scsmith

Well Known Member

As I've hinted for the past few months, I am now finally ready to announce the introduction of two NEW different ram-air intake systems. Both share some common design features of the old Rod Bower ram-air intake systems, but both also offer improvements. Both use a K&N RU-2510 conical air filter and fit the RSA-5 fuel servo and (I believe FM-150 also). Mounting to other fuel servos or carburetors can be accommodated by special order. Like the Bower system, both attach to the fuel servo by means of a worm-type hose clamp on the base neck of the K&N filter clamping to an inlet adapter ring that mounts to the fuel servo. This attachment provides some flexibility to account for engine movement. Additional flexibility is provided at the connection sleeve to the intake tube in the cowl. Also similar to the Bower system, the filter canister occupies some volume up front that probably requires some alteration of the cowl -- My RV-8 ram-air intake is smile shaped and just naturally blends into the cowl in a way that creates enough clearance for the filter canister. I have not tried it, but I suspect that a modest bulge would be required for clearance if you have an otherwise smooth Vans cowl. With the extra length of the Sam James and Showplanes cowls, it might fit without alteration.

The first system will be called Type 1, and is fairly similar in most respects to the original Rod Bower system, except that rather than use reed valves to draw alternate intake air from the lower cowl area, it uses a snorkel to pull alternate intake air from the #2 cylinder cooling intake ramp. Here is a picture of the prototype installed on my RV-8 (it has been in service for 15 years).

You can see that I use a neoprene foam material to make a connection sleeve to the intake tube in the cowl.

The overall length of the Type-1 intake from fuel servo face to the front of the alternate air valve is 6".

There are two advantages of this system: first, it draws alternate air from the cooling ramp which is at a fairly high pressure (almost full ram pressure) and is cool, rather than intaking hot air from the lower cowl. The other advantage (compared to the Type 2 system) is that the alternate air source is separate from the primary ram-air intake source, so if by bizarre chance a bird got lodged in your ram-air intake, you could switch to alternate air. A disadvantage of this system is that the alternate air pathway is not closed off when used in full ram-intake mode, so there may be a small amount of 'back flow' through the filter and out the intake snorkel, reducing the ram air pressure. I believe this is very small, but this is the issue that I wanted to address with the type 2 system.

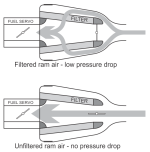

The Type 2 system uses a different filter canister that incorporates an annular bypass duct around the alternate air valve and into the filter canister. The operation is shown schematically here:

The principal advantage of this design is that full ram pressure is supplied in both ram-intake mode and alternate air mode, and no pressure is lost through back flow through the filter. One disadvantage of this design is that since both modes use the same intake, in the remote chance that a bird or large snow ball obstructs your intake, you won't get any intake air. If this unlikely scenario concerns you, you could install a spring-hinged blow-in door in the filter canister, similar to those typically installed in filtered air boxes.

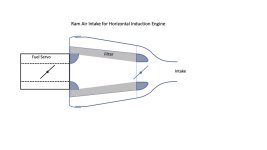

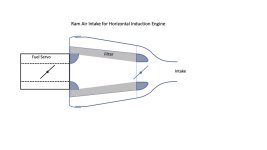

The alternate air valve with the annular bypass requires that the canister be somewhat longer. The prototype, shown below, is currently 8.75" long from the fuel servo face to the front of the intake tube, but can be trimmed to 8.5" if the intake tube is trimmed (trim line shown in red) . The tooling for the filter canister is currently being modified to reduce the length by almost 3/4", so the length will be approximately 7.75" on the production model.

The length makes this unit somewhat challenging to install in a standard Vans cowl. My RV-8 cowl has a smile-shaped intake similar to a P-51 Mustang intake, with a transition from the smile shape to the 3" round tube over about 2.5". That transition uses up enough length that I can not install the Type 2 system in my cowl. If you have a simple round intake tube (like a Sam James cowl intake) then I think you could install the Type 2 intake system in a Vans cowl. If you have a longer Sam James or Showplanes cowl, then there should be plenty of length available to install the Type 2 intake system.

Here is a picture of all the goodies that come assembled on the Type 2 intake system:

The alternate air valve with bypass duct is 3D-printed from plastic. The first three are nylon, which is nice and ductile and has good high-temperature properties, but it has a somewhat granular surface finish that is difficult to sand smooth. For future parts, I am considering switching to ABS. I think it will still be ductile enough and can be sanded smooth.

Product details questions, any special features desired (e.g. fitting to a M-S HA-6 carb or an FM-200, installing a spring-hinged blow-in door, kit option details, etc) Please comment in this thread or contact me here through PM "Conversation".

Ordering and pricing:

You can order through HP Aircraft (an advertiser here on VAF)

Both the Type 1 and Type 2 systems can be ordered fully assembled or in kit form, where you do some of the final assembly, and save some money.

The price I am offering these at is driven by the costs of the parts that I have to have made or buy off the shelf, plus my labor time in making the fiberglass parts and assembling the pieces.

The Type 1 Intake System is $1000 fully assembled with the snorkel transition piece bonded in place, but you supply the snorkel.

The Type 2 Intake System is $1150, fully assembled.

Options/extras:

Subtract $250 for either system in kit form, but please discuss with me first what assembly tasks you will have to perform.

I have a limited supply of 1/4" neoprene foam material (like a mouse pad or wet suit) that can be used to make a intake coupling sleeve. Price TBD

I could prototype a spring-hinge blow-in door for you, Price TBD

Since the prototype Type 2 system (pictured above) is about 3/4" longer than the production model will be, I will sell that one at a discount. $1000. But please have some degree of confidence that your cowling can accommodate the length.

Lead Times:

I have a limited quantity of the various bits that get assembled, and I will make the fiberglass canister parts to order. So lead time will be somewhat variable and dependent on the responsiveness of my suppliers. It took a month to get five throttle shafts for the alternate air valve from my machinist last time! I can't afford to support much inventory, so I will order parts as needed depending on how many orders I get. Some parts have significant quantity discounts, some don't.

The first system will be called Type 1, and is fairly similar in most respects to the original Rod Bower system, except that rather than use reed valves to draw alternate intake air from the lower cowl area, it uses a snorkel to pull alternate intake air from the #2 cylinder cooling intake ramp. Here is a picture of the prototype installed on my RV-8 (it has been in service for 15 years).

You can see that I use a neoprene foam material to make a connection sleeve to the intake tube in the cowl.

The overall length of the Type-1 intake from fuel servo face to the front of the alternate air valve is 6".

There are two advantages of this system: first, it draws alternate air from the cooling ramp which is at a fairly high pressure (almost full ram pressure) and is cool, rather than intaking hot air from the lower cowl. The other advantage (compared to the Type 2 system) is that the alternate air source is separate from the primary ram-air intake source, so if by bizarre chance a bird got lodged in your ram-air intake, you could switch to alternate air. A disadvantage of this system is that the alternate air pathway is not closed off when used in full ram-intake mode, so there may be a small amount of 'back flow' through the filter and out the intake snorkel, reducing the ram air pressure. I believe this is very small, but this is the issue that I wanted to address with the type 2 system.

The Type 2 system uses a different filter canister that incorporates an annular bypass duct around the alternate air valve and into the filter canister. The operation is shown schematically here:

The principal advantage of this design is that full ram pressure is supplied in both ram-intake mode and alternate air mode, and no pressure is lost through back flow through the filter. One disadvantage of this design is that since both modes use the same intake, in the remote chance that a bird or large snow ball obstructs your intake, you won't get any intake air. If this unlikely scenario concerns you, you could install a spring-hinged blow-in door in the filter canister, similar to those typically installed in filtered air boxes.

The alternate air valve with the annular bypass requires that the canister be somewhat longer. The prototype, shown below, is currently 8.75" long from the fuel servo face to the front of the intake tube, but can be trimmed to 8.5" if the intake tube is trimmed (trim line shown in red) . The tooling for the filter canister is currently being modified to reduce the length by almost 3/4", so the length will be approximately 7.75" on the production model.

The length makes this unit somewhat challenging to install in a standard Vans cowl. My RV-8 cowl has a smile-shaped intake similar to a P-51 Mustang intake, with a transition from the smile shape to the 3" round tube over about 2.5". That transition uses up enough length that I can not install the Type 2 system in my cowl. If you have a simple round intake tube (like a Sam James cowl intake) then I think you could install the Type 2 intake system in a Vans cowl. If you have a longer Sam James or Showplanes cowl, then there should be plenty of length available to install the Type 2 intake system.

Here is a picture of all the goodies that come assembled on the Type 2 intake system:

The alternate air valve with bypass duct is 3D-printed from plastic. The first three are nylon, which is nice and ductile and has good high-temperature properties, but it has a somewhat granular surface finish that is difficult to sand smooth. For future parts, I am considering switching to ABS. I think it will still be ductile enough and can be sanded smooth.

Product details questions, any special features desired (e.g. fitting to a M-S HA-6 carb or an FM-200, installing a spring-hinged blow-in door, kit option details, etc) Please comment in this thread or contact me here through PM "Conversation".

Ordering and pricing:

You can order through HP Aircraft (an advertiser here on VAF)

Both the Type 1 and Type 2 systems can be ordered fully assembled or in kit form, where you do some of the final assembly, and save some money.

The price I am offering these at is driven by the costs of the parts that I have to have made or buy off the shelf, plus my labor time in making the fiberglass parts and assembling the pieces.

The Type 1 Intake System is $1000 fully assembled with the snorkel transition piece bonded in place, but you supply the snorkel.

The Type 2 Intake System is $1150, fully assembled.

Options/extras:

Subtract $250 for either system in kit form, but please discuss with me first what assembly tasks you will have to perform.

I have a limited supply of 1/4" neoprene foam material (like a mouse pad or wet suit) that can be used to make a intake coupling sleeve. Price TBD

I could prototype a spring-hinge blow-in door for you, Price TBD

Since the prototype Type 2 system (pictured above) is about 3/4" longer than the production model will be, I will sell that one at a discount. $1000. But please have some degree of confidence that your cowling can accommodate the length.

Lead Times:

I have a limited quantity of the various bits that get assembled, and I will make the fiberglass canister parts to order. So lead time will be somewhat variable and dependent on the responsiveness of my suppliers. It took a month to get five throttle shafts for the alternate air valve from my machinist last time! I can't afford to support much inventory, so I will order parts as needed depending on how many orders I get. Some parts have significant quantity discounts, some don't.

Last edited: