romanov

Well Known Member

.

Hello to all of you - mighty airplane builders,

Today we are happy to add our progress thread

to the community forum.

So who are we?

We are two best friends since 8th grade which

makes it 25 years already (...daaa***mn we

are old!!!) and we decided to make this awesome

dream to come true.

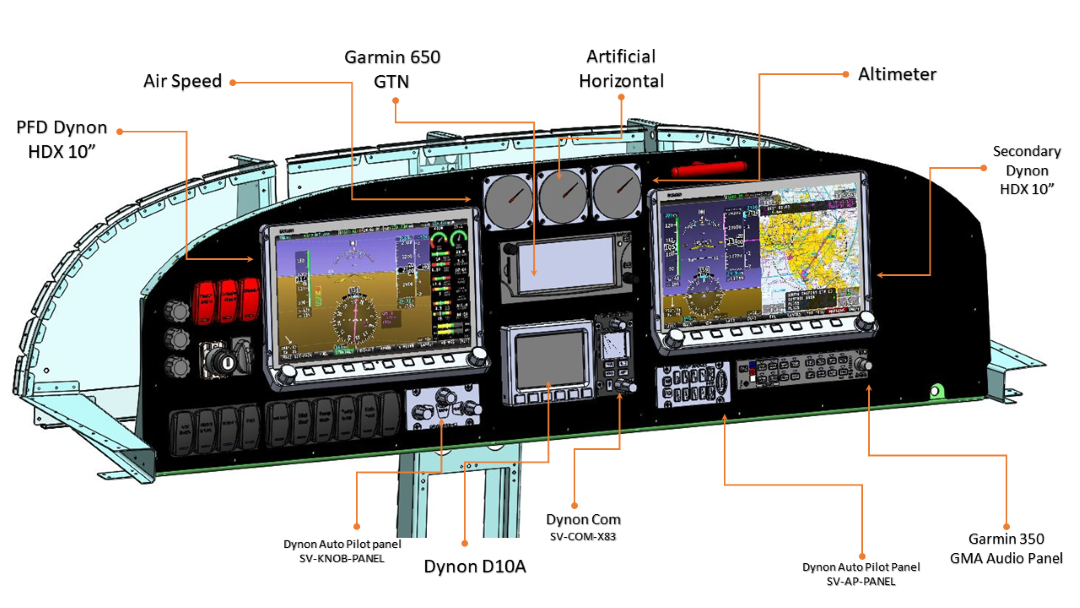

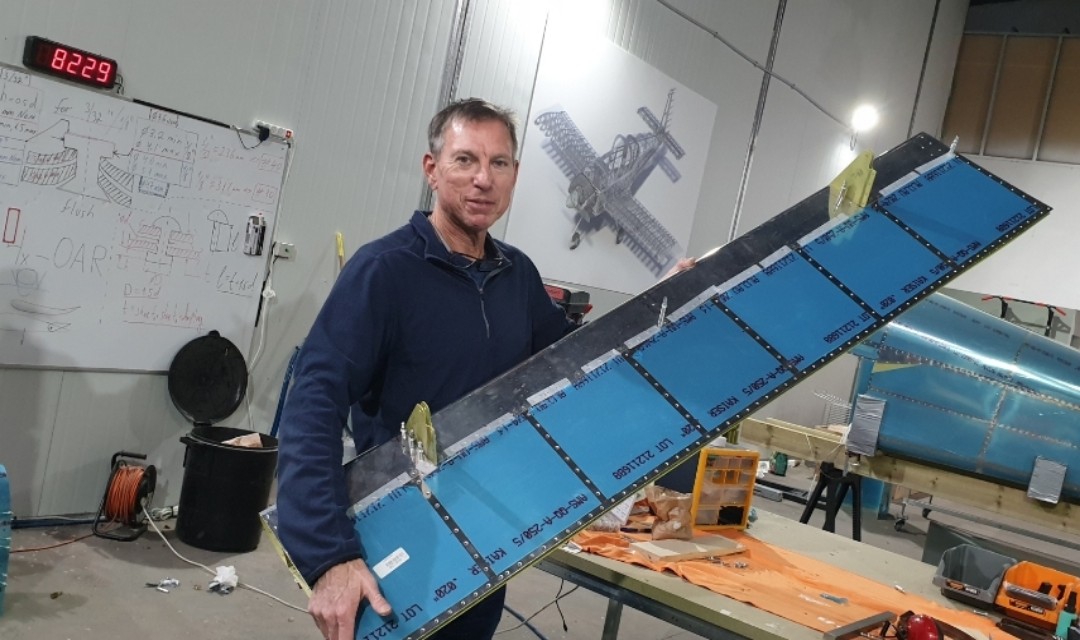

Roman - I am a retired soft developer

and studying pilot, for that moment I have only 13

hours of Cessna 152. I hope to have my license

before the construction is done. I am huge fan of

Vans and avionics enthusiast.

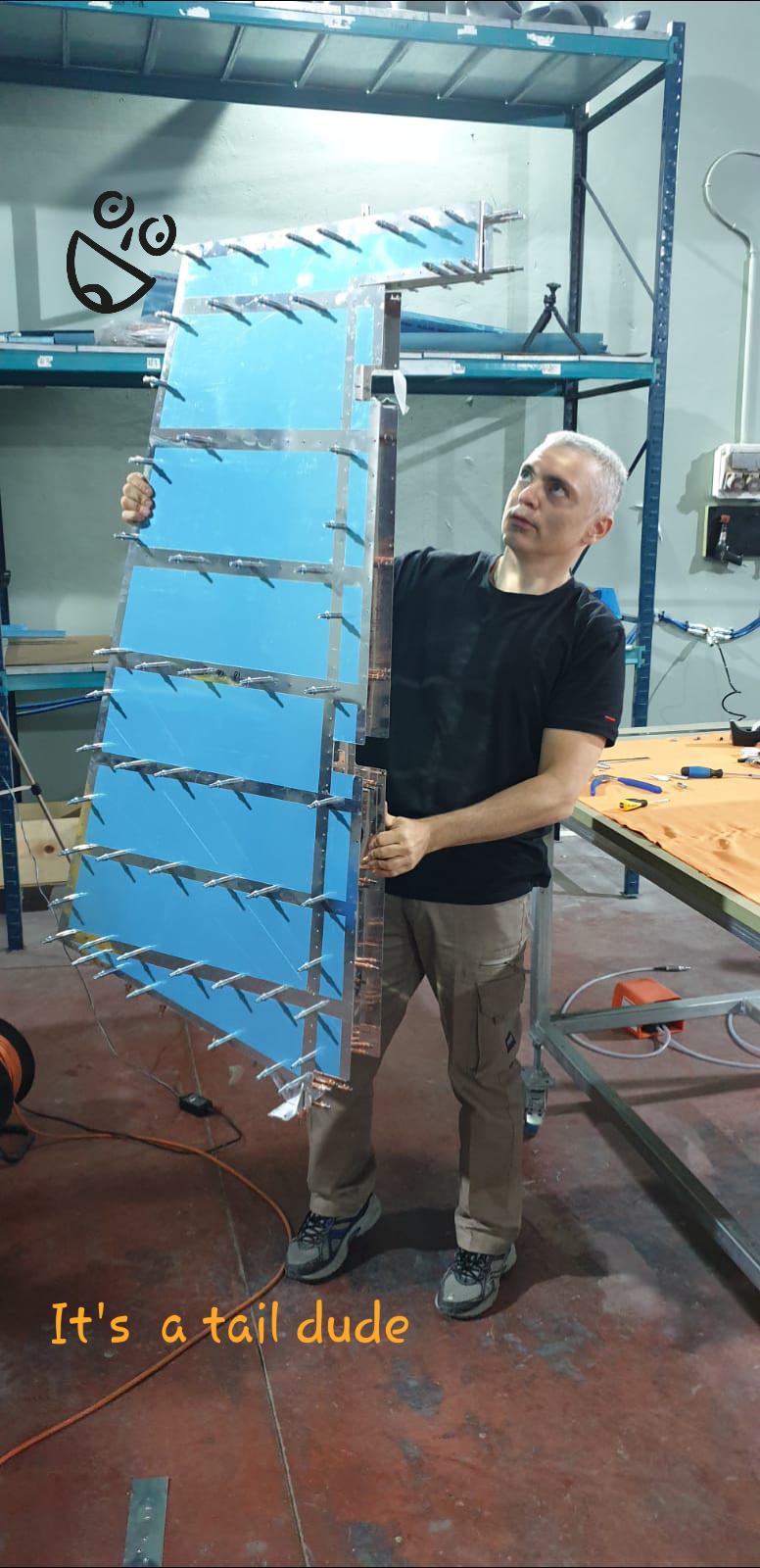

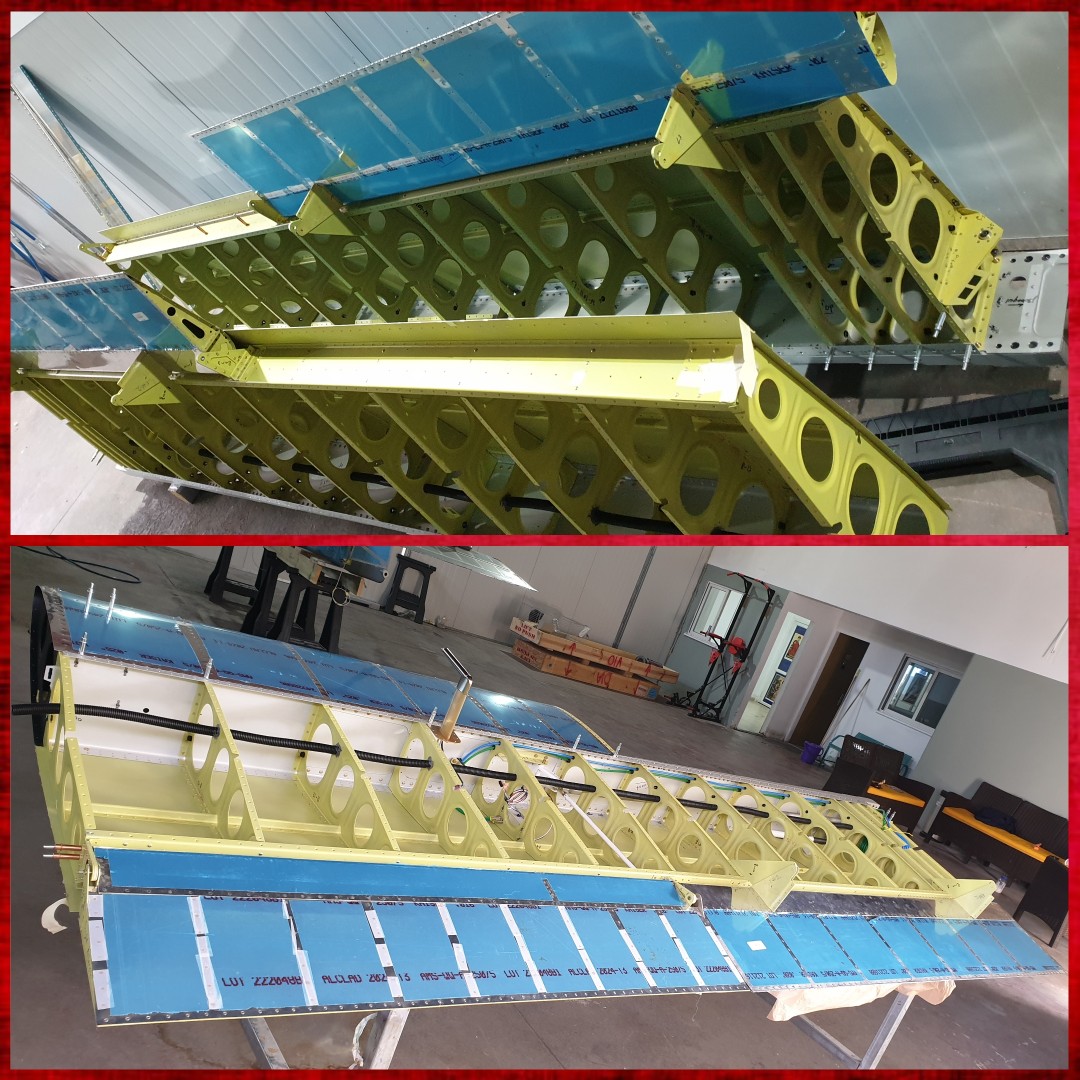

Dima - A guy who is super excited

about constructing things. A GE ex-engineer (yes,

we have a local branch). Dima decided to put his

day job on hold for some months and dedicate

next months exclusively to the project.

.

18 months is the timeframe we are planning to have

the plane flying. Some will say it is optimistics for

first time builders. But we are super determined to

prove it's doable.

