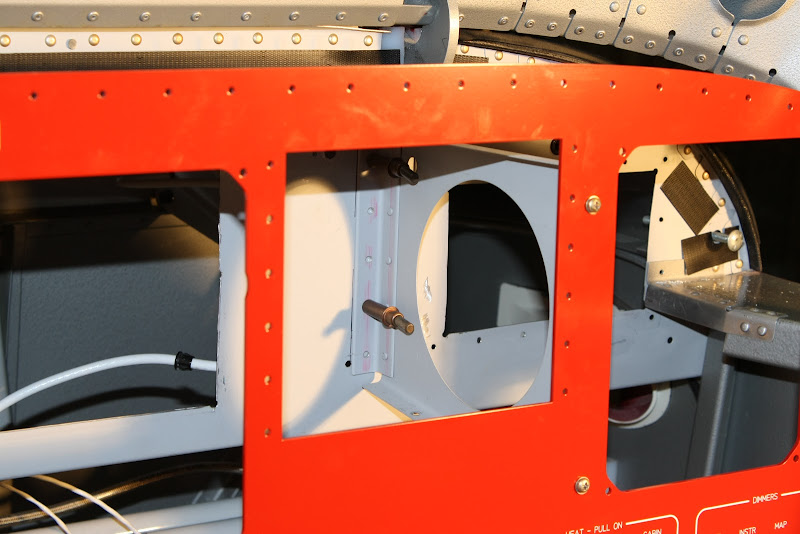

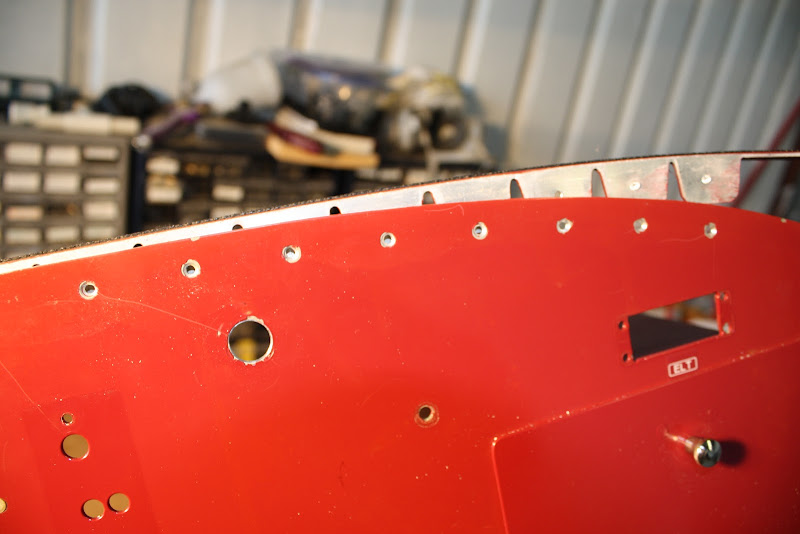

I want to get all the heavy cutting, grinding, drilling, etc. out of the way before the avionics even come out of the box. Then do a good vacum job on the interior to get rid of the mess I have made.

So last night I started working on the panel support ribbs.

The old panel support had three ribs. Two on the pilot side that were riveted in non-standard locations and one factory one on the co-pilot side.

I had to drill out the one on the left and the one on the center and then cut the one off on the right. I also drilled out all the rivets for the old map box braces.

Here it is all clean and full of holes like swiss cheese!

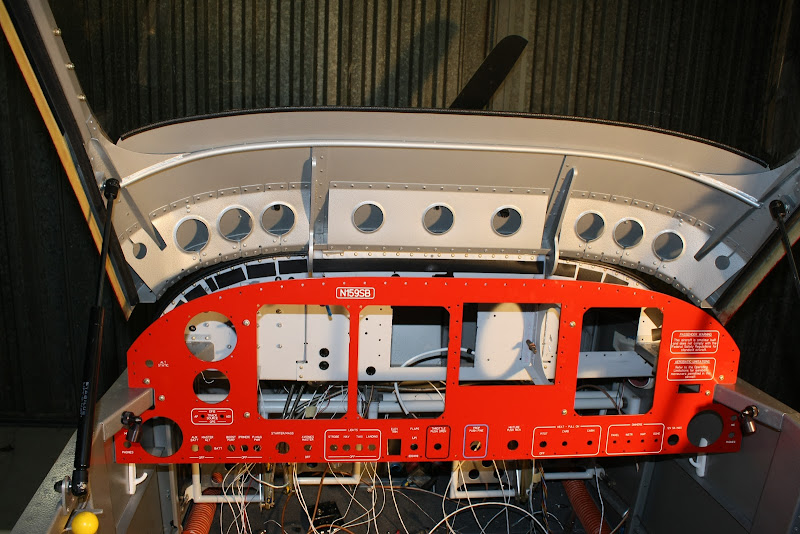

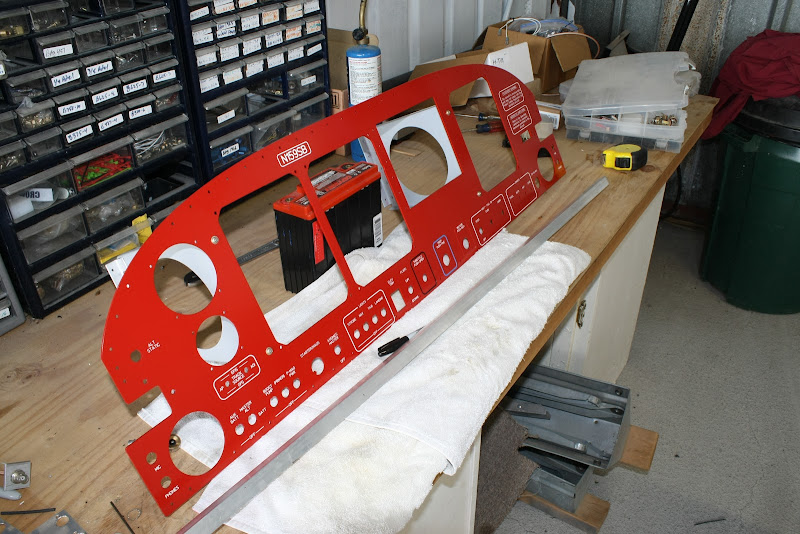

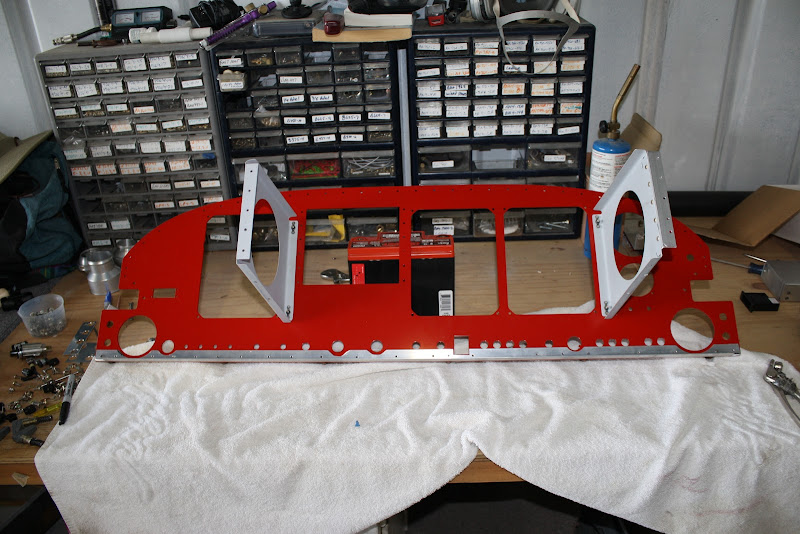

So then I discarded the pilot side one and added a new piece of angle to the one I cut off from the co-pilot side and re-mounted it to the pilot side. I moved the center one to the co-pilot side. The new panel will not have a third one. I used the Red panel to locate and drill the new locations for the ribs. Keep in mind that this Red panel is now a mock-up only panel because I do not like the Red color mismatch with the fuse. I have a new Grey one being built that will become the final panel.

So last night I started working on the panel support ribbs.

The old panel support had three ribs. Two on the pilot side that were riveted in non-standard locations and one factory one on the co-pilot side.

I had to drill out the one on the left and the one on the center and then cut the one off on the right. I also drilled out all the rivets for the old map box braces.

Here it is all clean and full of holes like swiss cheese!

So then I discarded the pilot side one and added a new piece of angle to the one I cut off from the co-pilot side and re-mounted it to the pilot side. I moved the center one to the co-pilot side. The new panel will not have a third one. I used the Red panel to locate and drill the new locations for the ribs. Keep in mind that this Red panel is now a mock-up only panel because I do not like the Red color mismatch with the fuse. I have a new Grey one being built that will become the final panel.

humptybump

Well Known Member

Brian,

One thing I am curious how you solved is the back support for the radio stack. Do you have a direct supporting connection at the back of your radio stack and if so, how is it fastened ?

In my case, I want my panel to be easily removable. The radio stack back "support connection" is what I have not figure out yet.

One thing I am curious how you solved is the back support for the radio stack. Do you have a direct supporting connection at the back of your radio stack and if so, how is it fastened ?

In my case, I want my panel to be easily removable. The radio stack back "support connection" is what I have not figure out yet.

Brantel

Well Known Member

Brian,

One thing I am curious how you solved is the back support for the radio stack. Do you have a direct supporting connection at the back of your radio stack and if so, how is it fastened ?

In my case, I want my panel to be easily removable. The radio stack back "support connection" is what I have not figure out yet.

Not yet but I know what I want to do. I will have an angle fastened to the sub panel horizontally creating a shelf for the trays. I will also make two vertical ones on the sub panel that are removable for the sides and the trays will get a screw thru the side into them.

Brantel

Well Known Member

Question:

Will having the alternate battery being recharged any time the master is on shorten the battery life? When we updated my panel we put the alternate battery on a breaker to the avionics bus only. That way I can get the atis info and program the 396 and 430 off the alternate battery without the master being on. After starting the engine I then turn on the avionics master and rechage the alternate battery until I get my first 396 advisory to switch fuel tanks at thirty minutes into the flight. Then I turn off the breaker to the alternate battery until the next flight. It doesn't make sense to me to have the alternate battery controlled by the master breaker and having both batteries discharging at the same time.

Just my 2 cents.

John Morgan

John,

No it does not and as far as that goes, most UPS's and alarm systems have these types of batteries and while the power is on, they are being charged.

But being charged is kinda bad terminology....current will only flow into the battery when the battery's voltage is less than that of the voltage being applied to it. So if you apply a constant voltage to the battery, it will self regulate it's charge current down to the point where little if any current is flowing as long as the battery is capable of reaching a voltage that is close or equal to the applied voltage.

Such is the case with my planned circuit. The applied voltage when the master is on and the alternator is running will always be one Schottky diode drop below the voltage regulator output or somewhere around 13.8 volts which is right at the top of the recommended float charge voltage of this battery....

There are batteries out there that need constant current charging and that is a completely different animal.

"It doesn't make sense to me to have the alternate battery controlled by the master breaker and having both batteries discharging at the same time."

The reason this does not make sense to you is because that is not the way it all works. The load will only pull current from the supply with the highest voltage because the two power inputs are fed thru two back to back diodes....

The Aux battery is not controlled by the master relay, only charged by it. The Aux battery bus has it's own switch that comes on before start and stays on until shutdown. The Aux battery only provides current to the critical loads during startup until the engine is running with the alternator on and the avionics master is turned on. From that point the critical loads will source their current from their primary feeds thru the VP-X Pro unless the main battery and the alternator dies and in that case, the backup battery will start providing current to the critical loads.

Last edited:

Brantel

Well Known Member

First thing today was cleanup and cleanout time of the cockpit. I pulled up the carpet and cleaned all the wires, connectors, tools, screws, washers, nuts, bolts, parts etc. etc. etc. out of the airplane. It was a complete mess. I got it all cleaned up and moved on to making more of a mess....

First thing today was to remove the canopy. I hate putting it at risk but it just had to be done. My buddy that helped me who is also an RV builder and I both commented on how crazy I was for even messing with the canopy let alone taking it off and laying it in the floor. Hopefully it won't get damaged during the process.

Looks weird but it really opens up the work space. I needed to do some work on the seal in the front. The work I needed to do could not be done with the canopy on there. Bonus is that it is out of my way....

Got out the Dremel and did the cuts of the seal shelf that I needed to do. If I were building another tipup RV, this area would be built very much differently!!!!

Fabricating a new angle to go along the bottom of the panel.

All drilled in place.

Some reliefs need to be cut to make room for components of the panel.

Mark em and provide some relief.

All the reliefs cut out and blended.

Shot from behind....

Drilled out all the rivets holding this angle to the old panel. Not about to remake that thing again!!!

All removed and ready to fit to the new panel.

First thing today was to remove the canopy. I hate putting it at risk but it just had to be done. My buddy that helped me who is also an RV builder and I both commented on how crazy I was for even messing with the canopy let alone taking it off and laying it in the floor. Hopefully it won't get damaged during the process.

Looks weird but it really opens up the work space. I needed to do some work on the seal in the front. The work I needed to do could not be done with the canopy on there. Bonus is that it is out of my way....

Got out the Dremel and did the cuts of the seal shelf that I needed to do. If I were building another tipup RV, this area would be built very much differently!!!!

Fabricating a new angle to go along the bottom of the panel.

All drilled in place.

Some reliefs need to be cut to make room for components of the panel.

Mark em and provide some relief.

All the reliefs cut out and blended.

Shot from behind....

Drilled out all the rivets holding this angle to the old panel. Not about to remake that thing again!!!

All removed and ready to fit to the new panel.

Last edited:

Brantel

Well Known Member

Fit just like the original. I used the factory hole locations on the original so this worked fine for the new panel as well. I also cut the subpanel out where the new trays will be intersecting... I will have to fab up and rivet in some patches to fill the old cutouts.

Remember that this Red panel is only for mockup at this point. The real one will be Grey. I am so glad that I have one to use during construction that I don't have to worry about damaging....

I know the progress seems slow but remember I have a wife and three kids 11, 7 & 3 and a full time job. My airplane is 30 minutes away from the house as well.....

Got home and my new backup battery had arrived from BatteryMart.com.

Those folks always ship fast!!!!

Remember that this Red panel is only for mockup at this point. The real one will be Grey. I am so glad that I have one to use during construction that I don't have to worry about damaging....

I know the progress seems slow but remember I have a wife and three kids 11, 7 & 3 and a full time job. My airplane is 30 minutes away from the house as well.....

Got home and my new backup battery had arrived from BatteryMart.com.

Those folks always ship fast!!!!

Last edited:

Question for you

Brian, I am following your upgrade since I am just getting into my panel. You made the statement that you would build the area different if you were doing another tip up. Can you explain what you would different? I don't know enough yet to know what I would change! Any tips would be appreciated. I can't wait to see your new panel when it is done. Good luck with it.

Brian, I am following your upgrade since I am just getting into my panel. You made the statement that you would build the area different if you were doing another tip up. Can you explain what you would different? I don't know enough yet to know what I would change! Any tips would be appreciated. I can't wait to see your new panel when it is done. Good luck with it.

Brantel

Well Known Member

I would most likely make the top front skin removable for one using screws to attach it.

I would also most likely abandon the current tip up hinge design and build the canopy similar to how the 12 is done. This would take some significant work however.

At a minimum, I would modify the seal shelf. I would not make it three pieces. I would take it all the way across. I would use proseal behind it to fill the gaps made by flutting. I would not position it vertically per the plans, instead I would position it so an edge gripping bulb seal would fit in there without deforming the canopy skin in the front.

http://images1.mcmaster.com/Contents/gfx/small/1120a37p1s.png?ver=29924438

I would use proseal extensively on the assembly of the subpanel filling all the holes where the flange notches are. Basically I would do everything I could to stop water from getting in there!

I would also most likely abandon the current tip up hinge design and build the canopy similar to how the 12 is done. This would take some significant work however.

At a minimum, I would modify the seal shelf. I would not make it three pieces. I would take it all the way across. I would use proseal behind it to fill the gaps made by flutting. I would not position it vertically per the plans, instead I would position it so an edge gripping bulb seal would fit in there without deforming the canopy skin in the front.

http://images1.mcmaster.com/Contents/gfx/small/1120a37p1s.png?ver=29924438

I would use proseal extensively on the assembly of the subpanel filling all the holes where the flange notches are. Basically I would do everything I could to stop water from getting in there!

Last edited:

Brantel

Well Known Member

Short session between Church today....

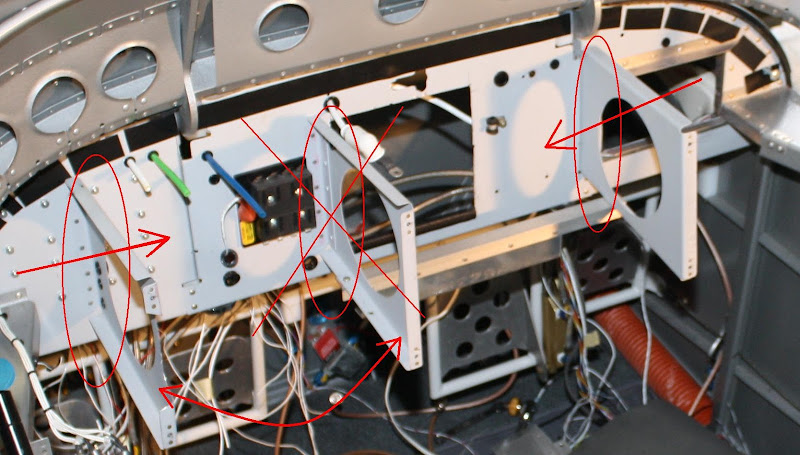

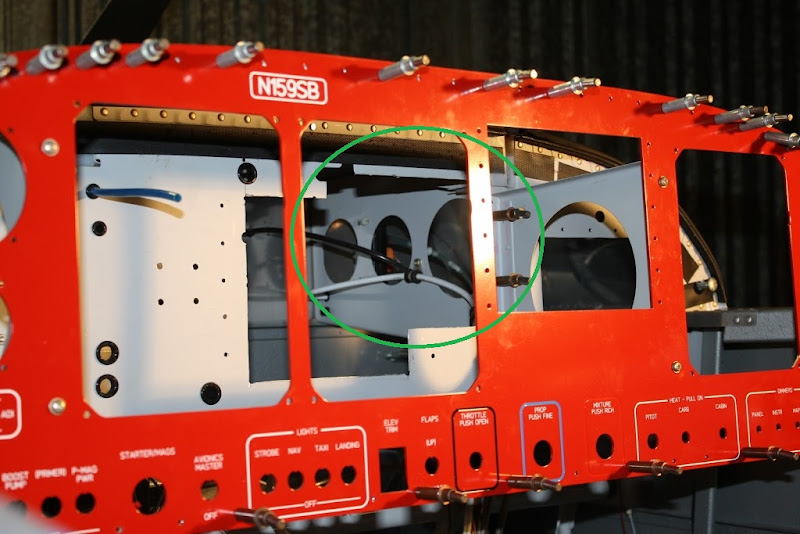

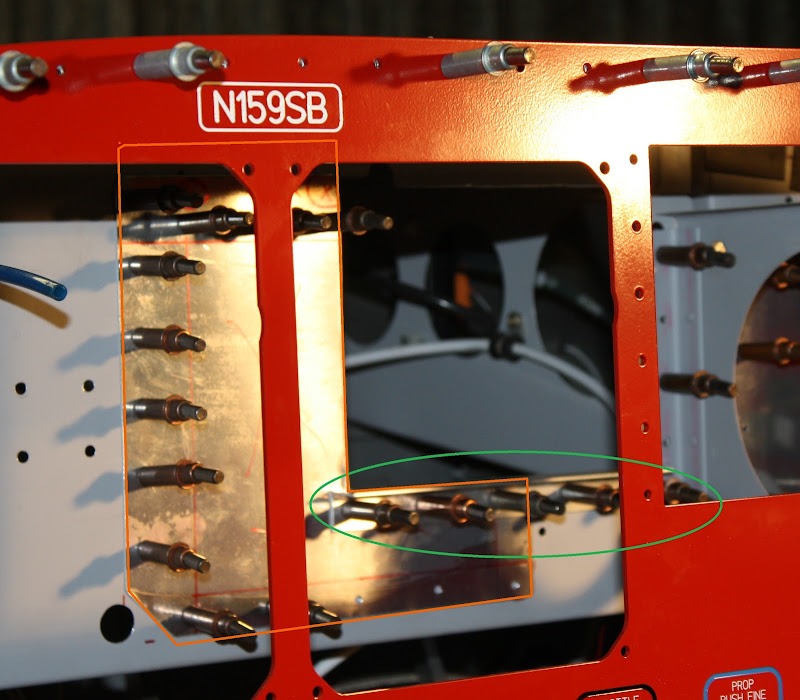

Fabricated and match drilled a new filler piece to cover the old radio stack cut-out in the subpanel. In Orange below. Cut and drilled a new angle shelf for the trays to sit on. In Green below...

Although it does not look like it, there is a new piece filling the hole where the old map box was. Outlined in Green.

Cold and rainy today. Very gloomy!

Avionics arrive tomorrow!!!!!

Fabricated and match drilled a new filler piece to cover the old radio stack cut-out in the subpanel. In Orange below. Cut and drilled a new angle shelf for the trays to sit on. In Green below...

Although it does not look like it, there is a new piece filling the hole where the old map box was. Outlined in Green.

Cold and rainy today. Very gloomy!

Avionics arrive tomorrow!!!!!

Subwaybob

Well Known Member

Go to the hangar. Look at Garmin stuff, rub that bath and body works all over you while eating the Ghirardelli chocolate in your own personal airplane. Eat your heart out world!

Save this link for when you're done:

http://www.youtube.com/watch?v=3GwjfUFyY6M

(Looks great BTW!)

Save this link for when you're done:

http://www.youtube.com/watch?v=3GwjfUFyY6M

(Looks great BTW!)

Jimboscr

Well Known Member

Birthdays

I know how you feel, mine is on the 27th. Did you get the ..."that will do for your Christmas and birthday" line?

However all of the "goodies" you have under the tree look great, hopefully that makes up for all of the "shorted" birthdays. So here is an early Merry Christmas and a Happy Birthday for the 26th.

Jim

Well my birthday is Dec. 26th and all my life I have been sorta shorted in that regard

I know how you feel, mine is on the 27th. Did you get the ..."that will do for your Christmas and birthday" line?

However all of the "goodies" you have under the tree look great, hopefully that makes up for all of the "shorted" birthdays. So here is an early Merry Christmas and a Happy Birthday for the 26th.

Jim

It was the quick change of the label from Christmas to the Happy Birthday label. The number of presents didn't chance just the labelsI know how you feel, mine is on the 27th. Did you get the ..."that will do for your Christmas and birthday" line?

However all of the "goodies" you have under the tree look great, hopefully that makes up for all of the "shorted" birthdays. So here is an early Merry Christmas and a Happy Birthday for the 26th.

Jim

Last edited:

Brantel

Well Known Member

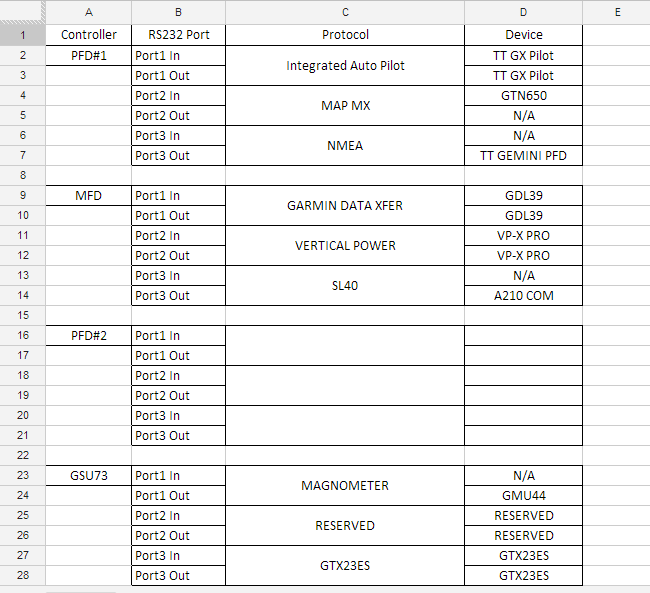

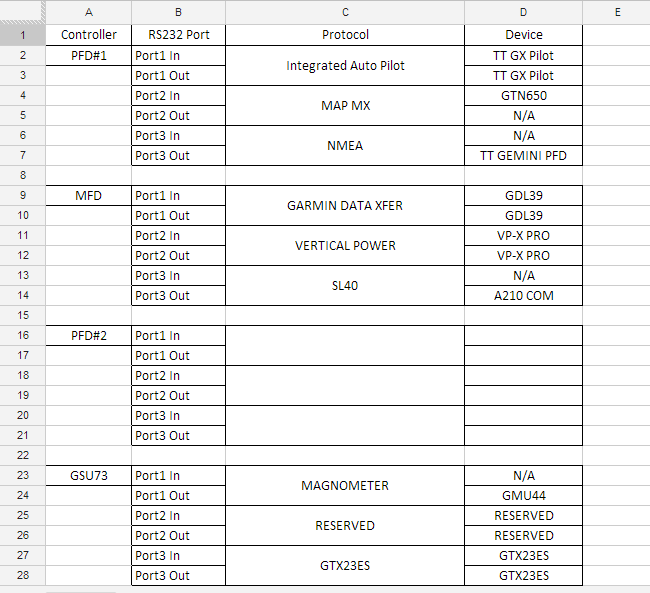

Planning is 80% or more of the work!!!

I feel it is good to have a plan before you start building harnesses. One of the plans you need with a complex integrated system like the G3X is a plan of what serial devices will be connected where and what protocol they will require.

Sometimes you find out there is a surprise waiting for you when you make an assumption and you do not research all of the constraints that may be lurking about....

Its those little notes on the hundreds of pages of documentation that may get you when you least expect it.

Anyway, I sat down with all the manuals and worked my way thru the process of developing an RS232 serial port plan for my new system.

I have already ran this plan by the experts at Garmin and they gave it their blessing with just one suggested change so that ain't bad...

Here it is:

I feel it is good to have a plan before you start building harnesses. One of the plans you need with a complex integrated system like the G3X is a plan of what serial devices will be connected where and what protocol they will require.

Sometimes you find out there is a surprise waiting for you when you make an assumption and you do not research all of the constraints that may be lurking about....

Its those little notes on the hundreds of pages of documentation that may get you when you least expect it.

Anyway, I sat down with all the manuals and worked my way thru the process of developing an RS232 serial port plan for my new system.

I have already ran this plan by the experts at Garmin and they gave it their blessing with just one suggested change so that ain't bad...

Here it is:

Brantel

Well Known Member

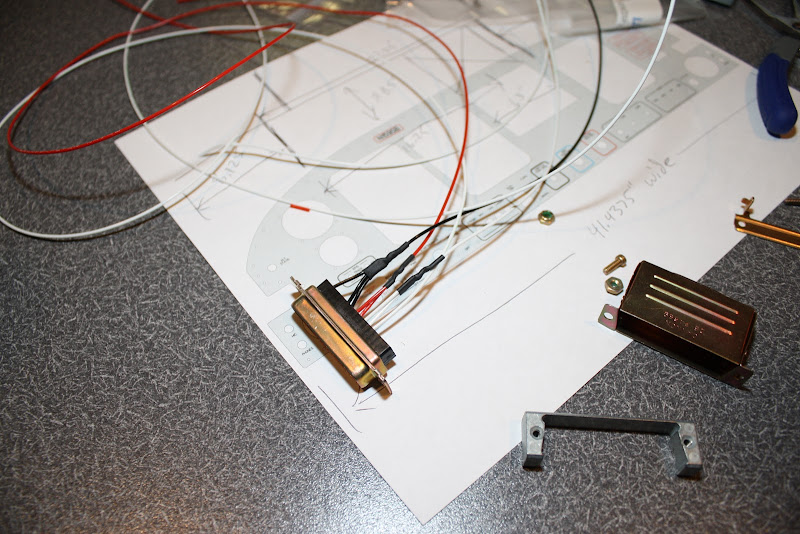

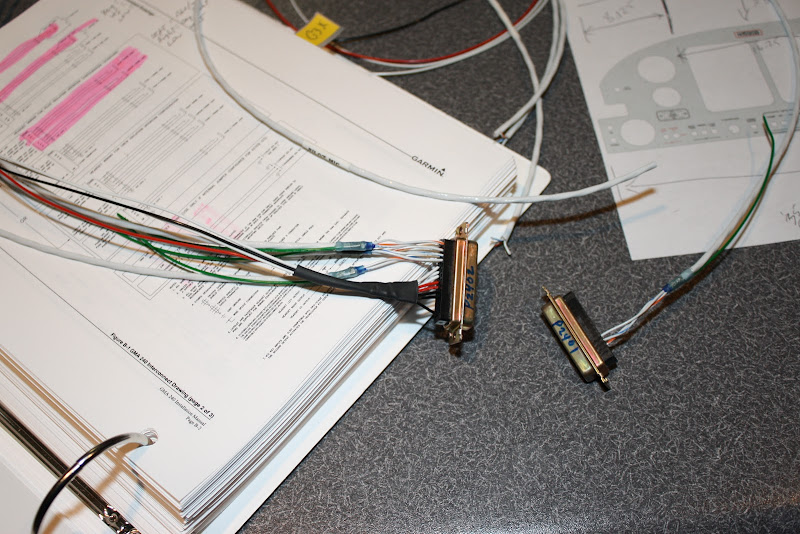

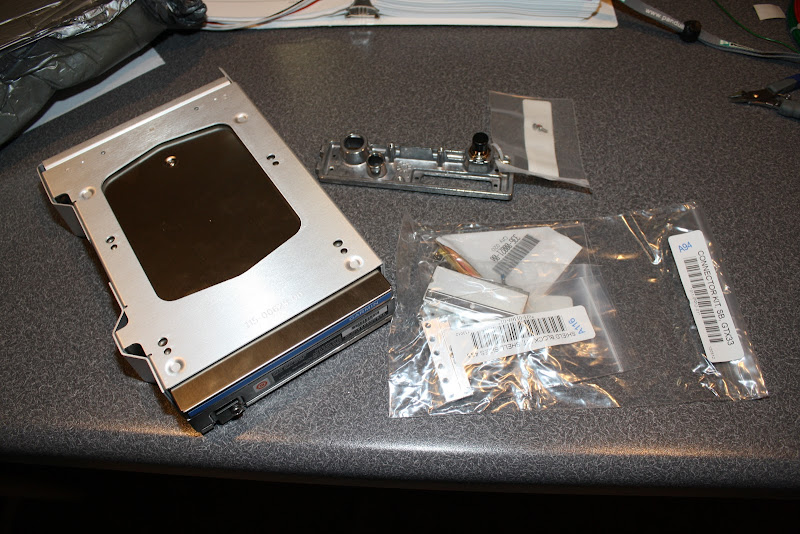

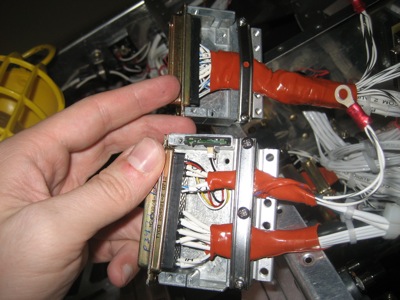

Harness for the GMA240 Audio Panel

Started working on the harness for the GMA240 Audio Panel last night.

GMA240 as you get it in the box:

Whats included:

Started working on the connector with the power connections and option pins. Several pins need spliced connections in order to get all the power and signals in the right places. You must be able to make small inline solder splices for these. I am SO glad that Garmin redesigned these connector backshells. The old style like these are a pain!

First one pretty much done and now on to the second one. Solder sleeves ROCK!

Feeds for all the radio stack and G3X, also shown are the thermal heat shrink labels I am using before shrinking:

First connector complete:

Fruits of my labor. All that is needed to finish this up other than connect to the devices is to crimp on a terminal for the shield terminations (solder sleeves ROCK). I forgot my crimper and terminals at the hangar....

Did I mention SOLDER SLEEVES ROCK? Get em from Stein here.

Started working on the harness for the GMA240 Audio Panel last night.

GMA240 as you get it in the box:

Whats included:

Started working on the connector with the power connections and option pins. Several pins need spliced connections in order to get all the power and signals in the right places. You must be able to make small inline solder splices for these. I am SO glad that Garmin redesigned these connector backshells. The old style like these are a pain!

First one pretty much done and now on to the second one. Solder sleeves ROCK!

Feeds for all the radio stack and G3X, also shown are the thermal heat shrink labels I am using before shrinking:

First connector complete:

Fruits of my labor. All that is needed to finish this up other than connect to the devices is to crimp on a terminal for the shield terminations (solder sleeves ROCK). I forgot my crimper and terminals at the hangar....

Did I mention SOLDER SLEEVES ROCK? Get em from Stein here.

Brantel

Well Known Member

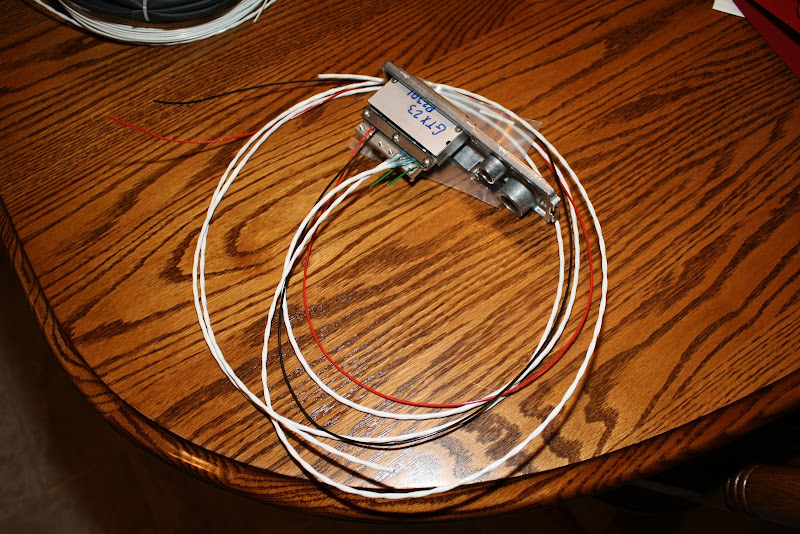

GTX23ES Harness

On to the GTX23ES harness. This unit is remote mounted and totally controlled by the G3X system and here is what comes in the box:

Here is what you get layed out:

Here is my first go at the new type of backshell and the fruits of my labor. I learned a few things on this go round like:

Even though the directions specifically say to allow the shield drain wire to extend toward the connector, this does not work out very well and for the rest of em, I will make em extend away from the connector.

Give myself a little more extra wire sticking out past the solder sleeve for clearance of the clamp...the recommended amount is in the middle of the range and it is not enough.

On to the GTX23ES harness. This unit is remote mounted and totally controlled by the G3X system and here is what comes in the box:

Here is what you get layed out:

Here is my first go at the new type of backshell and the fruits of my labor. I learned a few things on this go round like:

Even though the directions specifically say to allow the shield drain wire to extend toward the connector, this does not work out very well and for the rest of em, I will make em extend away from the connector.

Give myself a little more extra wire sticking out past the solder sleeve for clearance of the clamp...the recommended amount is in the middle of the range and it is not enough.

Even though the directions specifically say to allow the shield drain wire to extend toward the connector, this does not work out very well and for the rest of em, I will make em extend away from the connector.

Give myself a little more extra wire sticking out past the solder sleeve for clearance of the clamp...the recommended amount is in the middle of the range and it is not enough.

Hi Brian,

For what it's worth, I terminate these multi-stranded wires at the connector, I usually like to leave about four fingers' worth of space between the end of the wire and the start of the shield and outer covering. That typically gives me enough room to route the wires to the right pins while still keeping the solder sleeve out of the clamp area. If you have pretty big fingers so you might want to go with three.

As you mentioned, I also typically find it's easier to point the shield ground wire pigtail away from the connector and loop it back around to connect to the terminal block. Seems to work pretty well that way. Silicone fusion tape (sold at the auto store as "rescue tape", or available from the usual aviation places) also works well for protecting the wire bundles where the strain relief clamps grab onto them.

Looks like you are having fun!

mcb

Brantel

Well Known Member

I would like to add a note to all those that may be following this thread and may be considering building their own harnesses.

While this is a very doable task for someone with good electrical skills, it is not trivial. There are hundreds of connections and many places for a screw-up to take place. You must also be able to read the documentation and understand how to integrate all of this stuff together in the right way. There is no step by step direction manual that does this for you, you must do it yourself. It is my understanding that Stein will develop a diagram for you for a reasonable fee and I would recommend that for anyone that is not absolutely sure about their ability to go it alone.

One needs to triple check each and every pin crimp, hole location etc. and then inspect the connector for little whiskers that may be poking out. These can cause major issues down the road if you miss one and it crosses something up. Also be careful to put enough heat shrink on any splices and do not over tighten any of the strain relief clamps. Try and put any splices or shield terminations where they won't be under the clamps.

I highly recommend solder sleeves! Just get about three more times what you think you will need!

Something else to consider is the cost associated with all the materials to make these harnesses is not insignificant. The cost of the wire, heat-shrink, labels, terminals, solder sleeves, shipping etc. all adds up and quick.

It is difficult to estimate the amount of wire and supplies you need and it seems like I am always going to run out of something. Order plenty of extra so you are not stuck waiting on more and having to pay extra shipping on it.

All of this being said, unless you are really into integrating or just want to learn all there is to learn about wiring avionics, I highly recommend that you just order these harnesses pre-made from Stein. I doubt there is much difference in cost by the time you buy all the materials to make em....contact him however for a quote.

While this is a very doable task for someone with good electrical skills, it is not trivial. There are hundreds of connections and many places for a screw-up to take place. You must also be able to read the documentation and understand how to integrate all of this stuff together in the right way. There is no step by step direction manual that does this for you, you must do it yourself. It is my understanding that Stein will develop a diagram for you for a reasonable fee and I would recommend that for anyone that is not absolutely sure about their ability to go it alone.

One needs to triple check each and every pin crimp, hole location etc. and then inspect the connector for little whiskers that may be poking out. These can cause major issues down the road if you miss one and it crosses something up. Also be careful to put enough heat shrink on any splices and do not over tighten any of the strain relief clamps. Try and put any splices or shield terminations where they won't be under the clamps.

I highly recommend solder sleeves! Just get about three more times what you think you will need!

Something else to consider is the cost associated with all the materials to make these harnesses is not insignificant. The cost of the wire, heat-shrink, labels, terminals, solder sleeves, shipping etc. all adds up and quick.

It is difficult to estimate the amount of wire and supplies you need and it seems like I am always going to run out of something. Order plenty of extra so you are not stuck waiting on more and having to pay extra shipping on it.

All of this being said, unless you are really into integrating or just want to learn all there is to learn about wiring avionics, I highly recommend that you just order these harnesses pre-made from Stein. I doubt there is much difference in cost by the time you buy all the materials to make em....contact him however for a quote.

humptybump

Well Known Member

Something else to consider is the cost associated with all the materials to make these harnesses is not insignificant. The cost of the wire, heat-shrink, labels, terminals, solder sleeves, shipping etc. all adds up and quick.

It is difficult to estimate the amount of wire and supplies you need and it seems like I am always going to run out of something. Order plenty of extra so you are not stuck waiting on more and having to pay extra shipping on it.

I am looking forward to doing my own harnesses but I completely agree with the above. I put good odds that I will end up with all tolled there being 25% or more overhead for me - between ordering extras, discovering I didn't need some things, and shipping costs.

When considering the price from Stein or others vs doing the work yourself, one thing that is not obvious is in the "ordering extra" and "pay extra shipping". If you add these into the DIY cost, I am sure the price difference for ordering a harness narrows quickly.

humptybump

Well Known Member

Tony, I'm hoping and praying that I won't be paying that piper!

By he time you get to your panel, I may be suitably equipped to help.

By he time you get to your panel, I may be suitably equipped to help.