On the runup pad, the usual 40 drop was more like 100 on one of them. Not rough, not ugly, just excessive. No problem, only going up to screw around anyway, so let's test.

Set up 65% cruise, lean just short of rough. Turn on EFIS logging. Run on one ignition for a bit, then both for a moment, then the other ignition, the one with the abnormal drop. Catch a few barrel rolls, then back to base.

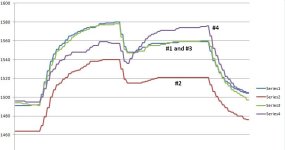

At home, download the memory stick, find the flight segment, dump the single ignition EGTs into Excel and plot them. Look at #4 when running on the top plugs, right side of the plot.

Today, back to the airport, pull the cowl and plenum cover. Pop the plug cap off #4, look inside the boot. The little C-shaped spring which clamps the tip of the spark plug was broken, so it had been chaffing and fretting and creating rusty dust, the result being high resistance.

This is a new plug terminal. The spring is the black part.

Ain't science grand?

Set up 65% cruise, lean just short of rough. Turn on EFIS logging. Run on one ignition for a bit, then both for a moment, then the other ignition, the one with the abnormal drop. Catch a few barrel rolls, then back to base.

At home, download the memory stick, find the flight segment, dump the single ignition EGTs into Excel and plot them. Look at #4 when running on the top plugs, right side of the plot.

Today, back to the airport, pull the cowl and plenum cover. Pop the plug cap off #4, look inside the boot. The little C-shaped spring which clamps the tip of the spark plug was broken, so it had been chaffing and fretting and creating rusty dust, the result being high resistance.

This is a new plug terminal. The spring is the black part.

Ain't science grand?

Last edited: