gmcjetpilot

Well Known Member

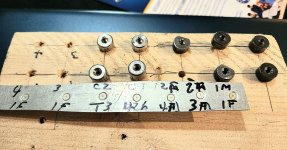

So I know the CAT 436-3 is Cleaveland tools. It is lazer etched, shiny polished. I assume this is the spring back die.

I have a second that looks identical to the CAt 426-3 but stamped in it "T3". It is a stamp not laser etched.

I can say they both produce similarnice dimples in sample 0.032 clad 2024-T3. The T3 may be a tad more? May be my imagination. Hard to tell and rivets have tolerances as well. Both are #40 pilots.

I bought these over a decade ago and forgot what was what.

What is the T3? I vaguely recall is there is a TANK dimple die that goes a bit deeper for sealant?

What do you think of Cleveland dimple dies. They are top quality in appearance. I have 2 other dies that are steel not polished but produce acceptable dimples with similar depth, may be a bit less depth, small surface aberrations round dimple? The quality of the CAT 426.-3 and T3 dimples are better. That is why I bought them, but again what is a "T3"?

I have a second that looks identical to the CAt 426-3 but stamped in it "T3". It is a stamp not laser etched.

I can say they both produce similarnice dimples in sample 0.032 clad 2024-T3. The T3 may be a tad more? May be my imagination. Hard to tell and rivets have tolerances as well. Both are #40 pilots.

I bought these over a decade ago and forgot what was what.

What is the T3? I vaguely recall is there is a TANK dimple die that goes a bit deeper for sealant?

What do you think of Cleveland dimple dies. They are top quality in appearance. I have 2 other dies that are steel not polished but produce acceptable dimples with similar depth, may be a bit less depth, small surface aberrations round dimple? The quality of the CAT 426.-3 and T3 dimples are better. That is why I bought them, but again what is a "T3"?

Attachments

Last edited: