NavyS3BNFO

Well Known Member

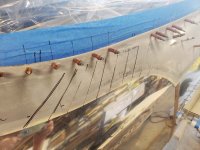

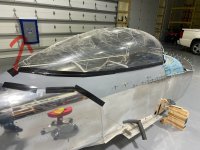

I'm in the process of fitting the skirt to the canopy and I have some pretty big gaps near the back where it curves up the fuselage. I've looked at some of the other threads and it looks like some builders have just cut it off and layed up new fiberglass. I'm one of those "avoid fiberglass work at all costs" guys so I'm polling the collective to see if there is anything else I should try before I commit to major surgery. The rest of the skirt fits pretty well.