I want to put a compartment under the baggage area for tools -- that way I always have them with me but they aren't in the way. My plan is to put it between the left tunnel rib and the next rib towards the baggage door. Here is the area (note that this shows the right floor panel but I'd be modifying the left floor panel which is closer to the door).

A couple of notes. I don't plan to access this very often so I didn't want to mess with a hinge. The RV-10 is not aerobatic so I'm not worried about the lid having to withstand a lot of vertical force. But I do want to make sure the lid won't get damaged from a suitcase or similar being placed on top of it. I plan to line the entire compartment with foam (like a storage box) so that nothing can move around under the floor skin. I will also have carpet over this -- I will need to pull the carpet back to access the compartment. Therefore I think it is OK if the compartment is not perfectly flush.

Here is my plan so far and I'm looking for feedback:

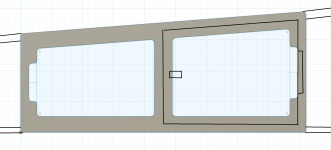

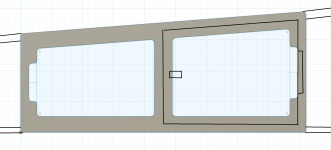

They gray piece will be a 0.05-thick aluminum backing plate that would go under the floor skin. At the top and bottom I plan to rivet it between the standard floor and the rib flanges. This will make the floor just a little bit uneven (by 0.05"), but I'm thinking with carpet it won't be noticeable. Note that I drew the flanges of the ribs to the left and right of the piece. The piece will not go all the way to the ends of the compartment, instead it will end approximately 3-4" prior to the front and back of the area. I will flush rivet the edges on the left and right of the drawing to the floor above.

I hand-drew the lid on the right side showing what one of the two lids would look like. Each lid will have a flush latch on the inside and a "under tab" on the outside. The tab will fit under the backing plate as shown in the picture. Most of the lid will be resting on the backing plate, except where the tab slides in.

This is my first attempt at any major modifications and I wanted feedback.

A couple of notes. I don't plan to access this very often so I didn't want to mess with a hinge. The RV-10 is not aerobatic so I'm not worried about the lid having to withstand a lot of vertical force. But I do want to make sure the lid won't get damaged from a suitcase or similar being placed on top of it. I plan to line the entire compartment with foam (like a storage box) so that nothing can move around under the floor skin. I will also have carpet over this -- I will need to pull the carpet back to access the compartment. Therefore I think it is OK if the compartment is not perfectly flush.

Here is my plan so far and I'm looking for feedback:

They gray piece will be a 0.05-thick aluminum backing plate that would go under the floor skin. At the top and bottom I plan to rivet it between the standard floor and the rib flanges. This will make the floor just a little bit uneven (by 0.05"), but I'm thinking with carpet it won't be noticeable. Note that I drew the flanges of the ribs to the left and right of the piece. The piece will not go all the way to the ends of the compartment, instead it will end approximately 3-4" prior to the front and back of the area. I will flush rivet the edges on the left and right of the drawing to the floor above.

I hand-drew the lid on the right side showing what one of the two lids would look like. Each lid will have a flush latch on the inside and a "under tab" on the outside. The tab will fit under the backing plate as shown in the picture. Most of the lid will be resting on the backing plate, except where the tab slides in.

This is my first attempt at any major modifications and I wanted feedback.

- I know the floor provides some structural support for the ribs and I wanted to make sure I don't compromise that. That's why I have this solid backing piece that rivets to the ribs and has the center support. I may want to put some additional strength under that center support that divides the two compartments.

- I definitely need to reinforce the lids in some way. In the plans, there are some stiffeners under the floor in this area, but I don't think that's enough for this lid. Because the lid is not attached anywhere it won't have any tensile strength.