Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

safety wiring the prop

- Thread starter miyu1975

- Start date

Mike S

Senior Curmudgeon

No photo, sorry.

I used .040" on the prop nuts, however the instructions from MT said to use .032"-------

The 0.40" fit just fine, and from some dark corner of my mind, I seem to remember the FAA likes to see the larger size on a prop.

I figured I could argue the manual against FAA norms, but why bother.

Good luck, tis a pain to get the wire started in some of the positions, I ended up backing off the nut, and inserting the wire prior to re-torquing on a few.

I used .040" on the prop nuts, however the instructions from MT said to use .032"-------

The 0.40" fit just fine, and from some dark corner of my mind, I seem to remember the FAA likes to see the larger size on a prop.

I figured I could argue the manual against FAA norms, but why bother.

Good luck, tis a pain to get the wire started in some of the positions, I ended up backing off the nut, and inserting the wire prior to re-torquing on a few.

I figured I could argue the manual against FAA norms, but why bother.

The inspector MAY require more than the manual recommends.

For example, there are a couple of prop manufacturers that say you don't need to safety at all.

I still require some kind of safety method, whether it be lock nuts, jam nuts, or safety wire.

Constant Speed Prop SW

Ryan,

I do not have any pics of my Safety Wiring but I can give you one hint that will save you much frustration and time. On the CS prop, you will always have a few of the nuts that you will not be able to thread wire through while the nuts are tourqed. Loosen up the nut first, run the wire through, twist the wire then go back and Torque the nuts. A little challenging to guestimate the length but it's the only way. Also, wire them in pairs.

Hope this helps.

Ryan,

I do not have any pics of my Safety Wiring but I can give you one hint that will save you much frustration and time. On the CS prop, you will always have a few of the nuts that you will not be able to thread wire through while the nuts are tourqed. Loosen up the nut first, run the wire through, twist the wire then go back and Torque the nuts. A little challenging to guestimate the length but it's the only way. Also, wire them in pairs.

Hope this helps.

islandmonkey

Well Known Member

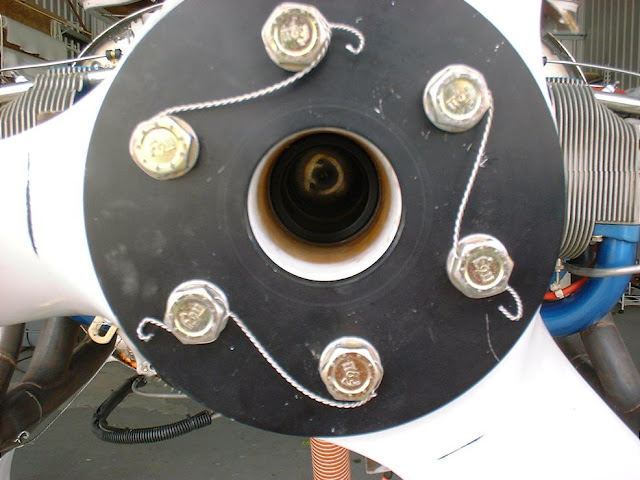

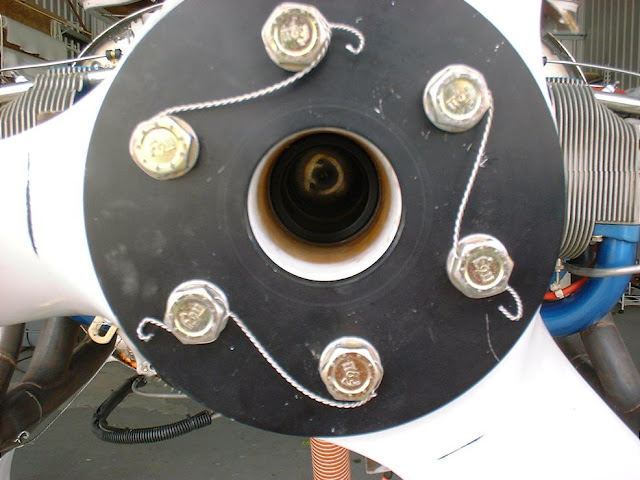

Here is something I googled. It is not an RV. It shows the safety wire preventing the nuts (bolts) from undoing. Hope it helps.

Use 0.040 as Gil suggests.

Also here is a link to Experimenter Magazine with some good advice on safetying:

Use 0.040 as Gil suggests.

Also here is a link to Experimenter Magazine with some good advice on safetying:

Last edited:

flyingriki

Well Known Member

Look awfully loose to me. The bolts can turn ccw quite a bit before the wire does any good. The run between one bolt or nut and the next should be as tight as you can get it.

REALLY LOOSE!

RV6AussieNick

Well Known Member

lock wire

I'm sorry to say but that lock wire won't pass, it's way too loose and twisted too many times, your tails should be turned back on itself so you don't end up with a nasty puncture wound. That's my opinion, I'm sure others will say different.

Cheers,

I'm sorry to say but that lock wire won't pass, it's way too loose and twisted too many times, your tails should be turned back on itself so you don't end up with a nasty puncture wound. That's my opinion, I'm sure others will say different.

Cheers,

David Paule

Well Known Member

Nope, you nailed it.

Dave

Dave

Rick6a

Well Known Member

Sorry, I don't have a picture of the prop bolt nuts on the Hartzell. At the time, I did not realize those nuts are supposed to be safetied and only did that after finding out. I do remember they were a major pain to access and I wired them in pairs. Here is a view of the front of the Hartzell prop where access is far easier. Even so, with little talent for deftly manipulating safety wire pliers like the pros do, using .40, this is the result of my effort after at least six failed attempts.Does any one have a good photo of their safety wired prop. This is on my to do list and I am wanting to make sure I do it correctly. Also, what gauge wire is recommended for this..thanks in advance.

GLPalinkas

Well Known Member

Sensenich Prop Safety Wired

Here is a photo of my Sensenich prop safety wired using .040.

Here is a photo of my Sensenich prop safety wired using .040.

AlexPeterson

Well Known Member

C/S prop

I'll be impressed with anyone who can finish a C/S prop mounting bolt safety wiring session and use only three pieces of wire! I usually have a fairly large pile of scrap wire chunks by the time I'm done. I use .032 for the prop.

I'll be impressed with anyone who can finish a C/S prop mounting bolt safety wiring session and use only three pieces of wire! I usually have a fairly large pile of scrap wire chunks by the time I'm done. I use .032 for the prop.

Look awfully loose to me. The bolts can turn ccw quite a bit before the wire does any good. The run between one bolt or nut and the next should be as tight as you can get it.

+1. Craig Catto has a good write up on this. He suggests very tight safety wire on his props (tight like guitar strings - he even suggests twanging them and listening) It only takes a few degrees of loosening to allow fretting between the prop and hub, which produce high heat and very fast wear. For most uses of safety wire, those would be fine, but not for the prop bolts on an FP.

Larry

Last edited:

My suggestion or at least what I did that I think worked out well for the man prop bolt as they are harder to reach. Torque all the bolts to the spec and check to see which pairs line up well for the safety wire, mark them. Then you can start the wiring if they are lining up well or at least those that do line up. Then you can back out those that don't just to get the wire thru the hole and then re-torque to the specified value.