Dan Langhout

Well Known Member

1 of 4

Depending on your point of view, this may be a solution looking for a problem. However, in the spirit of sharing ideas and techniques, I submit an "alternate", Alternate Air Door for your consideration .

.

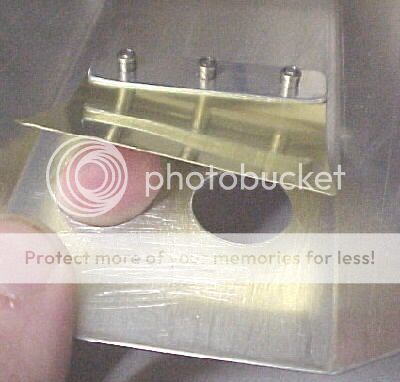

I'm using an IO-375 in my RV-7 with Precision Airmotive injection and horizontal induction. This configuration has the air filter in the left cowl inlet and uses the infamous fiberglass "snorkel" to connect down to the fuel servo. The photo below is the alternate air door that Van's supplies for this application.

It mounts to the outboard side of the snorkel. Now I'm sure that, properly installed, this setup is perfectly adequate for the purpose - hopefully it should never have to be used. However, there has been much discussion in the forums about this design (and other alternate air doors for other configurations) failing over time just due to the vibration environment they live in. I was concerned about this but the thing that bothered me the most about this design though, is the one-way nature of it. I just don't like the thought that there is a control in the cockpit that if operated (even inadvertantly), required the cowling to be removed to reset it. I thought I'd take a shot at an improved design.

My critera was:

- must be able to open AND close using the cockpit control.

- maximum use of composite materials to get away from aluminum fatigue issues.

- no hardware exposed to interior of snorkel (to prevent ingestion hazard in case of failure).

- fit in same spot as Van's door.

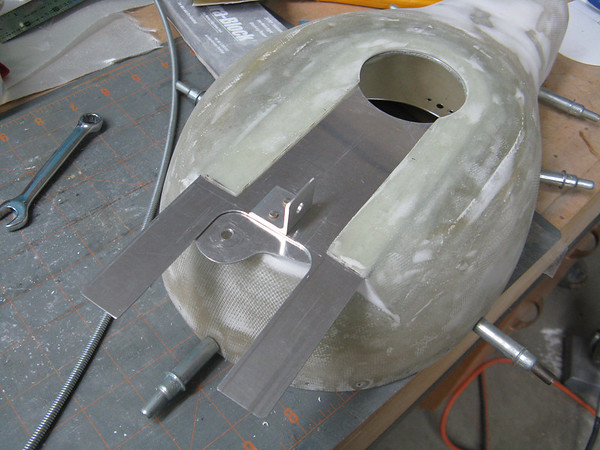

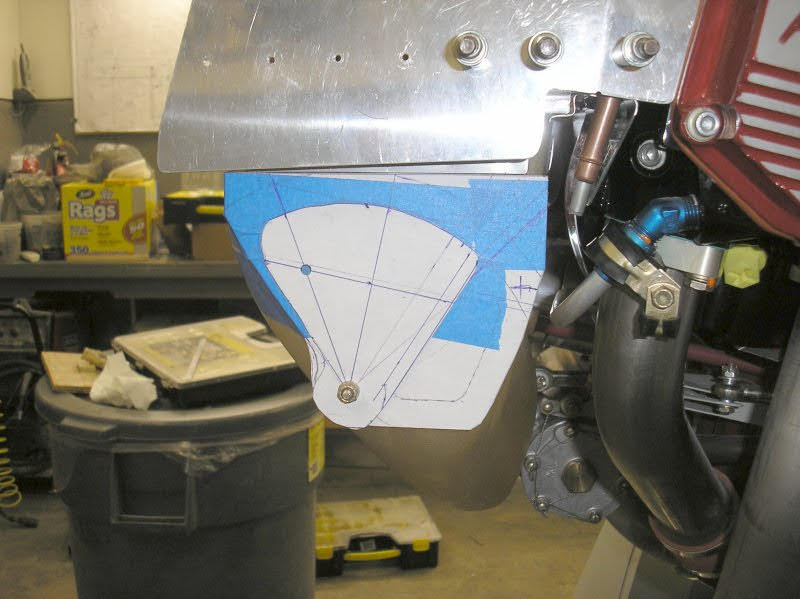

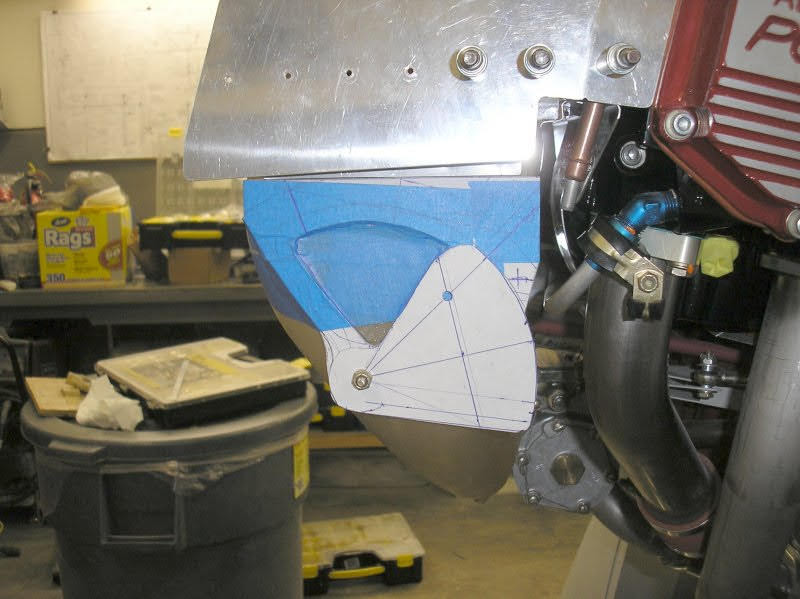

What I came up with was this:

The whole assembly fits within the "sideview" of the snorkel. The pivot bolt does overhang a bit below the area where the snorkel tapers back inboard, but this is by design. There is plenty of clearance to the cowl everywhere. (Note: this might be a bit tighter on an RV-8 cowl - don't know though). The final "V" shaped opening has the same area as the Van's design (~4.4 sq. in.). Key to the design though is that the top of the pivoting door is carried in a "slot" formed into the back plate. This doesn't show on the cardboard template, but stay tuned.

to be continued in part 2 of 4 . . . . . .

Depending on your point of view, this may be a solution looking for a problem. However, in the spirit of sharing ideas and techniques, I submit an "alternate", Alternate Air Door for your consideration

I'm using an IO-375 in my RV-7 with Precision Airmotive injection and horizontal induction. This configuration has the air filter in the left cowl inlet and uses the infamous fiberglass "snorkel" to connect down to the fuel servo. The photo below is the alternate air door that Van's supplies for this application.

It mounts to the outboard side of the snorkel. Now I'm sure that, properly installed, this setup is perfectly adequate for the purpose - hopefully it should never have to be used. However, there has been much discussion in the forums about this design (and other alternate air doors for other configurations) failing over time just due to the vibration environment they live in. I was concerned about this but the thing that bothered me the most about this design though, is the one-way nature of it. I just don't like the thought that there is a control in the cockpit that if operated (even inadvertantly), required the cowling to be removed to reset it. I thought I'd take a shot at an improved design.

My critera was:

- must be able to open AND close using the cockpit control.

- maximum use of composite materials to get away from aluminum fatigue issues.

- no hardware exposed to interior of snorkel (to prevent ingestion hazard in case of failure).

- fit in same spot as Van's door.

What I came up with was this:

The whole assembly fits within the "sideview" of the snorkel. The pivot bolt does overhang a bit below the area where the snorkel tapers back inboard, but this is by design. There is plenty of clearance to the cowl everywhere. (Note: this might be a bit tighter on an RV-8 cowl - don't know though). The final "V" shaped opening has the same area as the Van's design (~4.4 sq. in.). Key to the design though is that the top of the pivoting door is carried in a "slot" formed into the back plate. This doesn't show on the cardboard template, but stay tuned.

to be continued in part 2 of 4 . . . . . .

Last edited: