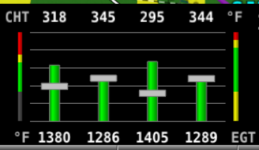

On my IO-360 with SDS, I have my #3 cylinder behaving a bit "out of family" with the other 3. This is not a new occurrence, it's been this way for over a thousand hours now, and it's not changing - quite stable - but I've run out of easy answers on what the story is. The engineer in me says there's a reason and I can't quit picking at it, like a kid with a scab on his knee.

Symptoms are that the #3 runs about 40-50 degrees cooler on CHT, and about 150 degrees warmer on EGT. I don't claim to be an engine expert but I do know my way around them pretty well - I know that it's NOT a spark plug, wire, or coil issue (having swapped them around back and forth), it's NOT a temp sensor issue (swapped those around too), and it's NOT a mixture issue as I have a GAMI spread between all the cylinders of either 0.0 or 0.1, depending on which day of the week I run the test and how carefully I do it. The SDS system allows me to individually trim the fuel flow to each cylinder, so dialing in the GAMI spread is easy. I see this temp spread on both 100LL and 93E10, both ROP and LOP, cruise and climb. The exhaust valve is not leaking as far as I can tell - 78/80 on that cylinder during my recent condition inspection and the borescope pictures of the exhaust valve look great. I burn one quart of oil in about 20 hours - so the rings are all good. I even lapped the exhaust valve in-situ a couple hundred hours ago, with no change.

The obvious answers have already been covered, which means it has to be something odd - which is where I turn to the brain trust here.

It's apparent that less combustion is occurring IN the cylinder, and more OUTSIDE the cylinder in the exhaust valve and pipe as compared to the others - which points to either an exhaust valve leak (none found) or perhaps the exhaust valve is opening too soon - which would only be possible if my exhaust valve pushrod is too long by some small amount and opening before the others. I have not pulled the rods and measured them but that's getting up pretty high on my "to-do" list now. Equally possible, and just as unlikely, is the the cam lobes for the other 3 cylinders are all worn down almost identically, but the engine makes no metal at 1640 hours so that's not supported by evidence.

Some of you gray-headed guys (like me) got any good ideas?

Symptoms are that the #3 runs about 40-50 degrees cooler on CHT, and about 150 degrees warmer on EGT. I don't claim to be an engine expert but I do know my way around them pretty well - I know that it's NOT a spark plug, wire, or coil issue (having swapped them around back and forth), it's NOT a temp sensor issue (swapped those around too), and it's NOT a mixture issue as I have a GAMI spread between all the cylinders of either 0.0 or 0.1, depending on which day of the week I run the test and how carefully I do it. The SDS system allows me to individually trim the fuel flow to each cylinder, so dialing in the GAMI spread is easy. I see this temp spread on both 100LL and 93E10, both ROP and LOP, cruise and climb. The exhaust valve is not leaking as far as I can tell - 78/80 on that cylinder during my recent condition inspection and the borescope pictures of the exhaust valve look great. I burn one quart of oil in about 20 hours - so the rings are all good. I even lapped the exhaust valve in-situ a couple hundred hours ago, with no change.

The obvious answers have already been covered, which means it has to be something odd - which is where I turn to the brain trust here.

It's apparent that less combustion is occurring IN the cylinder, and more OUTSIDE the cylinder in the exhaust valve and pipe as compared to the others - which points to either an exhaust valve leak (none found) or perhaps the exhaust valve is opening too soon - which would only be possible if my exhaust valve pushrod is too long by some small amount and opening before the others. I have not pulled the rods and measured them but that's getting up pretty high on my "to-do" list now. Equally possible, and just as unlikely, is the the cam lobes for the other 3 cylinders are all worn down almost identically, but the engine makes no metal at 1640 hours so that's not supported by evidence.

Some of you gray-headed guys (like me) got any good ideas?