woodsideraff

Well Known Member

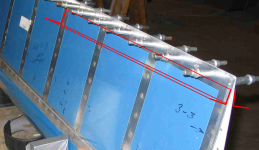

We are ready to drill the elevator pushrod attachment and noticed about 0.15" deviation from a straight line at the right elevator inboard edge.

Vans assures me that this is totally acceptable. Nevertheless, I'm curious to know what other builders are obtaining.

Vans assures me that this is totally acceptable. Nevertheless, I'm curious to know what other builders are obtaining.

Last edited: