pilot28906

Well Known Member

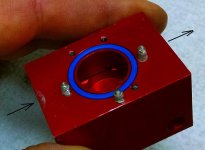

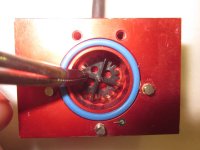

I have my red cube mounted directly to the spider divider on the engine with no cube bracket. I am at about 80 hours on the airplane and have had no problems with the red cube. It reads correctly and I am very happy with it. My question is are there others who have mounted in the same location without the red cube bracket who have had any trouble with this set up? I have the old style red cube mount but have not been able to make the fit work. I would like to see how many hours others have had with this setup and if they have had any problems with not using the red cube bracket mount.

Thanks

Thanks