So I recently received my GRT HXr from Steinair, and it's time to start thinking about installing it.

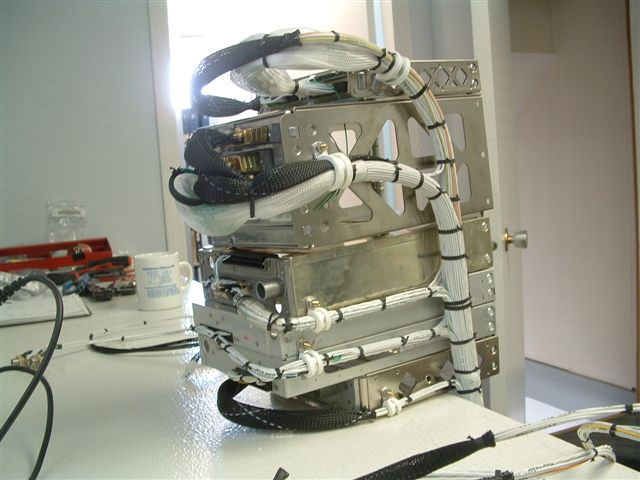

First off, here's what she currently looks like:

Vacuum/Electric 6 pack, an ADI Pilot I and an ICOM A210. The wiring is nice and safe for a VFR only airplane, but it's a total rats nest, so most of it has to go.

I'll be installing the HXr and related bits, EIS, engine sensors, new fuse busses, a B&C 8 amp backup alternator, a small brownout battery, a GTX327 transponder and a russian clock like Vlad's (an airplane has to have at least one mechanical dial)

Here's what I've come up so far for a panel design:

It shows an SL30, but that's the model I had, pretend it's an A210. I'll keep using the A210 intercom until messing with radios later (see below).

The 3.125" cutout is for the clock (not correct but close enough for planning, haven't drawn it in CAD yet). The hole under that is for the mag/starter key switch (I've already got it, might as well use it, plus I think the key is a good extra way to make sure the mags are cold, I keep the key in the canopy lock when out of the airplane, nice visual check). The switch next to that will switch the GRT tach drive from Left to Right mag for mag checks.

The switches (left to right) are:

Starting/running:

Master, main alt, fuel pump, avionics bus (will be DPDT to allow for turning the avionics on with and without the brownout battery)

Emergencies/problems:

E-buss feed (from batt), Backup alt field, Autopilot servos off

Lighting:

Strobe, nav, taxi, ldg, interior

Then there are two alt field breakers

I'm putting the EIS on the panel for now just for passenger/co-pilot comfort/use but it would go away if I ever put in a second EFIS screen.

The plan right now will be to fly like that for a while till recovering the bank account and getting used to the GRT stuff, then add an SL30, 430W, 480, 530W or something else to start my instrument training. By/At that point I will have added backup attitude/altitude/airspeed information in the form of either:

The GRT android extender a tablet and probably a second ADAHRS (really likely w/o the second ADAHRS, somewhat less with)

another HXr screen and second ADAHRS (not all that likely)

A Dynon D10A or similar small EFIS (ebay is my friend)

The panel is designed such that the EIS cutout won't interfere with making a bigger cutout to add another HXr or other big screen if the time came wiout making a new panel.

The throttle, mixture, carb heat and flap switch will stay on the usual little subpanel below the main panel, no changes there (except moving the flap switch to between the throttle and mixture)

Headset jacks will go behind the seats somewhere.

Thoughts?

Part two will be ripping the current panel out, re-building some of the subpanel (to move the radios to the center requires filling one hole and making another, and the sub panel wasn't built nearly as nice as the rest of the plane)

First off, here's what she currently looks like:

Vacuum/Electric 6 pack, an ADI Pilot I and an ICOM A210. The wiring is nice and safe for a VFR only airplane, but it's a total rats nest, so most of it has to go.

I'll be installing the HXr and related bits, EIS, engine sensors, new fuse busses, a B&C 8 amp backup alternator, a small brownout battery, a GTX327 transponder and a russian clock like Vlad's (an airplane has to have at least one mechanical dial)

Here's what I've come up so far for a panel design:

It shows an SL30, but that's the model I had, pretend it's an A210. I'll keep using the A210 intercom until messing with radios later (see below).

The 3.125" cutout is for the clock (not correct but close enough for planning, haven't drawn it in CAD yet). The hole under that is for the mag/starter key switch (I've already got it, might as well use it, plus I think the key is a good extra way to make sure the mags are cold, I keep the key in the canopy lock when out of the airplane, nice visual check). The switch next to that will switch the GRT tach drive from Left to Right mag for mag checks.

The switches (left to right) are:

Starting/running:

Master, main alt, fuel pump, avionics bus (will be DPDT to allow for turning the avionics on with and without the brownout battery)

Emergencies/problems:

E-buss feed (from batt), Backup alt field, Autopilot servos off

Lighting:

Strobe, nav, taxi, ldg, interior

Then there are two alt field breakers

I'm putting the EIS on the panel for now just for passenger/co-pilot comfort/use but it would go away if I ever put in a second EFIS screen.

The plan right now will be to fly like that for a while till recovering the bank account and getting used to the GRT stuff, then add an SL30, 430W, 480, 530W or something else to start my instrument training. By/At that point I will have added backup attitude/altitude/airspeed information in the form of either:

The GRT android extender a tablet and probably a second ADAHRS (really likely w/o the second ADAHRS, somewhat less with)

another HXr screen and second ADAHRS (not all that likely)

A Dynon D10A or similar small EFIS (ebay is my friend)

The panel is designed such that the EIS cutout won't interfere with making a bigger cutout to add another HXr or other big screen if the time came wiout making a new panel.

The throttle, mixture, carb heat and flap switch will stay on the usual little subpanel below the main panel, no changes there (except moving the flap switch to between the throttle and mixture)

Headset jacks will go behind the seats somewhere.

Thoughts?

Part two will be ripping the current panel out, re-building some of the subpanel (to move the radios to the center requires filling one hole and making another, and the sub panel wasn't built nearly as nice as the rest of the plane)

Last edited: