Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An Unforeseen Journey

- Thread starter Bill Boyd

- Start date

ppilotmike

Well Known Member

Sure would like to visit your strip in my 10 one day. Your build is coming together nicely, Bill.

Bill Boyd

Well Known Member

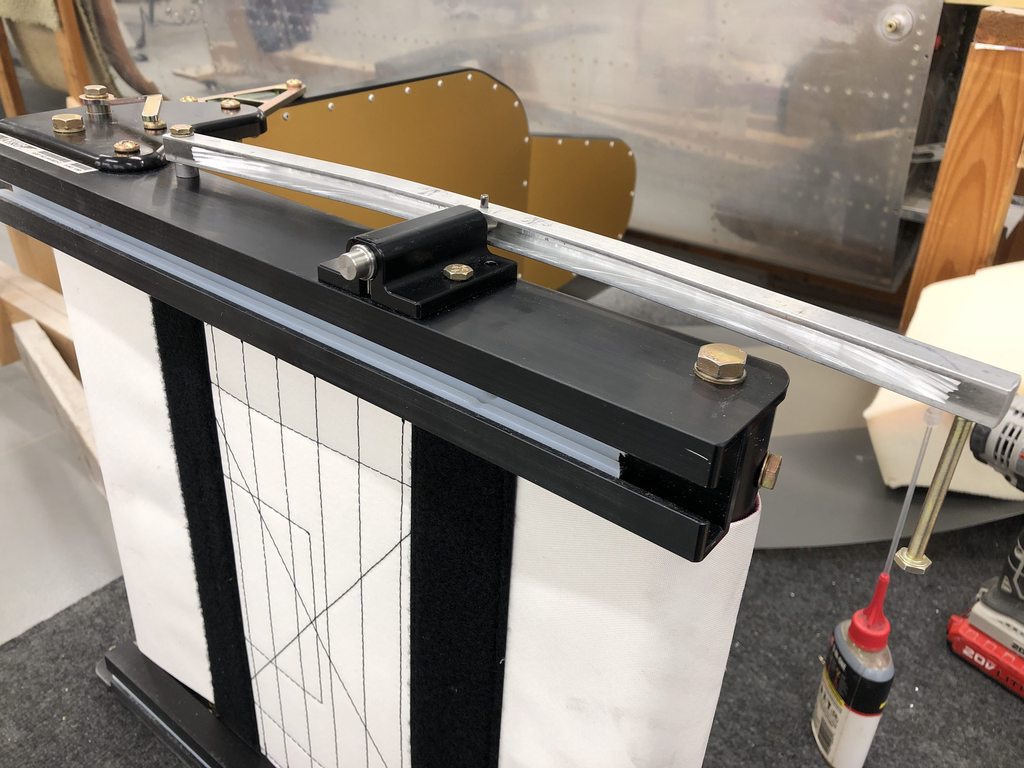

moving on with door work

I got the doors glued up last week and I'm ready to attempt the installation of the factory locking hardware and Sean's excellently-made PlaneAround center latch kit.

The first time you lift those DeLorean gull-wing doors on their own hinges cannot help but bring a smile, and a selfie :

At this point I think I'm supposed to proceed by installing the latch handle/factory gearbox per plans and then (having cut the rack gears exactly in half and modified the aft pushrod length), install the goodies Sean puts in the kit for the center latch. We'll see. Following two set of directions at once is mentally stretching late at night.

I got the doors glued up last week and I'm ready to attempt the installation of the factory locking hardware and Sean's excellently-made PlaneAround center latch kit.

The first time you lift those DeLorean gull-wing doors on their own hinges cannot help but bring a smile, and a selfie :

At this point I think I'm supposed to proceed by installing the latch handle/factory gearbox per plans and then (having cut the rack gears exactly in half and modified the aft pushrod length), install the goodies Sean puts in the kit for the center latch. We'll see. Following two set of directions at once is mentally stretching late at night.

Bill Boyd

Well Known Member

late summer progress

Got the overhead console out of LeoK's mold and fitted in, more or less.

Some trimming required, naturally.

Making a cable chase plenum in the A-pillars: Bondo some 3/4" PEX in place and cover with tape and release agent.

After the 3-ply layups cure, rip out the male mold elements and sand the Bondo off

Trim the layups and glue in place with flox...

Next is a micro skim coat and lots of sanding to fair them in.

I'll attach the overhead itself once I've glued the copper foil Vee antenna for VOR/LOC/GS and the comm #2 vertical to the inside of the canopy top and run some wires that I'd rather do while I have full open exposure to the route. Transitions from the plenums to the overhead and to each side of the fuselage/instrument panel will need to be laid up in roughly the same way. Then I get to try CanadianJOY's faux Zolatone paint process to hide all the blems and give me a rugged finish on the top and door interiors

Got the overhead console out of LeoK's mold and fitted in, more or less.

Some trimming required, naturally.

Making a cable chase plenum in the A-pillars: Bondo some 3/4" PEX in place and cover with tape and release agent.

After the 3-ply layups cure, rip out the male mold elements and sand the Bondo off

Trim the layups and glue in place with flox...

Next is a micro skim coat and lots of sanding to fair them in.

I'll attach the overhead itself once I've glued the copper foil Vee antenna for VOR/LOC/GS and the comm #2 vertical to the inside of the canopy top and run some wires that I'd rather do while I have full open exposure to the route. Transitions from the plenums to the overhead and to each side of the fuselage/instrument panel will need to be laid up in roughly the same way. Then I get to try CanadianJOY's faux Zolatone paint process to hide all the blems and give me a rugged finish on the top and door interiors

Looks good Bill. Happy it worked out for you.

I just finished bonding the A pillar close outs in myself not too long ago. I am interested in a little more detail on the copper tape antennas you bonded in. I plan on the VOR in the wing tip and have two comm antennas out the bottom under the front of the baggage compartment.

I just finished bonding the A pillar close outs in myself not too long ago. I am interested in a little more detail on the copper tape antennas you bonded in. I plan on the VOR in the wing tip and have two comm antennas out the bottom under the front of the baggage compartment.

Bob Martin

Well Known Member

Dust

Stormy,

Work looks good.

Shop looks nice too...

but the garage door is to take that dusty stuff outside in this nice fall weather for sanding etc.....

We can see the half hearted attemp at floor cleaning with a push broom.

Stormy,

Work looks good.

Shop looks nice too...

but the garage door is to take that dusty stuff outside in this nice fall weather for sanding etc.....

We can see the half hearted attemp at floor cleaning with a push broom.

Bill Boyd

Well Known Member

Bob, you should see...

the dusty stuff I sometimes track upstairs from the basement to the first floor and onto the dark laminate flooring. And you should hear the words that come out of my wife's mouth when she sees what I've done (again). I am constantly chagrinned that a whole flight of carpeted steps is not sufficient to clean the soles of my tennis shoes when I forget to wipe them on the mat before exiting the shop.

Yes, I could sand outside, but don't see the point now that the dust from earlier sessions has gone everywhere in the shop and the plane. I plan to continue my halfhearted sweeping efforts and will do a big deep-clean when the sanding phase is over (is it ever?)

I am bach-ing it this weekend and plan to do a lot of work while she's away, but was telling myself tonight - this is going to take a LOT of coats and dabs of micro to get it the way I want it, together with HOURS of sanding said micro. Add in epoxy cure time and it's plain I won't get far on a given "airplane weekend."

I can't get the overhead glued in until the VOR antenna is laid out and overcoated with neat epoxy for protection. The antenna foil can't go down until the B-pillars are contoured and smoothed - which leads me back to the micro coating and sanding mentioned above. At least I got the 108 MHz coaxial balun made up tonight.

One bite of the elephant at a time.

the dusty stuff I sometimes track upstairs from the basement to the first floor and onto the dark laminate flooring. And you should hear the words that come out of my wife's mouth when she sees what I've done (again). I am constantly chagrinned that a whole flight of carpeted steps is not sufficient to clean the soles of my tennis shoes when I forget to wipe them on the mat before exiting the shop.

Yes, I could sand outside, but don't see the point now that the dust from earlier sessions has gone everywhere in the shop and the plane. I plan to continue my halfhearted sweeping efforts and will do a big deep-clean when the sanding phase is over (is it ever?)

I am bach-ing it this weekend and plan to do a lot of work while she's away, but was telling myself tonight - this is going to take a LOT of coats and dabs of micro to get it the way I want it, together with HOURS of sanding said micro. Add in epoxy cure time and it's plain I won't get far on a given "airplane weekend."

I can't get the overhead glued in until the VOR antenna is laid out and overcoated with neat epoxy for protection. The antenna foil can't go down until the B-pillars are contoured and smoothed - which leads me back to the micro coating and sanding mentioned above. At least I got the 108 MHz coaxial balun made up tonight.

One bite of the elephant at a time.

Kyle Boatright

Well Known Member

<snip>...

I can't get the overhead glued in until the VOR antenna is laid out and overcoated with neat epoxy for protection. The antenna foil can't go down until the B-pillars are contoured and smoothed - which leads me back to the micro coating and sanding mentioned above. At least I got the 108 MHz coaxial balun made up tonight.

One bite of the elephant at a time.

The precedence relationships for finishing the cabin top, doors, and windows are worse than those in the Manhattan project. You can't finalize the door gaps until the cabin top is done. You can't do the cabin top fiberglass until the windows are in. You can't put all of the windows in until the upper front fuselage is in. You don't want to install the upper front fuselage before the panel and sub-panel are mostly complete. Also, you don't want all of your wiring and panel goodies to get covered in an inch of sanding dust.

It almost turns into an infinite loop. So you just have to pick a point in the loop (mobius strip?) and go from there, knowing that your actions will increase the level of skill/difficulty/patience required on some other part of the build. It is maddening, and then you throw in the complicating factors of paint and epoxy curing times, the time, space, and conditions you need to do a decent job of painting all of the interior bits, and those sections in the manual take forever. I look longingly back at the days of "Tab A into Slot B" building...

Bob Martin

Well Known Member

Problem solved

Stormy,

I found your problem.......

"dark laminate flooring"

Switch to a fiberglass dust colored flooring!!

Stormy,

I found your problem.......

"dark laminate flooring"

Switch to a fiberglass dust colored flooring!!

Bill Boyd

Well Known Member

Bob - great idea! I will check the Moduleo laminate catalog right now and see what the offerings are in "Pink dust with white speckles."

Meanwhile, Kyle hit it spot on in his analysis. Anyone who builds more than a barebones -10 with spartan interior knows well what he refers to. That comment should exist in the -10 forum as a "sticky" unto itself.

Kyle, I might take one exception to your topographic mapping of the Mobius strip: I believe (and hope to act thereon) that one can finish the exterior fiberglass ready for paint before installing the windows. But for the windshield, this could be done 100% ahead of time. Because the windshield to forward skin transition requires an extensive in-place fiberglass layup, the evil forces you detailed come into play, but only in the front lower corners of the fiberglass top.

I guess I'll find out. FWIW I'm planning to use the YouTube GlasStar window technique others have linked to before. (At 10:05, he mentions the primer already on the cabin top as he's rough-fitting the transparency)

https://www.youtube.com/watch?v=A336SG-fsiI

Meanwhile, Kyle hit it spot on in his analysis. Anyone who builds more than a barebones -10 with spartan interior knows well what he refers to. That comment should exist in the -10 forum as a "sticky" unto itself.

Kyle, I might take one exception to your topographic mapping of the Mobius strip: I believe (and hope to act thereon) that one can finish the exterior fiberglass ready for paint before installing the windows. But for the windshield, this could be done 100% ahead of time. Because the windshield to forward skin transition requires an extensive in-place fiberglass layup, the evil forces you detailed come into play, but only in the front lower corners of the fiberglass top.

I guess I'll find out. FWIW I'm planning to use the YouTube GlasStar window technique others have linked to before. (At 10:05, he mentions the primer already on the cabin top as he's rough-fitting the transparency)

https://www.youtube.com/watch?v=A336SG-fsiI

Last edited:

Bill Boyd

Well Known Member

Progress update

After months of work, I can stand back and look at the top and doors and realize that one of the scariest parts of the build is behind me. The glass parts have been trimmed and fashioned into two well-fitting doors, the overhead console has been fabricated and installed, copper foil antennas epoxied in, and the interior "fake Zolatone" applied with good results.

If I had appreciated beforehand how much this treatment was going to hide blemishes and imperfections in the substrate, I'd have skipped most of several weeks' worth of micro skim coats and sanding to address pinholes and waviness! Oh, well. Good practice for the exterior 'glass.

The process was copied from Mark, a.k.a. Canadian Joy. It consists of semigloss (in my case) latex interior paint rolled on - two coats with wet sanding between, then Krylon stone finish spray paint fogged on with quick passes from 2-3 feet away, then a matte clear spray paint to lock it all down and hopefully keep the bumpy finish particles from chipping off. The masking tape is there to provide a flat mating surface for the McMaster bulb seals and beneath the contrasting color window trim to be sprayed on later.

Yesterday while I was at work and the workpiece was at home in the shop, I torture-tested it by letting it fall off the bench. Apparently the Gorilla Tape used to secure the doors in the closed position for painting decided to let go, a door dropped open and rolled the entire thing off the bench onto the floor.

A panicked inspection revealed nary a crack, ding or scratch anywhere No need for CPR on me, or advanced trauma life support on the cabin structure. I was particularly impressed that the hinge screws didn't tear out since I had only quick-installed one of the 4 screws in each door hinge.

No need for CPR on me, or advanced trauma life support on the cabin structure. I was particularly impressed that the hinge screws didn't tear out since I had only quick-installed one of the 4 screws in each door hinge.

Now I can stroke my whiskers and contemplate the next steps going forward. There remains plenty of steps that are easier to do before the top is in the way permanently. I have a list started, beginning with things that don't require additional big-ticket purchases. It's real estate and personal property tax season in Virginia

After months of work, I can stand back and look at the top and doors and realize that one of the scariest parts of the build is behind me. The glass parts have been trimmed and fashioned into two well-fitting doors, the overhead console has been fabricated and installed, copper foil antennas epoxied in, and the interior "fake Zolatone" applied with good results.

If I had appreciated beforehand how much this treatment was going to hide blemishes and imperfections in the substrate, I'd have skipped most of several weeks' worth of micro skim coats and sanding to address pinholes and waviness! Oh, well. Good practice for the exterior 'glass.

The process was copied from Mark, a.k.a. Canadian Joy. It consists of semigloss (in my case) latex interior paint rolled on - two coats with wet sanding between, then Krylon stone finish spray paint fogged on with quick passes from 2-3 feet away, then a matte clear spray paint to lock it all down and hopefully keep the bumpy finish particles from chipping off. The masking tape is there to provide a flat mating surface for the McMaster bulb seals and beneath the contrasting color window trim to be sprayed on later.

Yesterday while I was at work and the workpiece was at home in the shop, I torture-tested it by letting it fall off the bench. Apparently the Gorilla Tape used to secure the doors in the closed position for painting decided to let go, a door dropped open and rolled the entire thing off the bench onto the floor.

A panicked inspection revealed nary a crack, ding or scratch anywhere

Now I can stroke my whiskers and contemplate the next steps going forward. There remains plenty of steps that are easier to do before the top is in the way permanently. I have a list started, beginning with things that don't require additional big-ticket purchases. It's real estate and personal property tax season in Virginia

Guy Prevost

Well Known Member

I think you will like living with your solution. The interior of my RV-10 is finished with gray Rustoleum stone by itself. I wouldn't have chosen it had I built the airplane, but I would now. I love it. It's light, durable, and hides dirt and imperfections. If only I could figure out a way to make placards (like my experimental placard) stick to it directly, I would be totally satisfied.

Bob Martin

Well Known Member

Nice

Nice Work Bill!

Congrats on a job well done.

Seems I have seen that finish on the Burt Rutan canards from the 80's...kind of retro!

Nice Work Bill!

Congrats on a job well done.

Seems I have seen that finish on the Burt Rutan canards from the 80's...kind of retro!

Bill Boyd

Well Known Member

Doc, it's the cost of the equipment (pressure pot rig) and the skill required to do it right with the "real stuff."

The approach I used is for non-surgeons

I'm happy with how it turned out, and would do it again. I'd encourage you to try it as well, unless pressure spray equipment is something you'd want to invest in anyway. I sweated a bit before I cut loose with the spray can, imagining having to sand it all off and start over if I botched it. Nobody likes scut work, right? But it turned out fine. In the end it was a confidence-builder.

The approach I used is for non-surgeons

I'm happy with how it turned out, and would do it again. I'd encourage you to try it as well, unless pressure spray equipment is something you'd want to invest in anyway. I sweated a bit before I cut loose with the spray can, imagining having to sand it all off and start over if I botched it. Nobody likes scut work, right? But it turned out fine. In the end it was a confidence-builder.

Last edited:

snopercod

Well Known Member

I'm guessing "price". The darn stuff is up to $168 per quart now, plus shipping. Disclaimer: I used Zolatone Apollo Gray on my interior and am very pleased with the appearance and durability.why not just use the Zolatone products?

Bill Boyd

Well Known Member

Still working in the top while it's off and accessible

Masked off the lift strut brackets and the window "faux trim rings." Matte black should go with most any upholstery scheme I come up with. Fingers crossed. These decor decisions I would prefer to put off till whenever, but they're upon me if I want to do this while access is easy.

No matter how careful I am with masking, I _always_ seem to find a way to point something at a gap and let 'er rip. I'll try to fix this little blem with a Q-tip and lacquer thinner later. There's clear coat underneath, so maybe I can coax the black overspray off of there. Might have to reapply gray with a toothpick to hide it, though.

Masked off the lift strut brackets and the window "faux trim rings." Matte black should go with most any upholstery scheme I come up with. Fingers crossed. These decor decisions I would prefer to put off till whenever, but they're upon me if I want to do this while access is easy.

No matter how careful I am with masking, I _always_ seem to find a way to point something at a gap and let 'er rip. I'll try to fix this little blem with a Q-tip and lacquer thinner later. There's clear coat underneath, so maybe I can coax the black overspray off of there. Might have to reapply gray with a toothpick to hide it, though.

Mike S

Senior Curmudgeon

Bill Boyd

Well Known Member

Removes a little TOO much

Tried the Goof Off first. As I feared it might, it cut right through every layer at once. I gained some practice in spot repairs... practice I'd need later in the evening's work session...

...when I realized that what looked like shadows in the aft area was actually black overspray that misted down on the rear portion of the canopy top, beyond the masking paper! (If only I'd tossed a drop cloth over the unmasked portions of my work piece that I assumed were out of the range of the spray can ) I set to work trying to do something about the "tan lines" I had just discovered <<in retrospect, clearly visible in the middle photo of my previous post>>. I knew (by now) better than to touch them with solvent of any kind. Dry rubbing with paper towels took about half of it off, and blended the transition lines somewhat between overspray and pristine areas. I thought maybe a paper towel wet with water would do a better job.

) I set to work trying to do something about the "tan lines" I had just discovered <<in retrospect, clearly visible in the middle photo of my previous post>>. I knew (by now) better than to touch them with solvent of any kind. Dry rubbing with paper towels took about half of it off, and blended the transition lines somewhat between overspray and pristine areas. I thought maybe a paper towel wet with water would do a better job.

That's where I discovered that I had already rubbed through the matte clear enamel topcoat in these areas and made a second discovery: the black specks in the stone texture spray paint layer are water-soluble (this is why you aren't supposed to use this paint for outside projects without a protective clear coat). Carbon black smudges appeared everywhere. There was nothing else to do but carefully rub these areas down to the gray latex layer and reapply the stone paint and clear coat. Thankfully this was easier to blend in than I feared, and I'm happy enough with the result that I'm stepping back and leaving well enough alone. It's overhead and behind the passengers' heads, an area not seen except when loading the baggage area or judging a show plane, which this isn't.

I share this saga in the interest of full disclosure regarding the faux Zolatone process. It is inexpensive and easy, looks good when done right, and I believe it will withstand light use and careful cleaning of spills should they occur. It does NOT wear like nails (i.e. like real Zolatone would) and it's easy to screw up. I'd paint my window trim (or fabricate removable trim rings) first, before I did the faux finish. Easier to mask in that sequence and harder to mess up what's already done. I think if you baby this stuff it will serve well in non-traffic applications. It's not my recommendation for foot and hand traffic areas. Repairs don't appear complicated, except let's face it - if you have to fix this finish once the cabin top is installed, you're no longer working on the bench, but overhead, inside your (possibly otherwise-finished) plane. I hope never to go there.

Last night's experience does make me optimistic about the results I'll see when I have to blend the paint work I've already done inside the top with the paint that will go over the epoxy-micro that's going to fair the top into the fuselage sides around the door openings. I anticipate that the transitions between those two paint jobs will be hard to detect visually.

Do I wish I'd finished my top in shiny urethane that wears like iron but shows every surface imperfection? Tough call. I am having second thoughts. After making the front page with nice-looking photos, all I can do at this point is fully disclose how it's going. Each builder will have to decide whether they want to try this approach.

Tried the Goof Off first. As I feared it might, it cut right through every layer at once. I gained some practice in spot repairs... practice I'd need later in the evening's work session...

...when I realized that what looked like shadows in the aft area was actually black overspray that misted down on the rear portion of the canopy top, beyond the masking paper! (If only I'd tossed a drop cloth over the unmasked portions of my work piece that I assumed were out of the range of the spray can

That's where I discovered that I had already rubbed through the matte clear enamel topcoat in these areas and made a second discovery: the black specks in the stone texture spray paint layer are water-soluble (this is why you aren't supposed to use this paint for outside projects without a protective clear coat). Carbon black smudges appeared everywhere. There was nothing else to do but carefully rub these areas down to the gray latex layer and reapply the stone paint and clear coat. Thankfully this was easier to blend in than I feared, and I'm happy enough with the result that I'm stepping back and leaving well enough alone. It's overhead and behind the passengers' heads, an area not seen except when loading the baggage area or judging a show plane, which this isn't.

I share this saga in the interest of full disclosure regarding the faux Zolatone process. It is inexpensive and easy, looks good when done right, and I believe it will withstand light use and careful cleaning of spills should they occur. It does NOT wear like nails (i.e. like real Zolatone would) and it's easy to screw up. I'd paint my window trim (or fabricate removable trim rings) first, before I did the faux finish. Easier to mask in that sequence and harder to mess up what's already done. I think if you baby this stuff it will serve well in non-traffic applications. It's not my recommendation for foot and hand traffic areas. Repairs don't appear complicated, except let's face it - if you have to fix this finish once the cabin top is installed, you're no longer working on the bench, but overhead, inside your (possibly otherwise-finished) plane. I hope never to go there.

Last night's experience does make me optimistic about the results I'll see when I have to blend the paint work I've already done inside the top with the paint that will go over the epoxy-micro that's going to fair the top into the fuselage sides around the door openings. I anticipate that the transitions between those two paint jobs will be hard to detect visually.

Do I wish I'd finished my top in shiny urethane that wears like iron but shows every surface imperfection? Tough call. I am having second thoughts. After making the front page with nice-looking photos, all I can do at this point is fully disclose how it's going. Each builder will have to decide whether they want to try this approach.

Last edited:

Bill Boyd

Well Known Member

Next step...

Firewall insulation and stainless steel foil. (Giving myself a little break from the fiberglass fun I've been having since April.)

Planning to use only one heat muff and valve on advice of several VAFers who say one's enough in the RV-10. This begs the question: which side are we on, boys? (Apologies to Arlo Guthrie).

Will use a Y in the SCAT inside the tunnel to serve both front and rear heat vents. Firewall is of course pre-cut for two heated air pass-throughs. Any opinions as to whether 'tis better to block off the left hole or the right?

I guess I'll have to secure some firewall-thickness stainless to patch the unused hole. Maybe McMaster.

Firewall insulation and stainless steel foil. (Giving myself a little break from the fiberglass fun I've been having since April.)

Planning to use only one heat muff and valve on advice of several VAFers who say one's enough in the RV-10. This begs the question: which side are we on, boys? (Apologies to Arlo Guthrie).

Will use a Y in the SCAT inside the tunnel to serve both front and rear heat vents. Firewall is of course pre-cut for two heated air pass-throughs. Any opinions as to whether 'tis better to block off the left hole or the right?

I guess I'll have to secure some firewall-thickness stainless to patch the unused hole. Maybe McMaster.

az_gila

Well Known Member

I'm guessing "price". The darn stuff is up to $168 per quart now, plus shipping. Disclaimer: I used Zolatone Apollo Gray on my interior and am very pleased with the appearance and durability.

Isn't this the stuff? $142 per gallon, not per qt.

https://www.autobodytoolmart.com/zolatone-20-apollo-gray-gallon-20-11-1g-p-31874.aspx

snopercod

Well Known Member

Yes! That's the stuff! I was quoting Aircraft Spruce prices. Thanks for the tip.Isn't this the stuff?

Bill Boyd

Well Known Member

Okay, so no opinions offered on which of the heater holes to block off. I chose the right. I'll put my S.S. heater box over the left-side hole. Fibrefrax has been cut to fit; the build rolls on

Now the question arises whether to install this insulation and stainless foil overlay before or after fitting the cowl attach hinges. I wouldn't apply the fire barrier silicone caulk around the edges before the hinges but it almost looks like the fibrefrax and foil alone wouldn't be much in the way.

I'm debating alternative fasteners for the top hinges. In 20 years of messing with my 6A cowl, the top two are the only hinges that have been a hassle. (And the bottom hinges were replaced with plates and screws at the first sign of cracking, a few hours in...)

Now the question arises whether to install this insulation and stainless foil overlay before or after fitting the cowl attach hinges. I wouldn't apply the fire barrier silicone caulk around the edges before the hinges but it almost looks like the fibrefrax and foil alone wouldn't be much in the way.

I'm debating alternative fasteners for the top hinges. In 20 years of messing with my 6A cowl, the top two are the only hinges that have been a hassle. (And the bottom hinges were replaced with plates and screws at the first sign of cracking, a few hours in...)

az_gila

Well Known Member

Yes! That's the stuff! I was quoting Aircraft Spruce prices. Thanks for the tip.

Whoa... that's a heck of a difference!!

Kyle Boatright

Well Known Member

Okay, so no opinions offered on which of the heater holes to block off. I chose the right. I'll put my S.S. heater box over the left-side hole. Fibrefrax has been cut to fit; the build rolls on

Now the question arises whether to install this insulation and stainless foil overlay before or after fitting the cowl attach hinges. I wouldn't apply the fire barrier silicone caulk around the edges before the hinges but it almost looks like the fibrefrax and foil alone wouldn't be much in the way.

I'm debating alternative fasteners for the top hinges. In 20 years of messing with my 6A cowl, the top two are the only hinges that have been a hassle. (And the bottom hinges were replaced with plates and screws at the first sign of cracking, a few hours in...)

My opinion (and I'm neck and neck with you on the build) is that it doesn't really matter if you attach the hinges or any firewall protection first.

Personally, I'm going with Camloc's along the top and bottom of the firewall. The screws I used there on the -6 have worked well, but removing 20 of 'em gets old, and it would take even more on the -10. I'll go with the hinges on the vertical firewall sides and along the top/bottom split - that's how my -6 is.

Bob Martin

Well Known Member

Camloc

Bill,

When we converted both our -6's to the James cowlings, one thing we wanted was to rid ourselves of the hinges. We installed Milspecs all around and love it.

Skybolt does have the ready made metal interlocking tabs that simplify the firewall connection, but we used Larry's router table to make alum strips with scallops. That way we didn't have joints between the scallops and I think it is stronger for it.

When I was making the decision as to which brand, I looked and the product seems the same, but Milspec was cheaper. Now, Skybolt does do a better job supporting their product and offering directions and as mentioned earlier, the locking tabs for those that need them. Also they are a VAF advertiser as well! But pretty sure you will find the Milspecs cheaper and I found them to work very well.

PS.....I like your new avitar......seems more manly than mine....

Pretty much my thoughts, Kyle. Those top and bottom hinges are enough trouble I'm surprised Van hasn't relegated them to buggy whip status.

Now the question is Skybolt vs. Camloc.

Bill,

When we converted both our -6's to the James cowlings, one thing we wanted was to rid ourselves of the hinges. We installed Milspecs all around and love it.

Skybolt does have the ready made metal interlocking tabs that simplify the firewall connection, but we used Larry's router table to make alum strips with scallops. That way we didn't have joints between the scallops and I think it is stronger for it.

When I was making the decision as to which brand, I looked and the product seems the same, but Milspec was cheaper. Now, Skybolt does do a better job supporting their product and offering directions and as mentioned earlier, the locking tabs for those that need them. Also they are a VAF advertiser as well! But pretty sure you will find the Milspecs cheaper and I found them to work very well.

PS.....I like your new avitar......seems more manly than mine....

Last edited:

Bill Boyd

Well Known Member

Thanks for your thoughts, Bob

I never minded the vertical side hinges on my 6A. They work smoothly and hold well - attaching the bottom cowl half by myself it's nice to drop that first pin in and know I can let go to attend to the rest of the attach points without worry of it going anywhere.

As to Camlocs and Skybolts, I found an old thread yesterday that suggests MilSpec may have them both beat in some regards. I'm still researching, but likely going with a hybrid combo of hinges, quarter-turn fasteners and #8 screws with Tinnerman washers in the places where each excels.

I never minded the vertical side hinges on my 6A. They work smoothly and hold well - attaching the bottom cowl half by myself it's nice to drop that first pin in and know I can let go to attend to the rest of the attach points without worry of it going anywhere.

