jimkwalton

Active Member

Cruising along at 6,500 MSL, 23 inches, 22 RPM, lean of peak at 8 GPH when all of a sudden the engine starts buzzing, partial power loss! Change tanks, mixture full rich, boost pump on. No change.

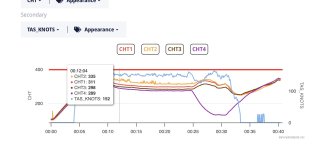

Look at #4 EGT has dropped to 400° and going down. CHT starts dropping. I still have control of the engine just partial loss of power.

Stayed high, landed at destination since it was next to closest airport.

Also as I entered the pattern (high of course) the engine power returned to normal.

Downloaded flight data. It showed #4 cylinder EGT/CHT drop for 6 minutes then return to normal. Buzzing sound from engine.

Side note, this happened to #2 cylinder about 3-4 months ago for less than a minute.

Stuck exhaust valve? Debris in fuel line?

IO-390 in my RV14 around 380 tach time from new engine. Cold engine start has a short “morning sickness” on start until. I aggressively lean after start.

Any thoughts?

Look at #4 EGT has dropped to 400° and going down. CHT starts dropping. I still have control of the engine just partial loss of power.

Stayed high, landed at destination since it was next to closest airport.

Also as I entered the pattern (high of course) the engine power returned to normal.

Downloaded flight data. It showed #4 cylinder EGT/CHT drop for 6 minutes then return to normal. Buzzing sound from engine.

Side note, this happened to #2 cylinder about 3-4 months ago for less than a minute.

Stuck exhaust valve? Debris in fuel line?

IO-390 in my RV14 around 380 tach time from new engine. Cold engine start has a short “morning sickness” on start until. I aggressively lean after start.

Any thoughts?