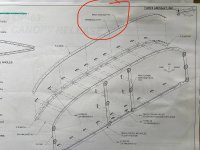

On page 35-13 the instructions call to countersink the 0.032” thick F-01467B Instrument Panel Flange Doubler.

Has anyone dimpled this instead? (Including dimpling the underlying flange parts?)

I’m wondering why they would call to countersink this part.

I do vaguely recall this being discussed, but I apologise I can’t find the thread.

Has anyone dimpled this instead? (Including dimpling the underlying flange parts?)

I’m wondering why they would call to countersink this part.

I do vaguely recall this being discussed, but I apologise I can’t find the thread.

Attachments

Last edited: