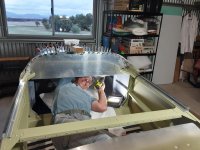

I can grin in this picture because I am taking a break from working on the canopy frame.

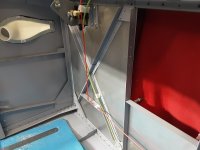

I previously posted about the sliding canopy frame and how it was rusted under the powder coat, so I stripped it back to bare metal and repainted it. When I started fitting the frame to the fuselage it was twisted and welded out of alignment and required bending to improve the fit. As a result of that, it will need to be painted again. The fit is not yet quite right so I will wait until the plexi has been fitted before applying the final finish.

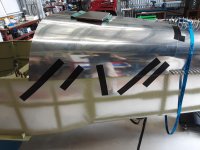

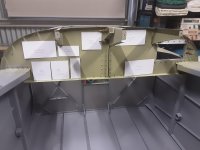

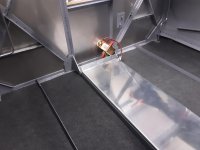

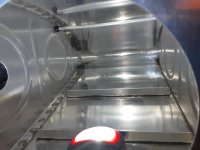

The fwd top skin is the only remaining skin to fit and I again used the method from Gil Alexander on VAF to pilot drill the skeleton 1/16" for all the rivets, fit the skin, back drill the skin 1/16" from underneath, then final drill #40 and cleco from the outside. This method ensures correct placement of rivets through all layers, but it is time consuming. I had installed the cockpit floor first before fitting the top skin, so as to keep everything rigid. It was a 2 person job with my wife sitting on the spar web with a bucking bar and me laying underneath on my back with the rivet gun pointing up. Sounds kinda kinky.

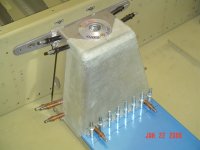

The top skin fit quite well after I got it rolled at a local sheet metal shop. Otherwise, the .032 skin is too rigid to pull into position for a good fit. The sheet metal shop does TIG welding and they were able to put the reinforcing gussets on the external steps in between building custom motorcycles.

I'm trying to keep building along steadily so as to be able to cut and work on the canopy bubble before the winter weather arrives.