Just a heads up for those that have a Hartzel propeller in long term storage or are considering buying a propeller thats been in storage.

Just a word of warning…

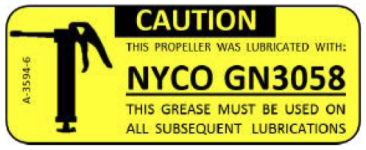

Hartzel told me when I bought my prop, that I had maybe two years before the grease separated and the seals would take a set. Then it would start slinging oil (separated from the grease).

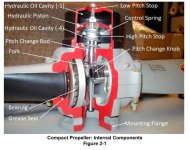

They were right…my prop sat in a heated garage for just over two years before it was put in service and then started slinging grease pretty bad in less than a hundred hours.

The fix is to have the prop disassembled and resealed. In my part of the country, that costs $1,200.

So, think twice about buying a prop and end up havIng it sit for years OR buying someone else’s prop thats been sitting for years without factoring in the reseal costs.

Just a word of warning…

Hartzel told me when I bought my prop, that I had maybe two years before the grease separated and the seals would take a set. Then it would start slinging oil (separated from the grease).

They were right…my prop sat in a heated garage for just over two years before it was put in service and then started slinging grease pretty bad in less than a hundred hours.

The fix is to have the prop disassembled and resealed. In my part of the country, that costs $1,200.

So, think twice about buying a prop and end up havIng it sit for years OR buying someone else’s prop thats been sitting for years without factoring in the reseal costs.

Last edited: