PilotjohnS

Well Known Member

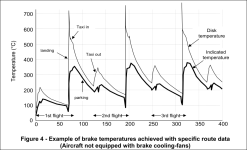

I want to put a thermal couple on each brake caliper. With the g3X system, I can have a readout of brake temps using the aux temp sensor input on the GEA24.

What location on the brake caliper is best? I plan to just attach with JB weld.

What location on the brake caliper is best? I plan to just attach with JB weld.