You should use a straight mineral oil, not a multi viscosity oil during break in.The Lycoming manual just says mineral oil for the first 50 hours. But, which one? AeroShell 100 SAE 50 or SAE 40? Or, some other?

I used aeroshell 100. When the air temperature is in the 40 degF range, the engine turns over more sluggishly than when it is in the 70 degF range. I also found out that if I rotate the prop for a couple of turns during preflight, then the engine turns over easier even when it is cold outside.I found it in Appendix A of the installation manual. from 30-90F use 40W, above 60F use 50W. So, since I'll probably start it for the first time this winter at temps around 30-50F, I'll begin with 40W.

I always use Phillips 20W-50M.The Lycoming manual just says mineral oil for the first 50 hours. But, which one? AeroShell 100 SAE 50 or SAE 40? Or, some other?

Agreed, single weight seems to hold contaminants better in suspension.Lycoming suggests single weight mineral oil. I dont think you want to argue with them if there's a problem... As others have said, the usual is AeroShell Oil 100 (not 100 W).

Lycoming suggests single weight mineral oil. I dont think you want to argue with them if there's a problem... As others have said, the usual is AeroShell Oil 100 (not 100 W).

Please post the Lycoming document that supports your position.Agreed, single weight seems to hold contaminants better in suspension.

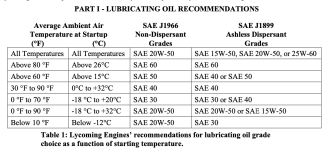

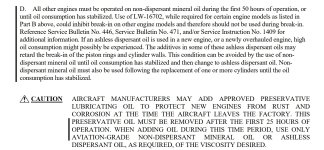

The above is Table 1 of Part I of the SI. This Part I is for the normal operation of the engine, whether operational or when bringing an engine out of storage with preservative oil. Not the break-in operation. That is Part II further on in the report. But to be fair Part II insists on non AD oil and then goes on to explain the issues that result by breaking in with AD oil. To be fair they do no distinguish between single weight (like 100) or multi-weight non-dispersant oil (like the Philips 20W-50 type M). Here is Part II section D:Please post the Lycoming document that supports your position.

Lycoming Service Instruction 1014 lists the recommended lubrication oil and includes multi-weight oil.

View attachment 70817

Please post the Lycoming document that supports your position.

First 2,200 hours, I ran mostly multi-weight 15W-50. Did run one case of FREE Exxon 20W-50 and one oil change of straight 100W. At 2,200 hours, I pulled four cylinders because of worn valve guides. (failed the Lycoming wobble test) Compressions were in the high 60's low 70's. Was using one quart of oil every 6 to 7 hours.Based on subjective observation and since nobody can explain why the IO-390 develops sticky valves on Cyl 2 the majority of the time here goes. Even an expert like Mike Busch feels too cold of CHT's contribute to sticky valves. The only issue is cylinder 2 in the majority of cases is the hottest cylinder in an IO-390. This is my story and for now I'm sticking to it.

For the first 200 hours of operation, I ran 100W and after break-in 100W plus. (Florida mostly and Ohio summers) Around 25 hours my oil would become very dark and was taught to change on condition which I did. Sometimes less than 25 hours. Every oil change Blackstone would give me an oil analysis and typically around 2,500 ppm lead. Other numbers looked great. A friend suggested a multi-weight (20-50) and thought that might help. It certainly seemed to and now was getting ~ 40 hours at the same level of darkness. Blackstone confirmed still seeing ~ 2,500 ppm lead and thought all was good. After the third oil change time for a conditional and my borescope showed lots of black particles around my valves, some fairly sticky. Cylinder 2 was the worst of the 4. Another oil change and inspection and could see these particles getting worse. Not knowing what to think went back to 100W plus. Next oil change less particles. As of 500 hours the particles and gue have not returned. Was the 20-50 holding less particles in solution and that is why it was looking cleaner? Being a multi-weight did that help the blow-by and that is why it looked cleaner? I had 2 long cross countries and that did not seem to help the 100W plus oil get darker less quickly, thinking I was getting blow-by as the oil was warming up. It "seemed" the majority of the sticky valve 390's 20-50 was being used, or was 20-50 just being used the majority of the time in 390's? Again, this is all very subjective on my part.