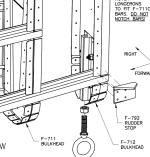

After the hurricane blasted through the north of this area I noticed that the rear Tie-down of my RV6A was bent and that the F-612 bulkhead was torn slightly. Winds were about 40-50 knots in this area. Something I'll have to fix unfortunately. The way the Tie-down was installed by the builder was attaching a bracket with a Tie-down ring welded to it and bolted to the F-612 bulkhead. The way it is now, force is torqued at almost a 45 degree angle angle to the bulkhead, the bottom of the bulkhead tore where the plate attaches.

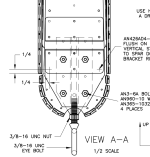

I've read some post where people mention the RV7 design is better, but I can find any pictures to see what this is. Does anyone else have any other solutions they have used that have worked out well?

I've read some post where people mention the RV7 design is better, but I can find any pictures to see what this is. Does anyone else have any other solutions they have used that have worked out well?