First, I am a flyer not a builder (RV 8). I bought my 8 January of 2007 when it was new, just having the required hours flown off. This was the 5th RV build of the builder ( who was an IAC competitor ) and was set up especially for IAC aerobatics with an inverted oil system, oil accumulator, both right and left tank flop tubes, steam gage g meter, CS prop powered by an AEIO 360 Lyc., duel pilot retaining belts and harness, and except for an early problem with the prop governor it has served me well now for just over 1000 hrs. My 8 has always been hangared and maintained by the same A&P (who has never offered any spontaneous advise related to my question). I have never seen any signs or symptoms of incipient failure and the question is....are there required or recommended replacements of the flop tubes and oil hoses based on time of use. I could find this info elsewhere but I respect the accumulated wisdom and experience of the VAF family of flyers and builders......so what say you? Thanks for your time and consideration. AWF

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

flop tubes and oil lines

- Thread starter A W Foltz

- Start date

Mikeyb

Well Known Member

One of my pet peeves. Just say no to flop tubes.

vansairforce.net

vansairforce.net

Flop Tube

I’ve opened my fuel tanks to remove sloshing. My Inspector pointed out that the flop lube, probably rubber, is subject to a life limit and therefor it would be a good time to replace it. So I went to the local hose supplier who stated that hose for fuel is not rubber. So if it’s not rubber...

[email protected]

Well Known Member

IF you can fly inverted and the engine still runs then the flop tube is still flopping. Probably not needing replacement, as far as the other oil/fuel lines, if they are rubber(black) Yes, there is a life time use of them. They get hard, brittle, and flaky inside.First, I am a flyer not a builder (RV 8). I bought my 8 January of 2007 when it was new, just having the required hours flown off. This was the 5th RV build of the builder ( who was an IAC competitor ) and was set up especially for IAC aerobatics with an inverted oil system, oil accumulator, both right and left tank flop tubes, steam gage g meter, CS prop powered by an AEIO 360 Lyc., duel pilot retaining belts and harness, and except for an early problem with the prop governor it has served me well now for just over 1000 hrs. My 8 has always been hangared and maintained by the same A&P (who has never offered any spontaneous advise related to my question). I have never seen any signs or symptoms of incipient failure and the question is....are there required or recommended replacements of the flop tubes and oil hoses based on time of use. I could find this info elsewhere but I respect the accumulated wisdom and experience of the VAF family of flyers and builders......so what say you? Thanks for your time and consideration. AWF

Also seen the inner liner get loose and close up the tube and making for a bad day and a hard to find problem.

Date of manufacture is usually printed somewhere on the line.

OR I would either call TS Flightlines and have Tom build you some new Teflon SS lines or build your own.

I won't use rubber lines for the obvious reasons of age and failure related problems.

I have no rubber lines in my life anymore

My luck varies FIXIT

I'm glad this thread came up. I am riveting the top skins on my right wing and about to start construction on the left. I had intended to install a flop tube in that tank but was dreading the additional modifications necessary to make it work. I read the threads @Mikeyb posted and have now decided to build on without. I have no plans for extended inverted flight. Just normal light stuff so it doesn't look like it's needed for my mission.

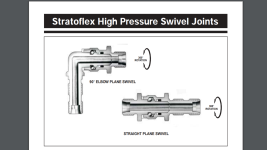

Flop tubes are generally rubber lined hose ( Aeroquip 701/Stratoflex 156 or the Summit/Jegs import inposter hose). So its replacement should be minimun of 5 years, max of 8. The additives in the fuel will break down the liner, to where there are black deposits in the filters. So why is this still the hose to use? Quite simply, teflon lined hose doesnt like too flex like a 701 hose. It has a 'memory' . It 'could' be used with a real live swivel fitting, but even those are rather stiff and not a free moving fitting. Even though the flop tube isnt under pressure, you still dont want the moving assembly to leak. LOL several years ago when we sponsored an RV airshow team, we played with the teflon hose idea and several swinging hose assembly ideas. Was quite involved, and it still didnt function as I wanted it to. So, we abandoned the idea hopeing that one day I'd have the time to come up with something that works well.I'm glad this thread came up. I am riveting the top skins on my right wing and about to start construction on the left. I had intended to install a flop tube in that tank but was dreading the additional modifications necessary to make it work. I read the threads @Mikeyb posted and have now decided to build on without. I have no plans for extended inverted flight. Just normal light stuff so it doesn't look like it's needed for my mission.

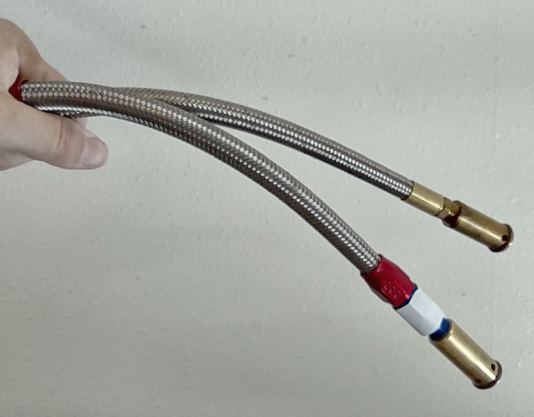

The hoses do get stiffer when old. Just replaced mine last year when I found the engine would quit when inverted below 1/2 tank of gas. Took this picture comparing the old (about 20 years after installed) and new hose.

That is the inverted orientation. They both bent about the same in the upright position as that is where it spent most of that 20 years.

That is the inverted orientation. They both bent about the same in the upright position as that is where it spent most of that 20 years.

Carl Froehlich

Well Known Member

If you must use a flop tube, replace it on only one tank. On the other tank buy the Van's premade screened pickup tube.

Lable the fuel selector for "this tank for inverted flight" or such.

Carl

Lable the fuel selector for "this tank for inverted flight" or such.

Carl

A flop tube is just barely short of worthless without an inverted oil system.

If you are doing maneuvers that require a flop tube to maintain fuel flow to keep the engine running, but you have nothing to keep the engine oil pump pumping oil, what good do you think you’re doing your engine?

If you are doing maneuvers that require a flop tube to maintain fuel flow to keep the engine running, but you have nothing to keep the engine oil pump pumping oil, what good do you think you’re doing your engine?

walkman

Well Known Member

So this is a timely thread and response.If you must use a flop tube, replace it on only one tank. On the other tank buy the Van's premade screened pickup tube.

Lable the fuel selector for "this tank for inverted flight" or such.

Carl

I'm also a flyer not a builder. I have a flop tube in one tank, not the other. Since I haven't maintained inverted flight long enough for the engine to quit on either tank I'm not sure which side my flop tube is in. However, its 20 years old this year and I have a replacement.

I have the wing root fairings off right now and can see there is a difference in where the fuel sender and fuel lines are in the wing root. The LHS has the fuel sender further back, and has a plate over where the fuel sender is on the RHS.

Which side is the flop tube? How can I tell?

I have to open one side up anyway to deal with a seep, fingers crossed its the same side. Also, I hate proseal lol

Flop tube will be connected at the leading edge of the wing. Normal fixed pickup is at the tank cover plate.So this is a timely thread and response.

I'm also a flyer not a builder. I have a flop tube in one tank, not the other. Since I haven't maintained inverted flight long enough for the engine to quit on either tank I'm not sure which side my flop tube is in. However, its 20 years old this year and I have a replacement.

I have the wing root fairings off right now and can see there is a difference in where the fuel sender and fuel lines are in the wing root. The LHS has the fuel sender further back, and has a plate over where the fuel sender is on the RHS.

Which side is the flop tube? How can I tell?

I have to open one side up anyway to deal with a seep, fingers crossed its the same side. Also, I hate proseal lol

Mikeyb

Well Known Member

The flop tube fuel line connects near the wing tip. The fuel sender is usually moved to the front of the tank outboard one bay and the blank cover plate is added on the flop tube side. you have to remove the tube and elbow together as they are safety wired together. There is an SB to install an anti rotation bracket inside the tank that might be in play as well that requires the new line fitting to be clocked identically to the one removed.So this is a timely thread and response.

I'm also a flyer not a builder. I have a flop tube in one tank, not the other. Since I haven't maintained inverted flight long enough for the engine to quit on either tank I'm not sure which side my flop tube is in. However, its 20 years old this year and I have a replacement.

I have the wing root fairings off right now and can see there is a difference in where the fuel sender and fuel lines are in the wing root. The LHS has the fuel sender further back, and has a plate over where the fuel sender is on the RHS.

Which side is the flop tube? How can I tell?

I have to open one side up anyway to deal with a seep, fingers crossed its the same side. Also, I hate proseal lol

Attachments

The QB wings for the Rocket have a flop tube in one side. Think about it….the kit is more than twenty years old….Flop tubes are generally rubber lined hose ( Aeroquip 701/Stratoflex 156 or the Summit/Jegs import inposter hose). So its replacement should be minimun of 5 years, max of 8. The additives in the fuel will break down the liner, to where there are black deposits in the filters. So why is this still the hose to use? Quite simply, teflon lined hose doesnt like too flex like a 701 hose. It has a 'memory' . It 'could' be used with a real live swivel fitting, but even those are rather stiff and not a free moving fitting. Even though the flop tube isnt under pressure, you still dont want the moving assembly to leak. LOL several years ago when we sponsored an RV airshow team, we played with the teflon hose idea and several swinging hose assembly ideas. Was quite involved, and it still didnt function as I wanted it to. So, we abandoned the idea hopeing that one day I'd have the time to come up with something that works well.

As much as I hate opening up sealed tanks, you can bet that old rubber hose is going to be replaced (by a new TS FLightlines Hose) before the wings get mounted!

I don’t know about anyone else, but I was aiming at the thread drift that was starting regarding just generically installing a flop tube.Ready-Fire-Aim

The OP clearly stated that his airplane has full inverted fuel and oil.

The most important issue with the rubber Aeroquip hose is that if the airplane is stored for a long period of time with low fuel level the hose will deteriorate more rapidly.

I think you mean near the wing leading edgeThe flop tube fuel line connects near the wing tip. The fuel sender is usually moved to the front of the tank outboard one bay and the blank cover plate is added on the flop tube side. you have to remove the tube and elbow together as they are safety wired together. There is an SB to install an anti rotation bracket inside the tank that might be in play as well that requires the new line fitting to be clocked identically to the one removed.

Bifft's pic is a good example of what happens to the rubber liner---even though you can see it--when exposed to fuel over time. Unfortunately, teflon is even stiffer. We even tried a convoluted liner--just the liner without the braid reinforcement, similar to a Indy Car fuel cell, and it still didnt flex like I wanted it to. Yes, I made it work in a mockup, but it took ALOT of end weight and it wasnt practical. Swivel joint is what I was leaning towards. WAYYY to expensive to use.I think you mean near the wing leading edge

Attachments

Last I looked, something like $600What is the price of one of those stratoflex swivel joints? If it saves having to get through all the sealant every 5/10 years to replace flop tubes, it may well be worth the one time expense.

JonJay

Well Known Member

Tom - if you could build a flop tube for $1k that didn’t need to be serviced for the assumed life of the airplane, you might have customers. Folks spend a lot more on a lot less in a build.Last I looked, something like $600

Looking around goggling their seems to be a multitude of possible options. I don’t have any idea how stiff the swivel joint would be, but the Parker brand is as reputable as can be. I suspect if it can handle several thousand pounds of positive pressure it ought to be able handle maybe one pound of negative pressure wile drawing fuel.

This particular one is rebuildable so it obviously comes apart and can be put back together, and quite possibly with lighter preload on the seals.

Just might be worth conducting an experiment, after all this is EXPERIMENTAL aviation

JonJay

Well Known Member

It would be more about the construction of the swivel, not the pressure. You also wouldn’t want to replace a rubber hose with a swivel with rubber seals.

I know you’re just throwing stuff at the wall but I bet Tom has already thought this out, hence, a $600 part!

I would want a system I didn’t need to service, which may not be possible, or even advisable.

I know you’re just throwing stuff at the wall but I bet Tom has already thought this out, hence, a $600 part!

I would want a system I didn’t need to service, which may not be possible, or even advisable.

similar idea. The Parkers are steel and heavy. I actually thought of the Stratoflex symetrics live swivels. And I was looking a AN versions , not NPT, but whatever has the least rotating resistance and sealing.It would be more about the construction of the swivel, not the pressure. You also wouldn’t want to replace a rubber hose with a swivel with rubber seals.

I know you’re just throwing stuff at the wall but I bet Tom has already thought this out, hence, a $600 part!

I would want a system I didn’t need to service, which may not be possible, or even advisable.

To All,

I expected meaningful input from VAF and I got it! Thanks to all that took the time to chime in, and to others, keep it coming if you have an opinion that adds too or even differs from what has already been said. I am gratified that for others who had lingering questions similar to mine........this thread has already made an impact on their build decisions. I certainly wish my builder had not installed flop tubes on both sides!

So I see some important maintenance changes to my 8 coming. Probably this winter. Between now and then I want to do a little experimenting. I want to run a tank down to about 1/3 and then go extended inverted to see if it will still draw fuel. If it does then I might try again at 1/4 which is about as low as I ever go under any circumstance. Like all fuel gauges, mine are suspect but my totalizer is quite accurate. Then while upright i will run the same tank to engine stall and change tanks, land and fill the "empty" tank and see how many gallons it takes. The number will be meaningful to me because long ago I ran this same tank dry, on purpose, just to see what my useful fuel # was. To my surprise it was almost exactly 21 gal. which is the rated total capacity. This should give me some idea of how my flop tube, on that side, is performing in its old age. Please realize this is only a data point of one and the data will only apply to my ship, and one tank, but it should satisfy some of my curiosity regarding flop tubes. If you are curious too I will share the data. Of course, I will be high up and near home base with a parachute on. AWF

I expected meaningful input from VAF and I got it! Thanks to all that took the time to chime in, and to others, keep it coming if you have an opinion that adds too or even differs from what has already been said. I am gratified that for others who had lingering questions similar to mine........this thread has already made an impact on their build decisions. I certainly wish my builder had not installed flop tubes on both sides!

So I see some important maintenance changes to my 8 coming. Probably this winter. Between now and then I want to do a little experimenting. I want to run a tank down to about 1/3 and then go extended inverted to see if it will still draw fuel. If it does then I might try again at 1/4 which is about as low as I ever go under any circumstance. Like all fuel gauges, mine are suspect but my totalizer is quite accurate. Then while upright i will run the same tank to engine stall and change tanks, land and fill the "empty" tank and see how many gallons it takes. The number will be meaningful to me because long ago I ran this same tank dry, on purpose, just to see what my useful fuel # was. To my surprise it was almost exactly 21 gal. which is the rated total capacity. This should give me some idea of how my flop tube, on that side, is performing in its old age. Please realize this is only a data point of one and the data will only apply to my ship, and one tank, but it should satisfy some of my curiosity regarding flop tubes. If you are curious too I will share the data. Of course, I will be high up and near home base with a parachute on. AWF

Freemasm

Well Known Member

Please keep in mind that most swivel connections not specific to fuel pick-up service will have a couple of "fatal flaws".

- Vast majority are designed/intended for pressure service. While the suction pressure at this joint would be a few inches of water (assuming clean fuel pick-ups), it's still a vacuum and would probably introduce air into your system (normal flight, less than ~1/2 full tanks). Long term effects would probably be realized in your fuel pumps.

- Many are not bubble tight but have allowable leakage limits. This will add to the above.

Hopefully Tom or someone else will come up with a solution. A hose change would be much easier than hardline retrofit.

- Vast majority are designed/intended for pressure service. While the suction pressure at this joint would be a few inches of water (assuming clean fuel pick-ups), it's still a vacuum and would probably introduce air into your system (normal flight, less than ~1/2 full tanks). Long term effects would probably be realized in your fuel pumps.

- Many are not bubble tight but have allowable leakage limits. This will add to the above.

Hopefully Tom or someone else will come up with a solution. A hose change would be much easier than hardline retrofit.

LOl----the issue I have is sealing the stem, but maintaining a very low rotational drag. You dont want it to leak and you want it to rotate very freely.Please keep in mind that most swivel connections not specific to fuel pick-up service will have a couple of "fatal flaws".

- Vast majority are designed/intended for pressure service. While the suction pressure at this joint would be a few inches of water (assuming clean fuel pick-ups), it's still a vacuum and would probably introduce air into your system (normal flight, less than ~1/2 full tanks). Long term effects would probably be realized in your fuel pumps.

- Many are not bubble tight but have allowable leakage limits. This will add to the above.

Hopefully Tom or someone else will come up with a solution. A hose change would be much easier than hardline retrofit.

Thanks for the input. not being a builder I appreciate the info regarding hose change vrs hard line retrofit. does you comment regarding drawing air, even in small amounts, will harm the fuel pump over time? I started a test of my 16 year old flop tubes Wednesday by flying inverted for 60 seconds, drawing 0.12 gal. from a tank holding only 6 gal. I had no indication from the engine that it wasn't getting all the fuel it needed.Please keep in mind that most swivel connections not specific to fuel pick-up service will have a couple of "fatal flaws".

- Vast majority are designed/intended for pressure service. While the suction pressure at this joint would be a few inches of water (assuming clean fuel pick-ups), it's still a vacuum and would probably introduce air into your system (normal flight, less than ~1/2 full tanks). Long term effects would probably be realized in your fuel pumps.

- Many are not bubble tight but have allowable leakage limits. This will add to the above.

Hopefully Tom or someone else will come up with a solution. A hose change would be much easier than hardline retrofit.

AWF