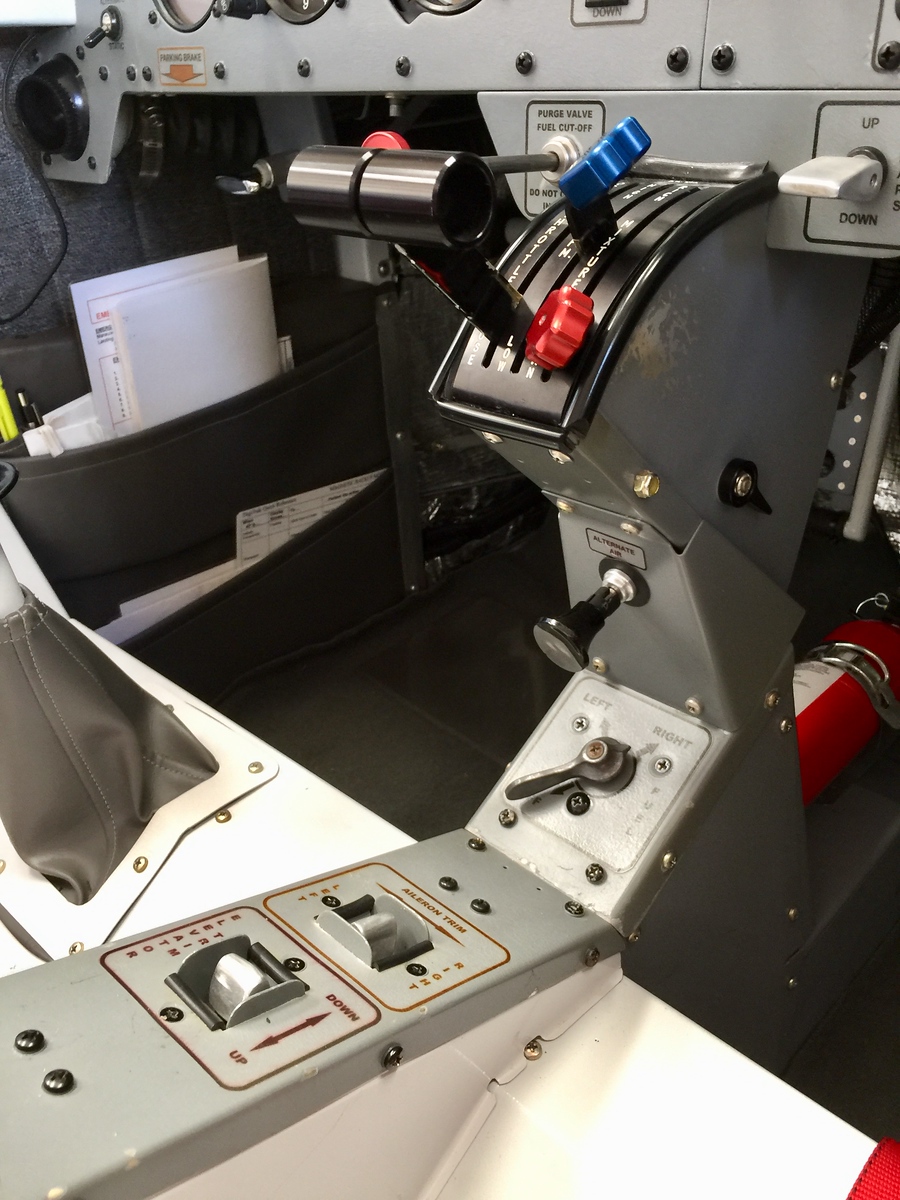

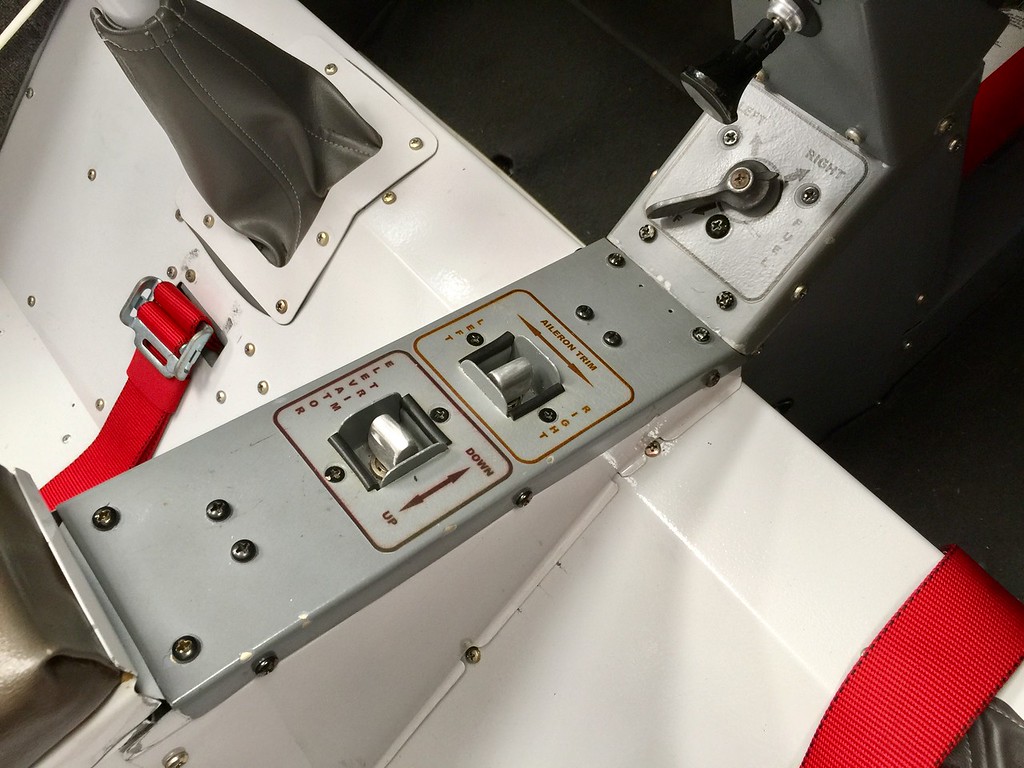

This is the current state of my instrument panel; it's changed several times since I first built N164BL. Like Gene's panel, this started out as a fiberglass panel blank from Laird Owens (thanks Laird - it was super well thought out and manufactured!); I cut the aluminum inserts on my mill and after doing a number of them feel like I could do it almost blindfolded at this point

The flight instrument section has a Skyview system along with a MGL ASI/Altimeter and TrueTrak T&B standbys. Also present is a TAWS annunciator, which is wired to the IFD540. The annunciators are crazy expensive new, but 28v units can be found on eBay for as little as $40. Cut a trace here, jumper a trace there, and now it's a 14v unit

The radio stack has a King audio panel, an Avidyne IFD540, and an ICOM A200 secondary comm. The IFD540 is the most recent addition, and has a couple of things not shown in the panel. I modified the software and image of a Stratux box and built a custom enclosure for it; this allows it to be tucked behind the panel and feed weather/traffic data to the IFD540 and not be subject to image corruption when the avionics master is turned off thanks to a read-only filesystem. It also supports more of the GDL90 standard and excludes some of the stratus-specific stuff that neither the IFD540 or FF appear to use.

The engine stack has a Dynon EMS-D10, which I find I prefer to the Skyview's EMS for a couple of reasons. The PS Engineering PM3000 intercom is there as well along with the ELT switches. I built a Bluetooth 4.0 receiver and mounted it behind this panel as well; wired to both the audio panel and intercom it provides the usual music and phone capability. There are some other custom electronics behind that panel that I'll write up separately as well.

The air vent eyeballs are from Stein and work awesome - no leaks and very smooth operation. The cigarette lighter plug is connected to the hot bus and can be used to charge a cell phone, or can be used to provide ground power for running the avionics with an adapter cable I made (try that with a USB jack!). Speaking of USB, not in view but underneath the panel just to the right of the engine controls are USB jacks and serial lines to both the IFD 540 and Dynon system. This allows me to charge stuff in flight but not have a USB jack take up panel space, while the serial ports facilitate development projects or portable stuff to exchange data with the panel mounted equipment.

There are no circuit breakers - all the switches are toggle switches from B&C. Circuit protection is fuses across three buses: main, avionics, and hot/battery.

Not sure what's next for this panel, but the modular design makes updates really easy and I love the aesthetics of it. I don't think I'd change anything if I was going to do it over again.

[/URL[URL=https://s942.photobucket.com/user/moro17/media/IMG_0051_zpsxu1e0nyc.jpeg.html]

[/URL[URL=https://s942.photobucket.com/user/moro17/media/IMG_0051_zpsxu1e0nyc.jpeg.html] [/URL<a href="https://s942.photobucket.com/user/moro17/media/IMG_0027_zpsgmefdk8e.jpeg.html" target="_blank"><img src="https://i942.photobucket.com/albums/ad264/moro17/IMG_0027_zpsgmefdk8e.jpeg" border="0" alt=" photo IMG_0027_zpsgmefdk8e.jpeg"/></a[URL=https://s942.photobucket.com/user/moro17/media/IMG_0940_zpsdsunvqyw.jpeg.html]

[/URL<a href="https://s942.photobucket.com/user/moro17/media/IMG_0027_zpsgmefdk8e.jpeg.html" target="_blank"><img src="https://i942.photobucket.com/albums/ad264/moro17/IMG_0027_zpsgmefdk8e.jpeg" border="0" alt=" photo IMG_0027_zpsgmefdk8e.jpeg"/></a[URL=https://s942.photobucket.com/user/moro17/media/IMG_0940_zpsdsunvqyw.jpeg.html] [/URL[URL=http://s942.photobucket.com/user/moro17/media/IMG_0938_zpsxl0fjpfx.jpeg.html]

[/URL[URL=http://s942.photobucket.com/user/moro17/media/IMG_0938_zpsxl0fjpfx.jpeg.html] [/URL[URL=http://s942.photobucket.com/user/moro17/media/IMG_0937_zpsbi1htnah.jpeg.html]

[/URL[URL=http://s942.photobucket.com/user/moro17/media/IMG_0937_zpsbi1htnah.jpeg.html] [/URL[URL=https://s942.photobucket.com/user/moro17/media/IMG_0942_zpswvemqd2e.jpeg.html]

[/URL[URL=https://s942.photobucket.com/user/moro17/media/IMG_0942_zpswvemqd2e.jpeg.html] [/URL[URL=https://s942.photobucket.com/user/moro17/media/IMG_1404_zpsmjwudvq0.jpeg.html]

[/URL[URL=https://s942.photobucket.com/user/moro17/media/IMG_1404_zpsmjwudvq0.jpeg.html]