HFS

Well Known Member

This is one of those issues where everybody has their own, "best" way of doing this - this is just mine ...

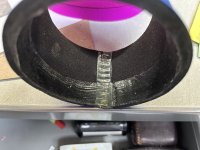

I use as thick a "coated" neoprene wetsuit material I can find (6.5mm is what I am using now), develop a pattern, join the "butt" ends with wetsuit adhesive; and, here is where the "magic" is - cross stitch the joint with Kevlar thread (I dare you to break it) and then "seal" it with clear silicone.

Also, you may want one of the overrunning contact surfaces to be non-skid, to assist in position maintenance when in use; so, I also apply a thin, uniform layer of clear silicone to the contact area of the sleeve.

I also modify a worm drive hose clamp to a wider body width to better distribute the bearing load on the soft sleeve material when securing it to its attendant inlet ring (if so equipped).

HFS

I use as thick a "coated" neoprene wetsuit material I can find (6.5mm is what I am using now), develop a pattern, join the "butt" ends with wetsuit adhesive; and, here is where the "magic" is - cross stitch the joint with Kevlar thread (I dare you to break it) and then "seal" it with clear silicone.

Also, you may want one of the overrunning contact surfaces to be non-skid, to assist in position maintenance when in use; so, I also apply a thin, uniform layer of clear silicone to the contact area of the sleeve.

I also modify a worm drive hose clamp to a wider body width to better distribute the bearing load on the soft sleeve material when securing it to its attendant inlet ring (if so equipped).

HFS