As to Camlocs and Skybolts, I found an old thread yesterday that suggests MilSpec may have them both beat in some regards. I'm still researching, but likely going with a hybrid combo of hinges, quarter-turn fasteners and #8 screws with Tinnerman washers in the places where each excels.

Neat epoxy applied over the squeegied/sanded micro coat. Time for a TON of wet-sanding using the DanH stippled roller coat method.

Cee Bailey put the plexiglass on the truck today. SilPruf on hand. Should be a fun few weeks

Do you have a link to one of DanH's threads discussing this technique?

Last edited:

Bill Boyd

Well Known Member

Haven't updated progress in awhile in my own thread

so here goes.

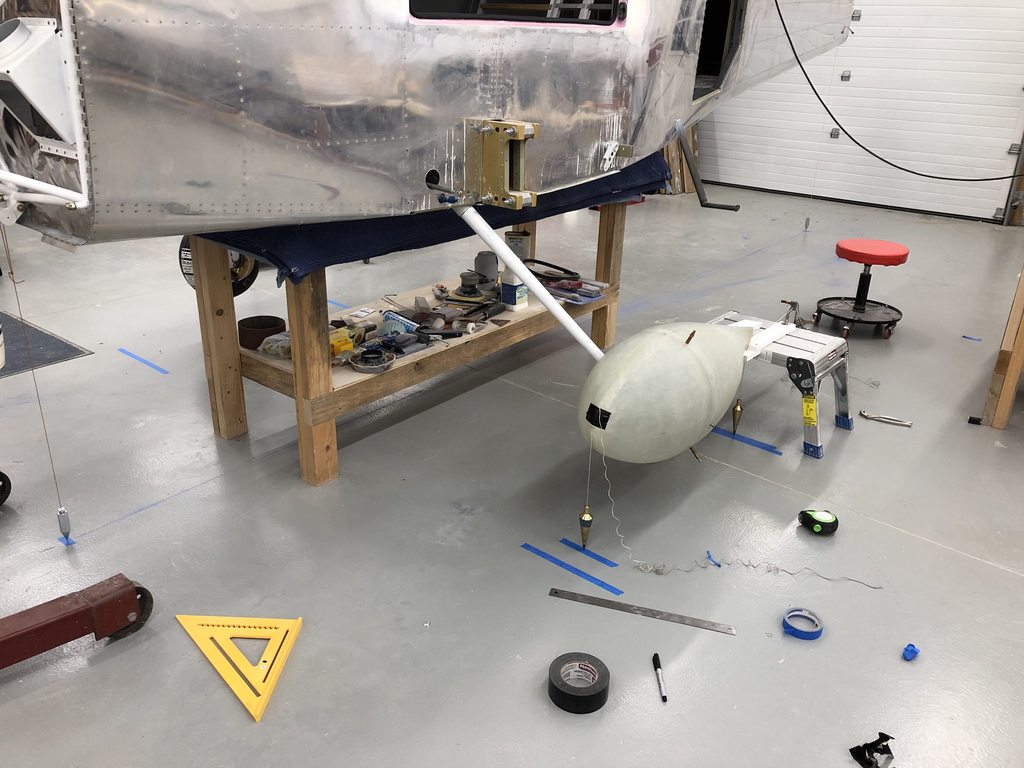

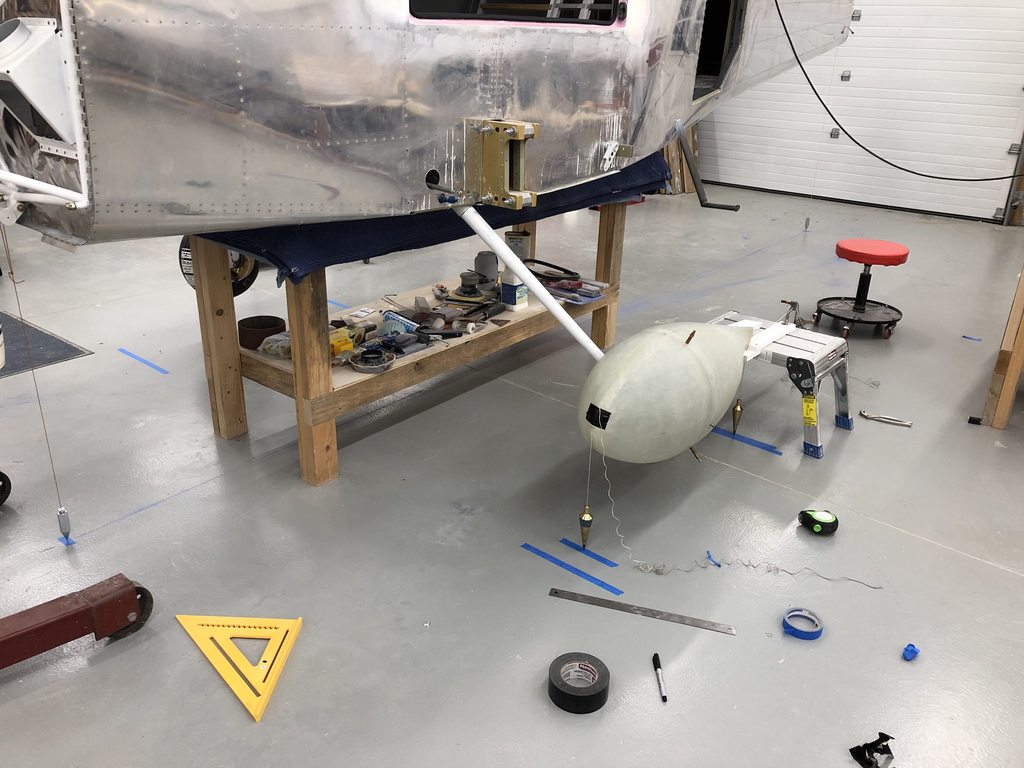

I was pretty much running out of things to do before drilling the gear legs and messing with seat tracks and such. By that I mean, lacking an avionics suite, there wasn't much more to do during the easy-access stage where the fuse is on a rolling dolly down close to the floor.

Time to spit on my hands, rub them together, hoist the Jolly Roger and slit a few throats.

And sweat a few bullets.

Reminder to self: moments like this are why we carry builder's insurance.

After much pondering I decided there was no need to make a sawhorse just for this job. The EAA workbenches I have on hand should be tall enough at 34" and will certainly hold the weight. Tail resting on one bench, engine mount double-strapped to engine hoist, up she goes! Slowly. Ever so slowly. Check everything twice, three times... The fuse canoe hasn't been off this trolley since I inspected the project in Columbus, Ohio three years ago.

Finally, high enough to pull the trolley out of the way and slide the bench under.

Two parting shots showing the gear legs installed. Whew! Big step! 34" bench height seems to give plenty of ground clearance for wheel installation. I'll know for sure tonight.

so here goes.

I was pretty much running out of things to do before drilling the gear legs and messing with seat tracks and such. By that I mean, lacking an avionics suite, there wasn't much more to do during the easy-access stage where the fuse is on a rolling dolly down close to the floor.

Time to spit on my hands, rub them together, hoist the Jolly Roger and slit a few throats.

And sweat a few bullets.

Reminder to self: moments like this are why we carry builder's insurance.

After much pondering I decided there was no need to make a sawhorse just for this job. The EAA workbenches I have on hand should be tall enough at 34" and will certainly hold the weight. Tail resting on one bench, engine mount double-strapped to engine hoist, up she goes! Slowly. Ever so slowly. Check everything twice, three times... The fuse canoe hasn't been off this trolley since I inspected the project in Columbus, Ohio three years ago.

Finally, high enough to pull the trolley out of the way and slide the bench under.

Two parting shots showing the gear legs installed. Whew! Big step! 34" bench height seems to give plenty of ground clearance for wheel installation. I'll know for sure tonight.

rv7charlie

Well Known Member

Bill,

I did roughly the same thing with my -7 fuselage. I fit and aligned the leg fairings & wheel pants, too, before ever hanging the engine. I then removed the gear legs, and using stub pipe 'legs', returned the fuselage to a low dolly to ease continued work on/in the fuselage. I eventually hung the engine & did all its hookups with the fuselage still on the low dolly. Don't know if you can do that with a trike, but it worked out well for my taildragger -7.

Charlie

I did roughly the same thing with my -7 fuselage. I fit and aligned the leg fairings & wheel pants, too, before ever hanging the engine. I then removed the gear legs, and using stub pipe 'legs', returned the fuselage to a low dolly to ease continued work on/in the fuselage. I eventually hung the engine & did all its hookups with the fuselage still on the low dolly. Don't know if you can do that with a trike, but it worked out well for my taildragger -7.

Charlie

Bill Boyd

Well Known Member

Good thoughts, Charlie.

The gear would come back off easily enough. As long as I don't chop up the low dolly for firewood (and a rear tie-down rolling tripod stand) in the mean time, I guess that's an option.

I'm not sure I could bear the suspense of seeing all that time and money dangling from a ratchet strap ever again.

Might be better off building a platform and steps for easier in-out and leaving her on tires, tires on caster dollies - easy peasy. It's how I did the final stages of the 6A so long ago.

The gear would come back off easily enough. As long as I don't chop up the low dolly for firewood (and a rear tie-down rolling tripod stand) in the mean time, I guess that's an option.

I'm not sure I could bear the suspense of seeing all that time and money dangling from a ratchet strap ever again.

Might be better off building a platform and steps for easier in-out and leaving her on tires, tires on caster dollies - easy peasy. It's how I did the final stages of the 6A so long ago.

Bill Boyd

Well Known Member

Seat adjusters cobbled up

Read some descriptions of what others have done, so I thought I'd try my hand at rolling my own.

Hollowed out the underside of a length of 1/2" square aluminum bar stock from Spruce by multiple dado passes on a table saw. Bent where necessary in a vise, by hand. Holes drilled using That Looks About Right engineering and Mk. I eyeballs.

Bushings around the pivot bolt and an elongated hole let the lever arm move fore and aft a bit, so the seat adjuster plunger doesn't get pulled sideways into a bind in the barrel. Surplus wheel pant/axle nut spacers (Van's hex stock) repurposed into handles.

It works! Net added weight is 4.2oz per seat (minus the weight of the T-handles that are replaced.) Don't hate on my epoxy bench - the coating of microballoons shows it's well used - and that I'm too busy building to bother with housekeeping.

Ta-daa!

Read some descriptions of what others have done, so I thought I'd try my hand at rolling my own.

Hollowed out the underside of a length of 1/2" square aluminum bar stock from Spruce by multiple dado passes on a table saw. Bent where necessary in a vise, by hand. Holes drilled using That Looks About Right engineering and Mk. I eyeballs.

Bushings around the pivot bolt and an elongated hole let the lever arm move fore and aft a bit, so the seat adjuster plunger doesn't get pulled sideways into a bind in the barrel. Surplus wheel pant/axle nut spacers (Van's hex stock) repurposed into handles.

It works! Net added weight is 4.2oz per seat (minus the weight of the T-handles that are replaced.) Don't hate on my epoxy bench - the coating of microballoons shows it's well used - and that I'm too busy building to bother with housekeeping.

Ta-daa!

Last edited:

Bill Boyd

Well Known Member

preview of coming attractions

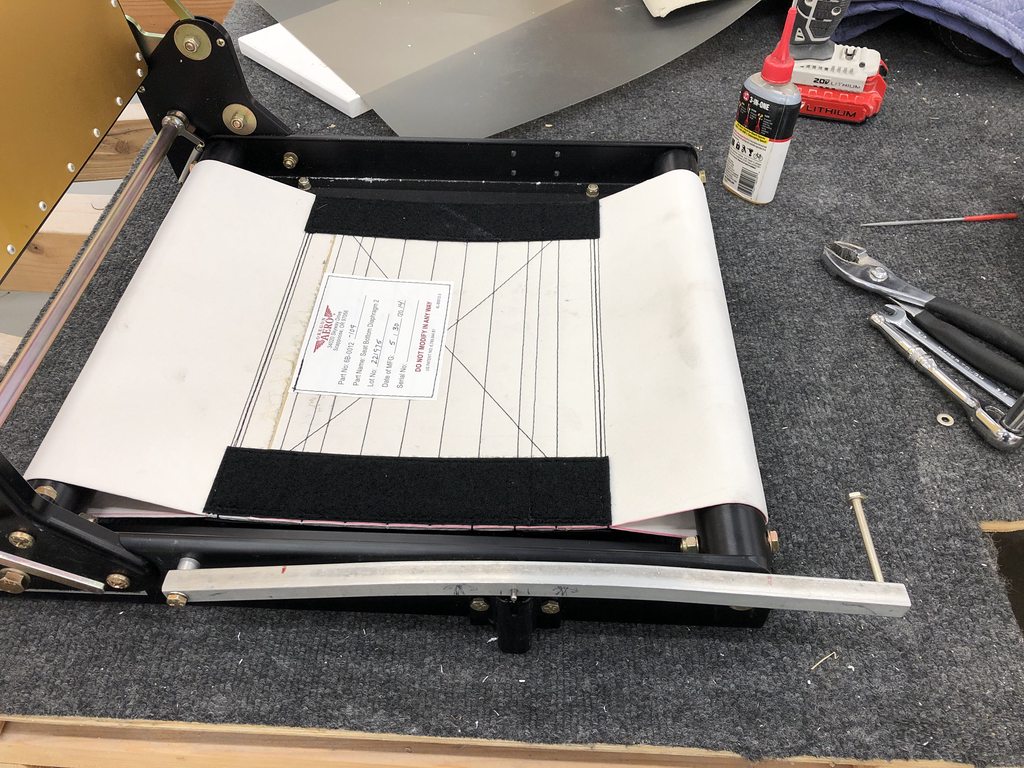

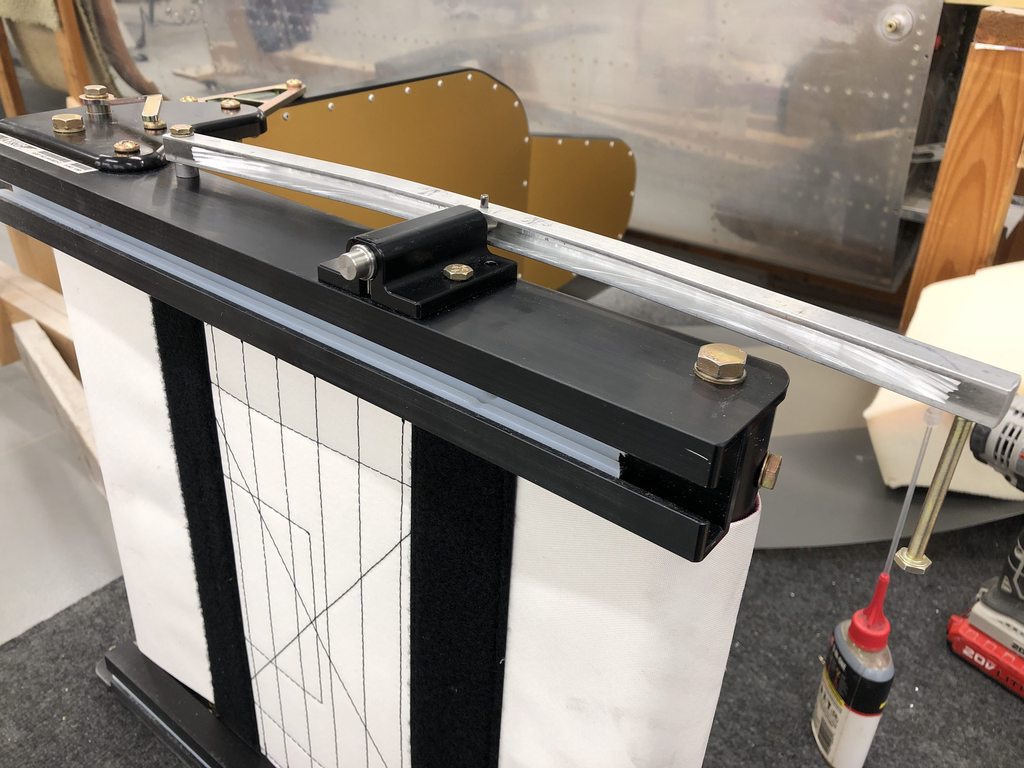

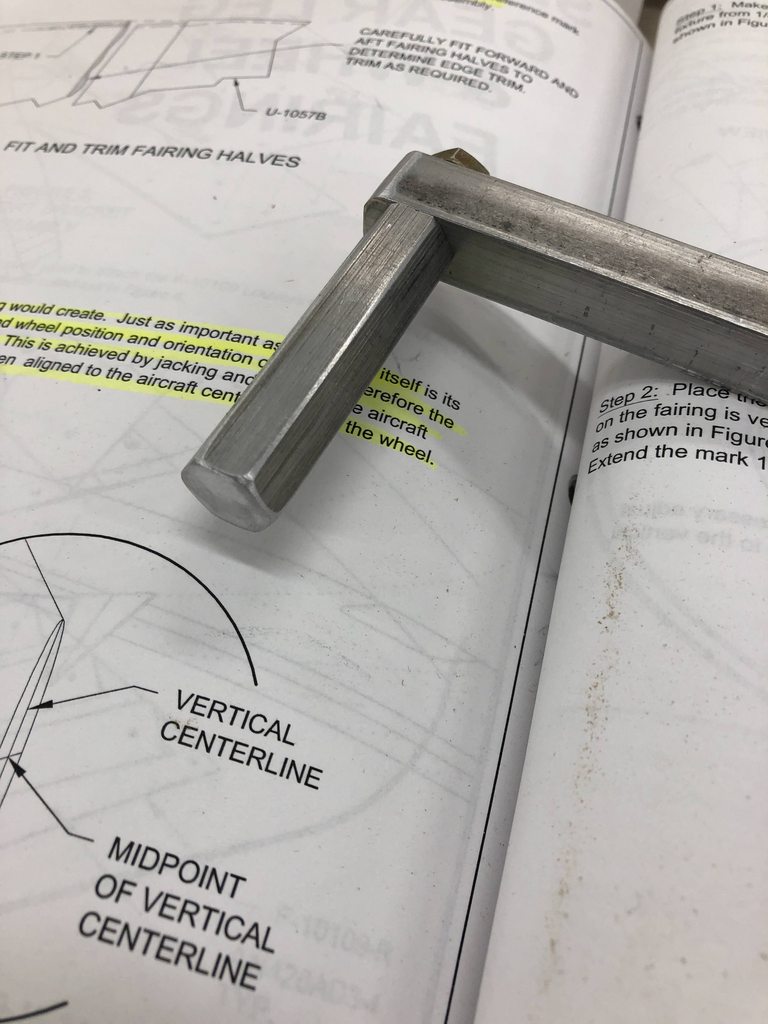

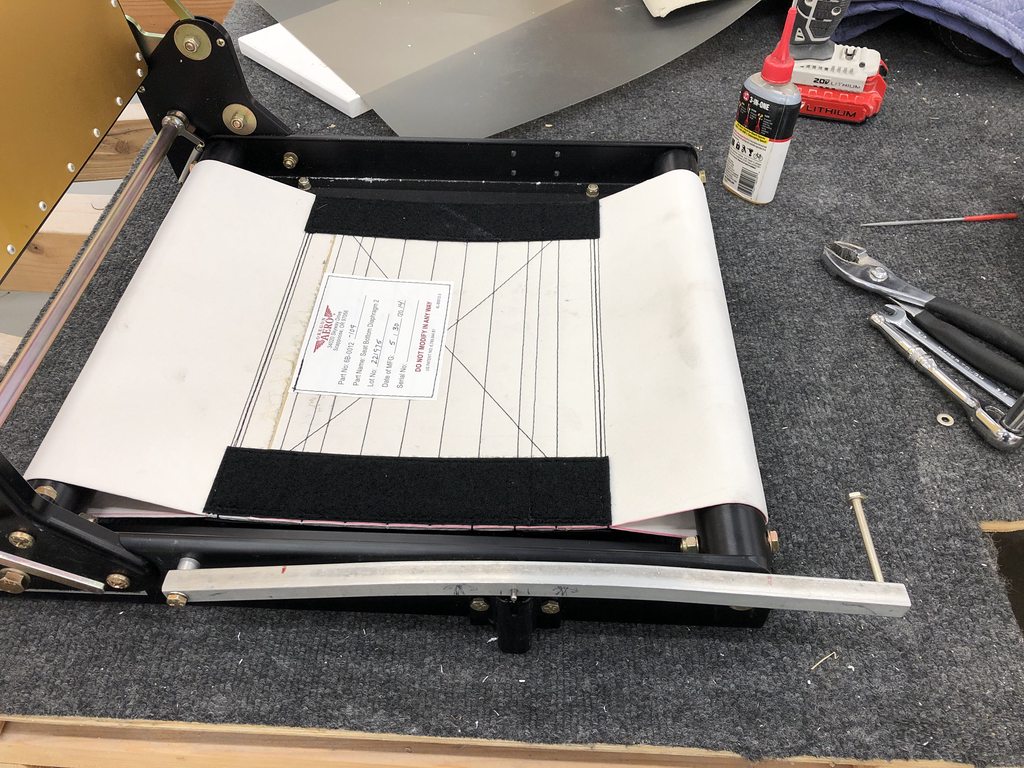

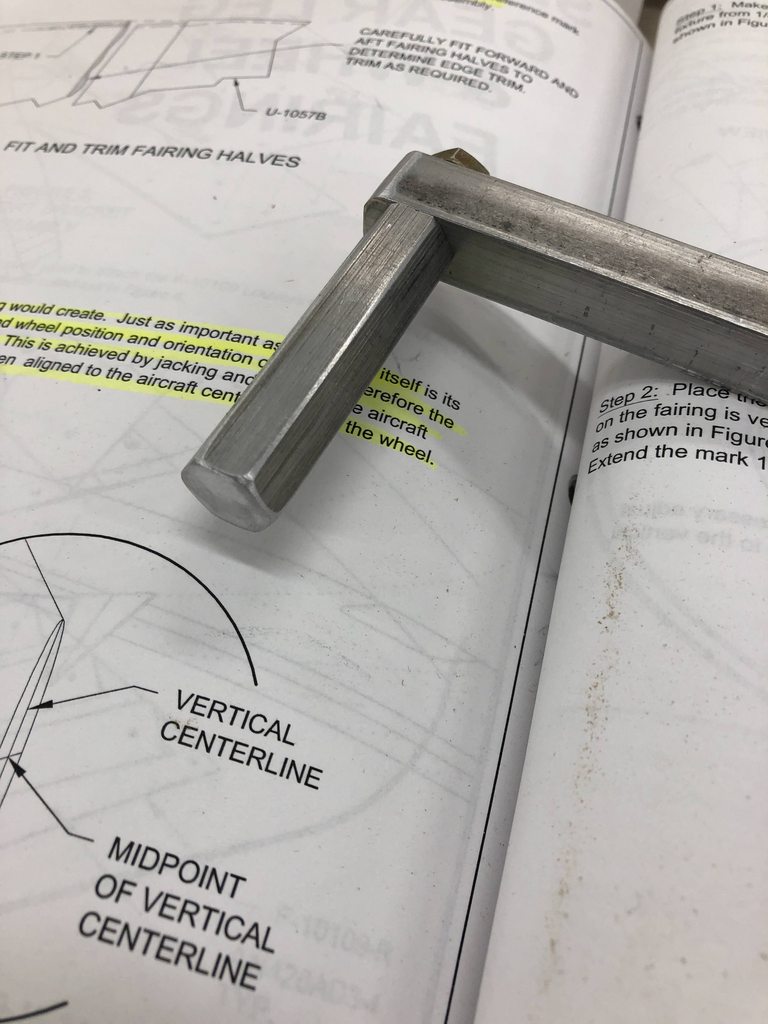

Say hello to my little friend Bob. Plumb Bob.

Cutting and fitting to reference points in thin air. Don't. let. anything. shift. Drill through fiberglass into landmarks you can barely see - at an angle. This may be the part of the story where I jump off a bridge.

Not sure; those that have gone before say the cowling will also be... "interesting."

Say hello to my little friend Bob. Plumb Bob.

Cutting and fitting to reference points in thin air. Don't. let. anything. shift. Drill through fiberglass into landmarks you can barely see - at an angle. This may be the part of the story where I jump off a bridge.

Not sure; those that have gone before say the cowling will also be... "interesting."

Bob Martin

Well Known Member

Hi Bill....Bob here

Brings back memories.....not fond either.

At least you don't have wings in the way.

I remember taping Christmas tree lights inside the pant behind the brackets to help find the holes.....worked well.

Also used a 24" level....check, check, recheck....drill....

Brings back memories.....not fond either.

At least you don't have wings in the way.

I remember taping Christmas tree lights inside the pant behind the brackets to help find the holes.....worked well.

Also used a 24" level....check, check, recheck....drill....

Bill Boyd

Well Known Member

Everyone at Van's Anonymous support group: "Hello, Bob."

The -10 plans take an interesting approach: drill mounting holes undersize, tap holes in brackets for small screws, try to insert screws, enlarge holes in pants with round file in whatever direction they need to "move," drill final size after filling any erroneous parts of the first hole attempt with flox.

Iterative.

And a veiled acknowledgement of how difficult it probably is to get the holes any kind of right on the first stab at it. I'm looking forward to the challenge, remembering that while I want to get this right, we're not building the Space Shuttle here. A little misalignment of the watermelons probably costs an unmeasurable fraction of a knot, the leg fairings being the more critical factor.

The -10 plans take an interesting approach: drill mounting holes undersize, tap holes in brackets for small screws, try to insert screws, enlarge holes in pants with round file in whatever direction they need to "move," drill final size after filling any erroneous parts of the first hole attempt with flox.

Iterative.

And a veiled acknowledgement of how difficult it probably is to get the holes any kind of right on the first stab at it. I'm looking forward to the challenge, remembering that while I want to get this right, we're not building the Space Shuttle here. A little misalignment of the watermelons probably costs an unmeasurable fraction of a knot, the leg fairings being the more critical factor.

rv7charlie

Well Known Member

Forgive my flaky memory; has the use of a laser level been discussed for aligning the pants? I found that a cheap HF laser level was quite useful in aligning the pants. I set mine up to paint a stripe on the centerline of the tire tread, then put the pant in place, tweaking the angles to align it with the laser line.

Charlie

edit: should have said it was on a -7; not a -10

Charlie

edit: should have said it was on a -7; not a -10

CLARIFICATION..........

The process specified in the plans is for a very specific reason, and the reason is not to fix wallowed out holes that occurred during the fitting process.

It also gives extra adjustment options to allow for some level of precision. Alignment does matter. We are talking about way more than a fraction of a knot, depending on how much the alignment is off. It is likely one of the factors in play when an RV doesn't seem to have the same speed that most do.

- The fiberglass on the fairings is relatively thin. Durability would be poor if the screws were only bearing on the thickness of the fairing itself.

- A lot of strength is gained by having the flox fill, capture the perimeter of the bracket.

- The fairings are curved, but the bracket faces that they interface to are flat. If the flox is not used, the fairing will deform with flat spots where all the screws are located.

- The taped holes and screws are used because if you used clecos during the flox placement, they would suck the fairing flat to the bracket and defeat most of the benefit of adding the flox.

- Screws are also used because once the fairing is properly aligned, tolerance stack up usually causes the brackets to have differing amounts of gap at each screw location. With screws, you have some adjustment to account for the different gaps. Once again, if you where using clecos, accounting for this would not be possible and there would be no way to prevent the clecos from pulling the fairing out of alignment.

Bottom line... a lack of understanding of the purpose behind a procedure in the construction manual does not mean it isn't important......

The -10 plans take an interesting approach: drill mounting holes undersize, tap holes in brackets for small screws, try to insert screws, enlarge holes in pants with round file in whatever direction they need to "move," drill final size after filling any erroneous parts of the first hole attempt with flox.

Iterative.

And a veiled acknowledgement of how difficult it probably is to get the holes any kind of right on the first stab at it. I'm looking forward to the challenge, remembering that while I want to get this right, we're not building the Space Shuttle here. A little misalignment of the watermelons probably costs an unmeasurable fraction of a knot, the leg fairings being the more critical factor.

The process specified in the plans is for a very specific reason, and the reason is not to fix wallowed out holes that occurred during the fitting process.

It also gives extra adjustment options to allow for some level of precision. Alignment does matter. We are talking about way more than a fraction of a knot, depending on how much the alignment is off. It is likely one of the factors in play when an RV doesn't seem to have the same speed that most do.

- The fiberglass on the fairings is relatively thin. Durability would be poor if the screws were only bearing on the thickness of the fairing itself.

- A lot of strength is gained by having the flox fill, capture the perimeter of the bracket.

- The fairings are curved, but the bracket faces that they interface to are flat. If the flox is not used, the fairing will deform with flat spots where all the screws are located.

- The taped holes and screws are used because if you used clecos during the flox placement, they would suck the fairing flat to the bracket and defeat most of the benefit of adding the flox.

- Screws are also used because once the fairing is properly aligned, tolerance stack up usually causes the brackets to have differing amounts of gap at each screw location. With screws, you have some adjustment to account for the different gaps. Once again, if you where using clecos, accounting for this would not be possible and there would be no way to prevent the clecos from pulling the fairing out of alignment.

Bottom line... a lack of understanding of the purpose behind a procedure in the construction manual does not mean it isn't important......