Thanks for asking Gary so here are the details:

The engine was bought NEW from Vans in 1998; 180hp Lycoming O360-A1A with LASAR electronic ignition. All cylinders were original/stock and never let us down (the valve wobble tests were all within limits too). Compressions were in the 71-74 lbs range, burning 1 quart of oil every 5 hours.

We ran a fixed (83) pitch Senenich for the first 2100 hours, typically running 2500rpm in cruise and peak EGT. We then switched to a Hartzell constant speed prop so we could keep up with Dan Checkoway and the rest of the

'Chino Power Squadron' (and it was also nice to have the C/S prop when flying formation with Stu McCurdy and company

We used Aeroshell 100w for the first 1000 or so hours then switched to Aeroshell 15/50w. We always kept the oil level at 6 quarts unless heading out for a long cross-country (7 quarts on the first leg outbound).

Oil Analysis was completed with

EVERY oil change, and the last 3-4 analysis have been showing steady increases in copper content; was 8ppm forever then creeping up to 12 ppm at 2400hrs and 16ppm at 2450 so I decided it was time (just putting off the inevitable otherwise).

2500hrs was a personal goal that we reached on the way home after a quick-trip to Las Vegas, and the engine was pulled the next day with 2501.1 TTSN.

Overhaul to factory new specs was completed by Exodus Air Service, located on Fox Field (WJF) airport, and they found nothing of significance after tearing down the engine. Crank was ground 0.003" as you could feel some slight 'grooving' on the main journal with your fingernail. We will be flying behind new,

ECI TiTan cylinders with thanks going to Tom & Katie Velvick for giving us their LOE '05 ECI discount certificate

We picked up the engine last Friday, and we hope to be back flying in the next two weeks.

Rosie

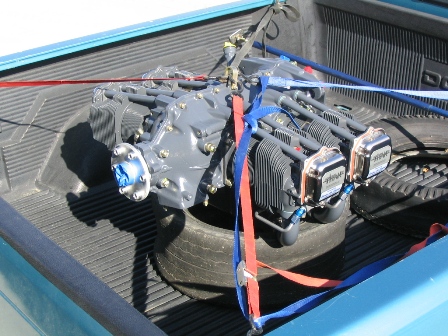

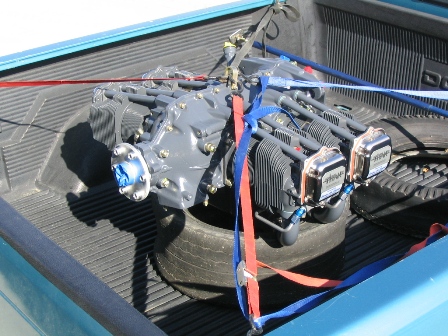

Here are some pictures on how I transported the engine from the engine shop, Exodus Air Service, to the hangar. I don't know if this is old-news but I came up with the tire idea when trying to get the engine to the shop. I ran it by the engine builder, and he said, 'No problem setting the motor in the tire'.

Here are some pictures on how I transported the engine from the engine shop, Exodus Air Service, to the hangar. I don't know if this is old-news but I came up with the tire idea when trying to get the engine to the shop. I ran it by the engine builder, and he said, 'No problem setting the motor in the tire'.

Rosie

Rosie