hydroguy2

Well Known Member

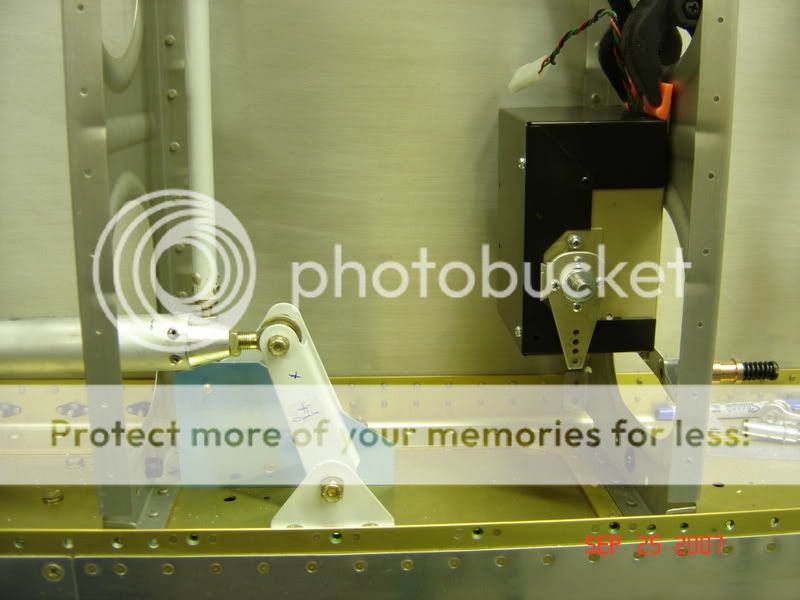

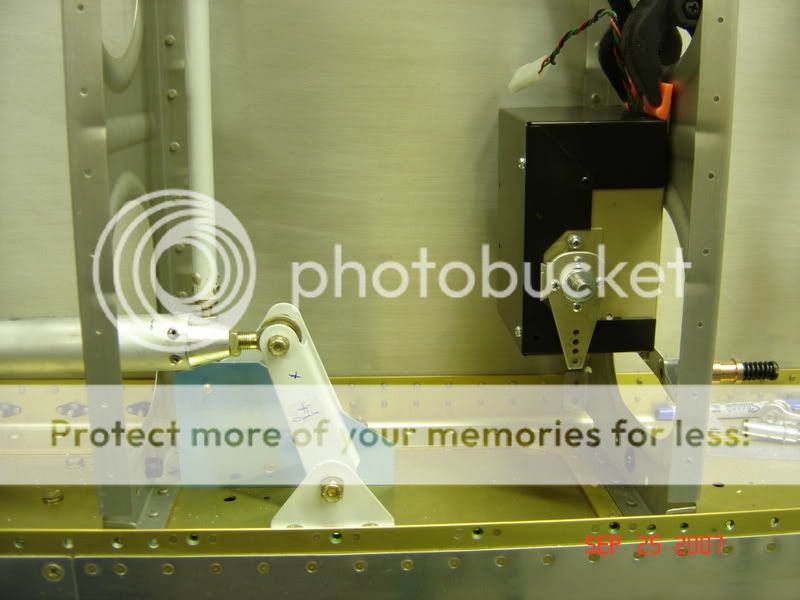

I purchased a used Navaid AP-1, now I'm at the servo mounting stage. I am planning on installing it in the bellcrank bay and am trying to plan ahead if I need to remove/replace. Here's a couple of pic showing my proposed location. My question is:

1. How much stop to stop movement is in the bellcrank?

2. Do you think the angles for the A/P pushrod will workout?

1. How much stop to stop movement is in the bellcrank?

2. Do you think the angles for the A/P pushrod will workout?