I'm pretty sure this is a 912iS only item...

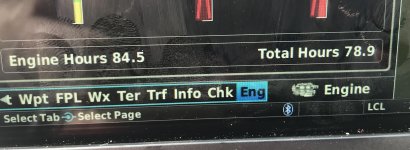

What's the difference between Hobbs vs. "ENGINE" time in the EMS? When I first energized my HDX system, the Hobbs showed zero, naturally, but there is a timer labeled "ENGINE", which showed 0.5 hours. I naturally assumed this was from the factory break-in period. Slowly, Hobbs has overtaken the ENGINE time. With over 100 hours on the engine, the Hobbs has gained about 45 minutes over the ENGING timer - now 112.5 on the Hobbs vs. 112.3 on ENGINE time. See attached screenshot of my EMS screen.

I've checked the Rotax manuals, floated this question to Dynon and on the Rotax Owner's forum, but no good answers, so, I'm reaching out to you iS engine guys with two questions:

1. Does anyone know the real meaning of ENGINE time?

2. How do Hobbs vs. ENGINE times compare on your aircraft?

What's the difference between Hobbs vs. "ENGINE" time in the EMS? When I first energized my HDX system, the Hobbs showed zero, naturally, but there is a timer labeled "ENGINE", which showed 0.5 hours. I naturally assumed this was from the factory break-in period. Slowly, Hobbs has overtaken the ENGINE time. With over 100 hours on the engine, the Hobbs has gained about 45 minutes over the ENGING timer - now 112.5 on the Hobbs vs. 112.3 on ENGINE time. See attached screenshot of my EMS screen.

I've checked the Rotax manuals, floated this question to Dynon and on the Rotax Owner's forum, but no good answers, so, I'm reaching out to you iS engine guys with two questions:

1. Does anyone know the real meaning of ENGINE time?

2. How do Hobbs vs. ENGINE times compare on your aircraft?