MIKE JG

Well Known Member

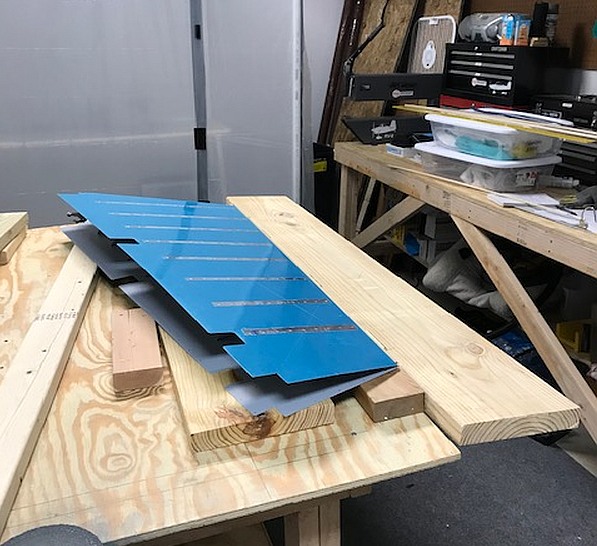

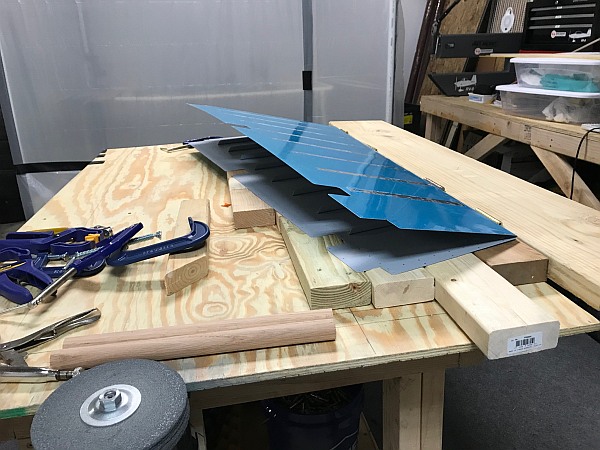

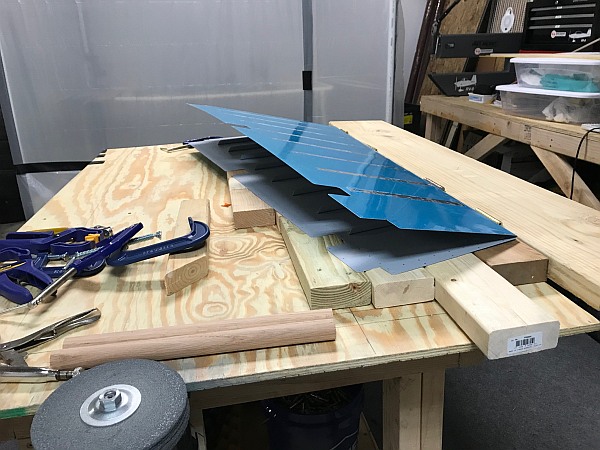

Looking for advice on how to get more bend out of my brake. The rudder is nearly there but I just can’t seem to get the final pinch to get it to lay in the proper position on the spar.

With the rudder in the brake and just the weight of the board, the rudder is perfect but as soon as the brake is taken off it springs back to about 2” of gap too much.

I started with 2 2x8” boards as Vans suggests. That didn’t seems to give me the results I needed so I switched to 2 2x4”’s made out of cedar, hinged on the 4” side so I was only using the small sides to do the squeezing. That didn’t seems to help so I tried this final setup witch is a 2x4” along with a 2x8”.

Using the brake I can push the rudder all the way down until the stiffeners are touching the opposite skin, so I can’t physically bend it any more than that. But it doesn’t remain there after the brake is taken away.

I got to thinking could the vinyl backing be causing it to not bend all the way??

I would appreciate any advice.

With the rudder in the brake and just the weight of the board, the rudder is perfect but as soon as the brake is taken off it springs back to about 2” of gap too much.

I started with 2 2x8” boards as Vans suggests. That didn’t seems to give me the results I needed so I switched to 2 2x4”’s made out of cedar, hinged on the 4” side so I was only using the small sides to do the squeezing. That didn’t seems to help so I tried this final setup witch is a 2x4” along with a 2x8”.

Using the brake I can push the rudder all the way down until the stiffeners are touching the opposite skin, so I can’t physically bend it any more than that. But it doesn’t remain there after the brake is taken away.

I got to thinking could the vinyl backing be causing it to not bend all the way??

I would appreciate any advice.

Last edited: