Apologize in advance if this has been covered before but I did search the forums.

Do it right or do it twice!

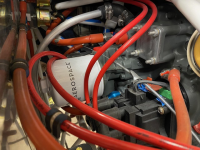

I hung my engine and realized that I have the older style accessory case with only 1 Oil Pressure port. In order to install the 45* restrictor fitting I have to remove the engine from the mount. Fortunately I haven't connected any wires or started on the baffling. The instructions state to have the fitting point 45* downward and 45* outward. Can someone please post a few pictures of how the Oil pressure supply hose is routed past the motor mount and Mag? I am going to be installing P-MAGS.

Also, I think that this is the only fitting that needs to be installed before the engine is installed, but if I am missing something else please let me know.

Thanks in advance.

Do it right or do it twice!

I hung my engine and realized that I have the older style accessory case with only 1 Oil Pressure port. In order to install the 45* restrictor fitting I have to remove the engine from the mount. Fortunately I haven't connected any wires or started on the baffling. The instructions state to have the fitting point 45* downward and 45* outward. Can someone please post a few pictures of how the Oil pressure supply hose is routed past the motor mount and Mag? I am going to be installing P-MAGS.

Also, I think that this is the only fitting that needs to be installed before the engine is installed, but if I am missing something else please let me know.

Thanks in advance.