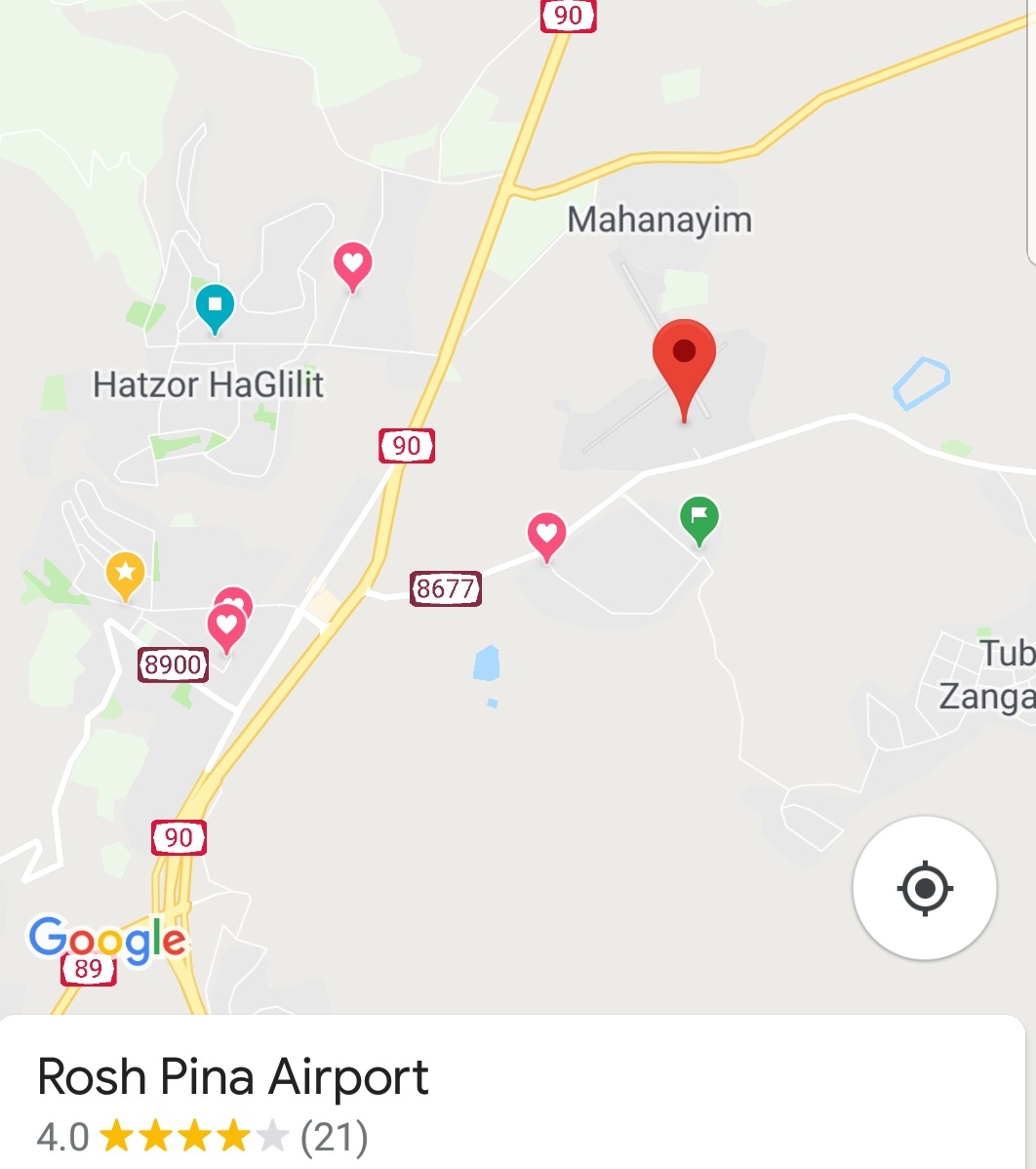

I think it is the first project to give a full progress

report from Israel (maybe not the only builder here,

but the only one to report here) and even though

we feel very distant from the community we are

virtually very attached. We are reading dozens of

blogs and studying from all of you so much so

sometimes it feels like we know all and each of you

personally.

The big dream for us is one day to take off from

Israel on our self-constructed RV14a to cross the

ocean and land on one of the events you guys are

organizing in U.S. Yes it is possible, the navigation

path was already planned, and what left is just to

build the plane.

Guys, please give us some spiritual support. I hope

to shake hands with all of you very soon!

P.S: Will post our first actual status update in a day or two.

Cheers.

Roman & Dima

Introduction:

Hello to all of you - mighty airplane builders,

Today we are happy to add our progress thread

to the community forum.

So who are we?

We are two best friends since 8th grade which

makes it 25 years already (...daaa***mn we

are old!!!) and we decided to make this awesome

dream to come true.

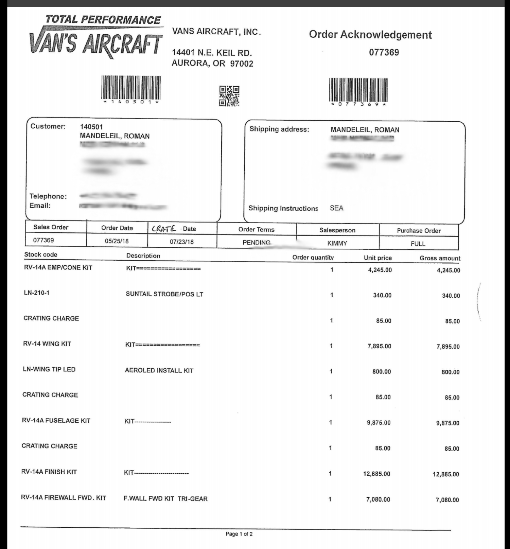

Roman - I am a retired soft developer

and studying pilot, for that moment I have only 13

hours of Cessna 152. I hope to have my license

before the construction is done. I am huge fan of

Vans and avionics enthusiast.

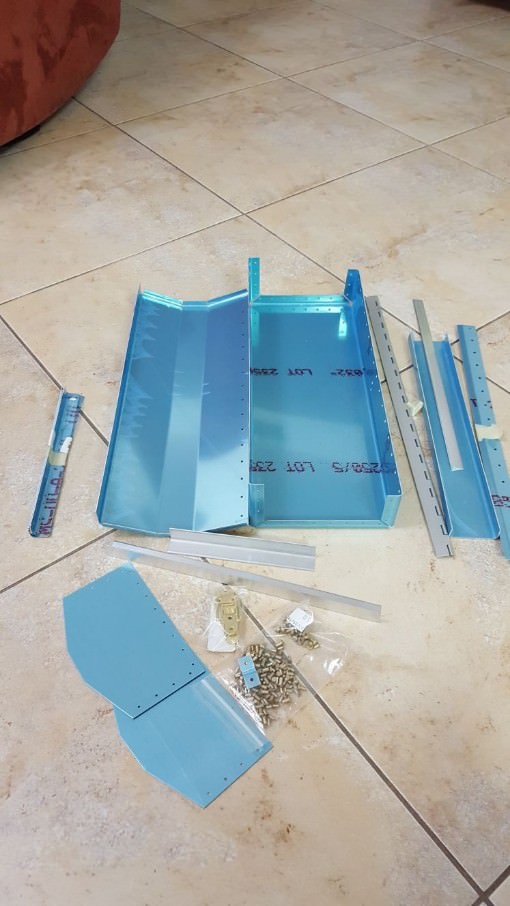

Dima - A guy who is super excited

about constructing things. A GE ex-engineer (yes,

we have a local branch). Dima decided to put his

day job on hold for some months and dedicate

next months exclusively to the project.

.

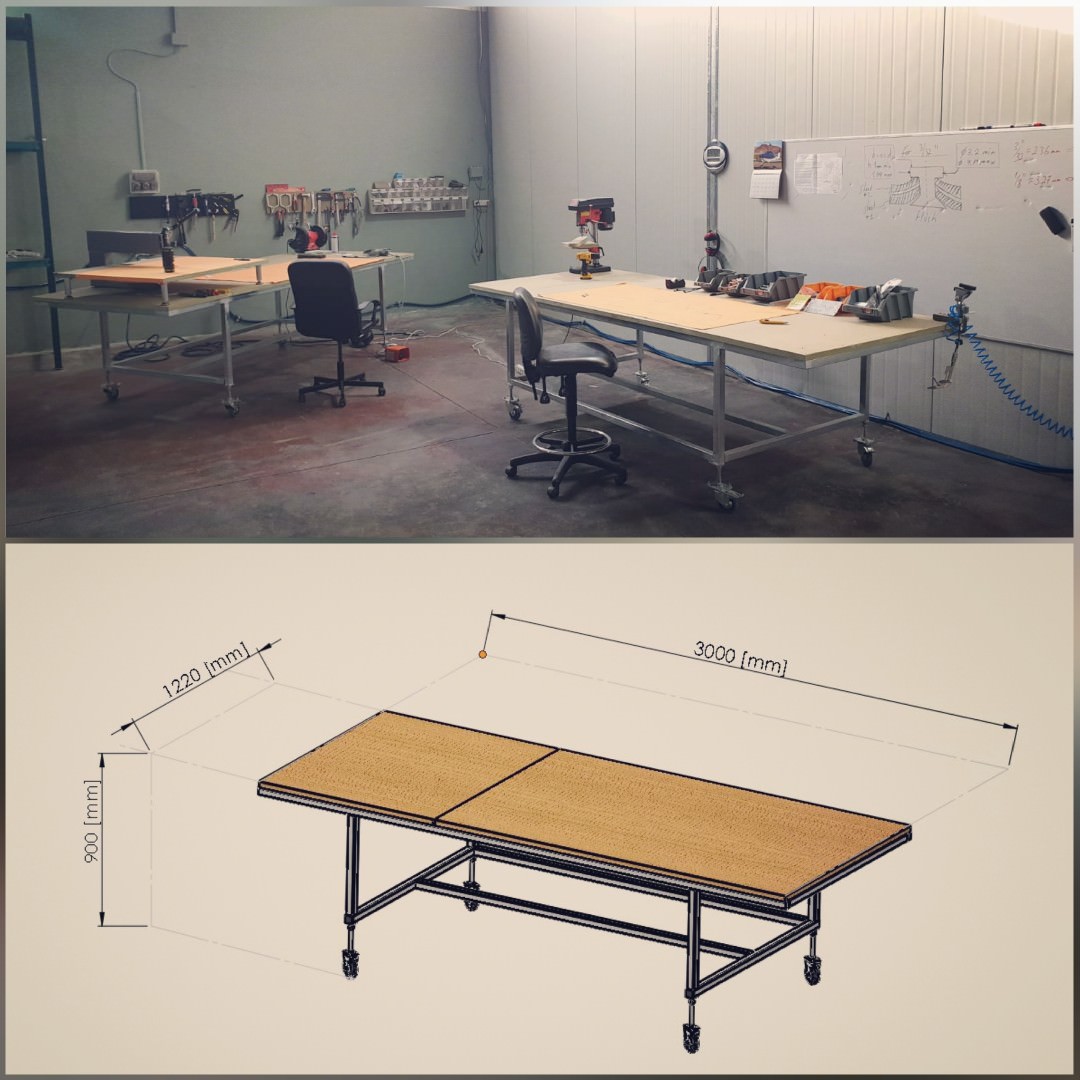

18 months is the timeframe we are planning to have

the plane flying. Some will say it is optimistics for

first time builders. But we are super determined to

prove it's doable.

I think it is the first project to give a full progress

report from Israel (maybe not the only builder here,

but the only one to report here) and even though

we feel very distant from the community we are

virtually very attached. We are reading dozens of

blogs and studying from all of you so much so

sometimes it feels like we know all and each of you

personally.

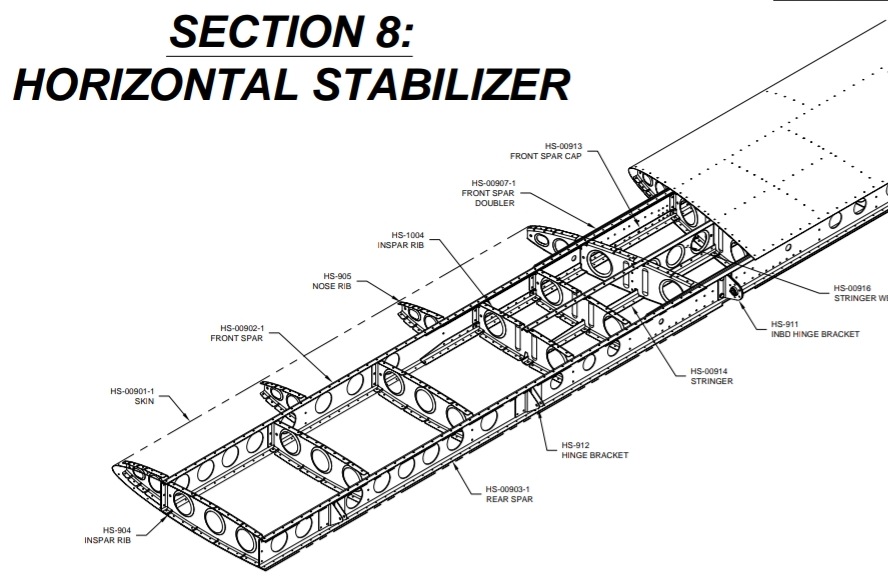

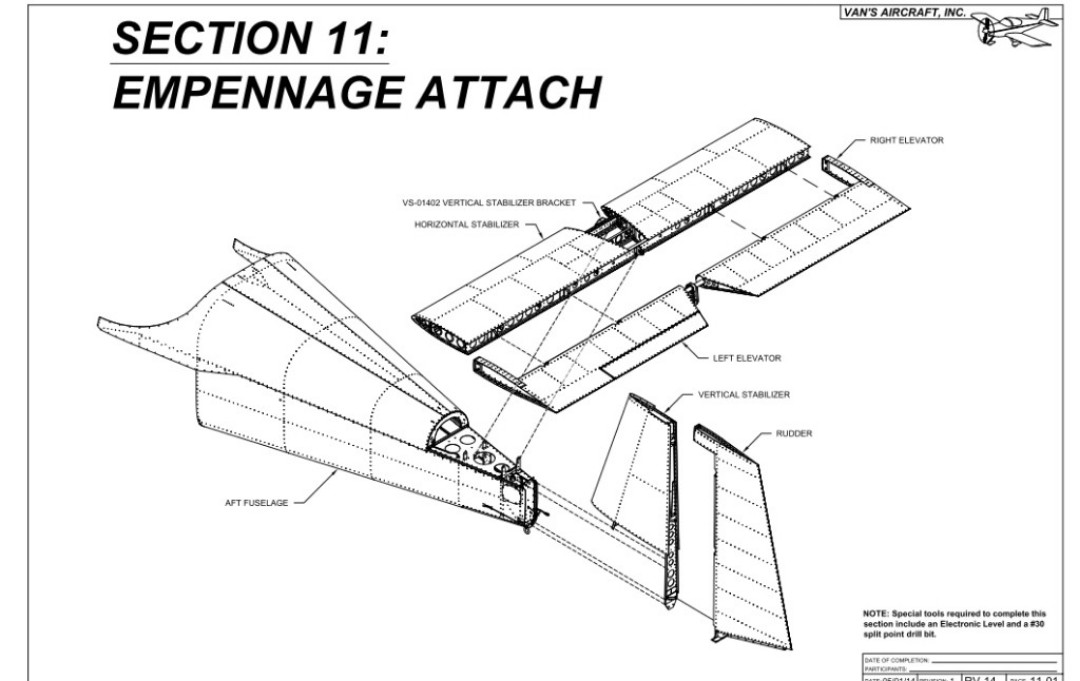

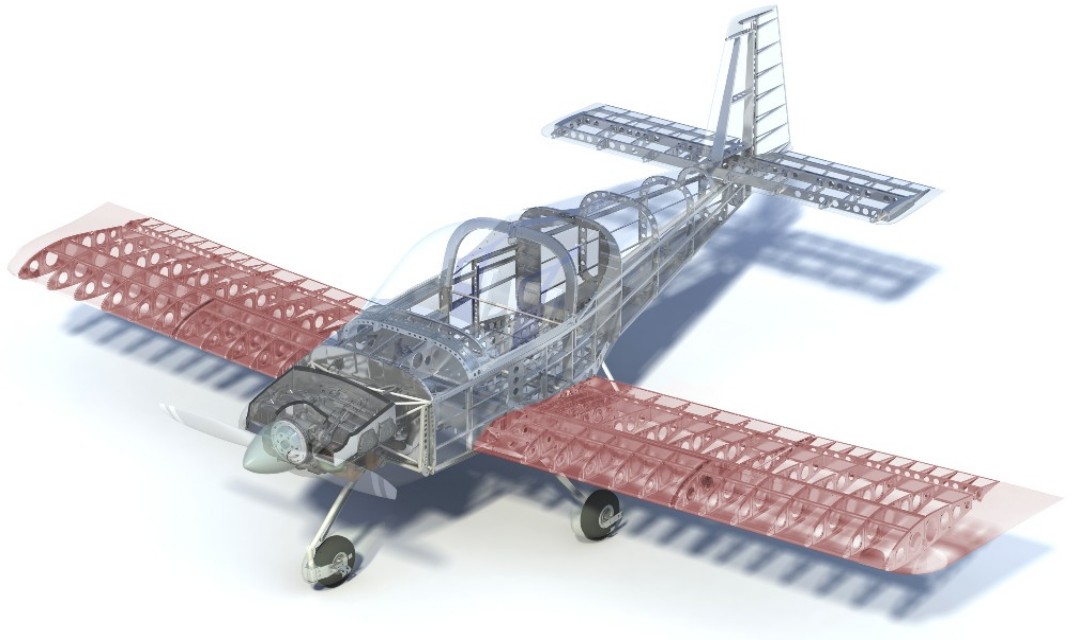

The big dream for us is one day to take off from

Israel on our self-constructed RV14a to cross the

ocean and land on one of the events you guys are

organizing in U.S. Yes it is possible, the navigation

path was already planned, and what left is just to

build the plane.

Guys, please give us some spiritual support. I hope

to shake hands with all of you very soon!

P.S: Will post our first actual status update in a day or two.

Cheers.

Roman & Dima

Last edited: