romanov

Well Known Member

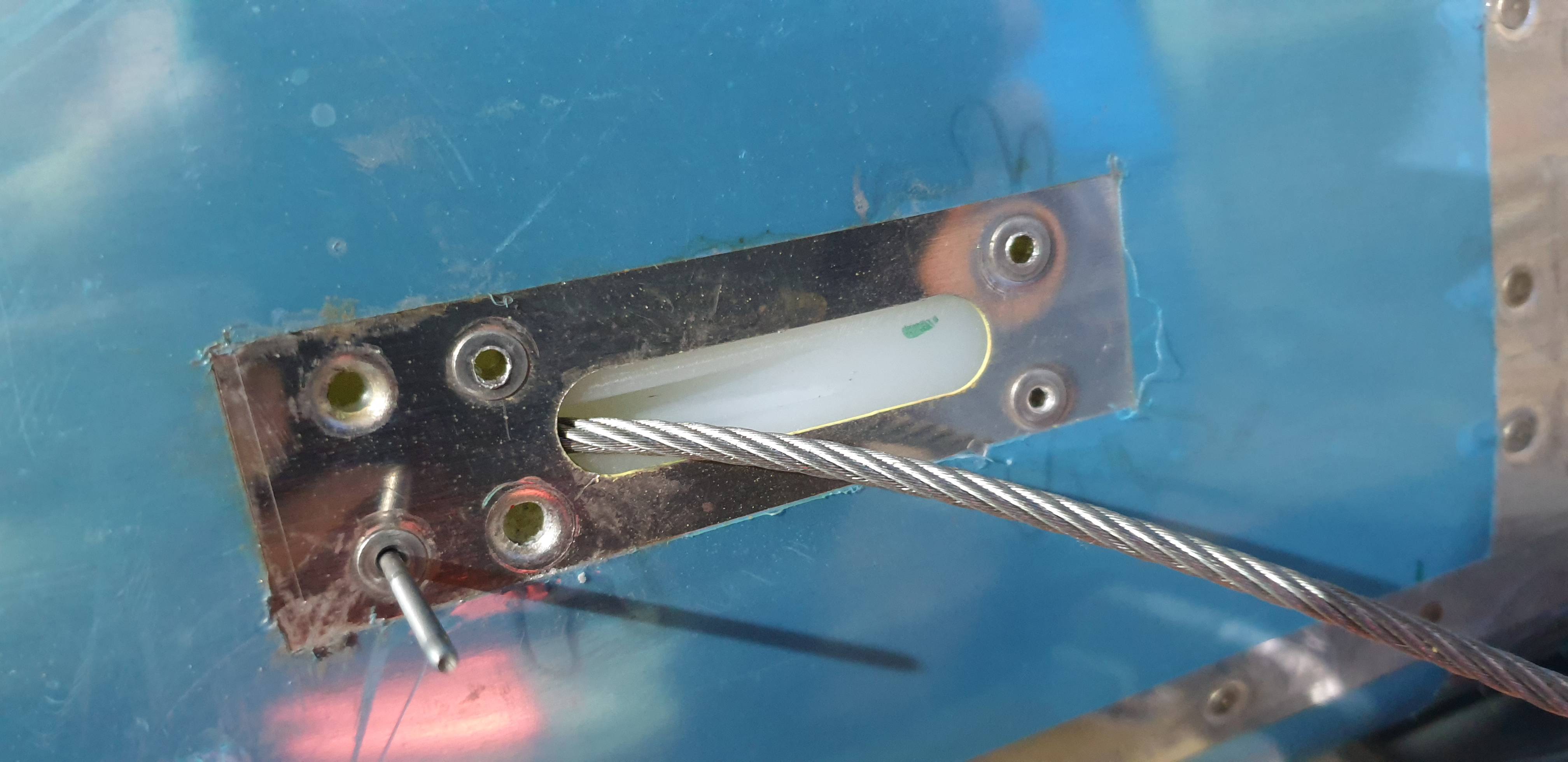

Guys,

I need some advise here:

The pop rivet turned to be absolutely hollow ,

the ball and the pin who supposed to hold it

from inside are completely torn out by the rivet

gun (seems like uncontrolable process with

this kind of rivets). We aware to the fact that

this os defenitely reduces the rivet strenght ,

but how bad is it? May this be acceptable at

this specific place ? Moreover , there in an

open hole in that place , how bad is that?

The location it happened is the plastic that leads

the cable for the rudder control. Here some pictures.

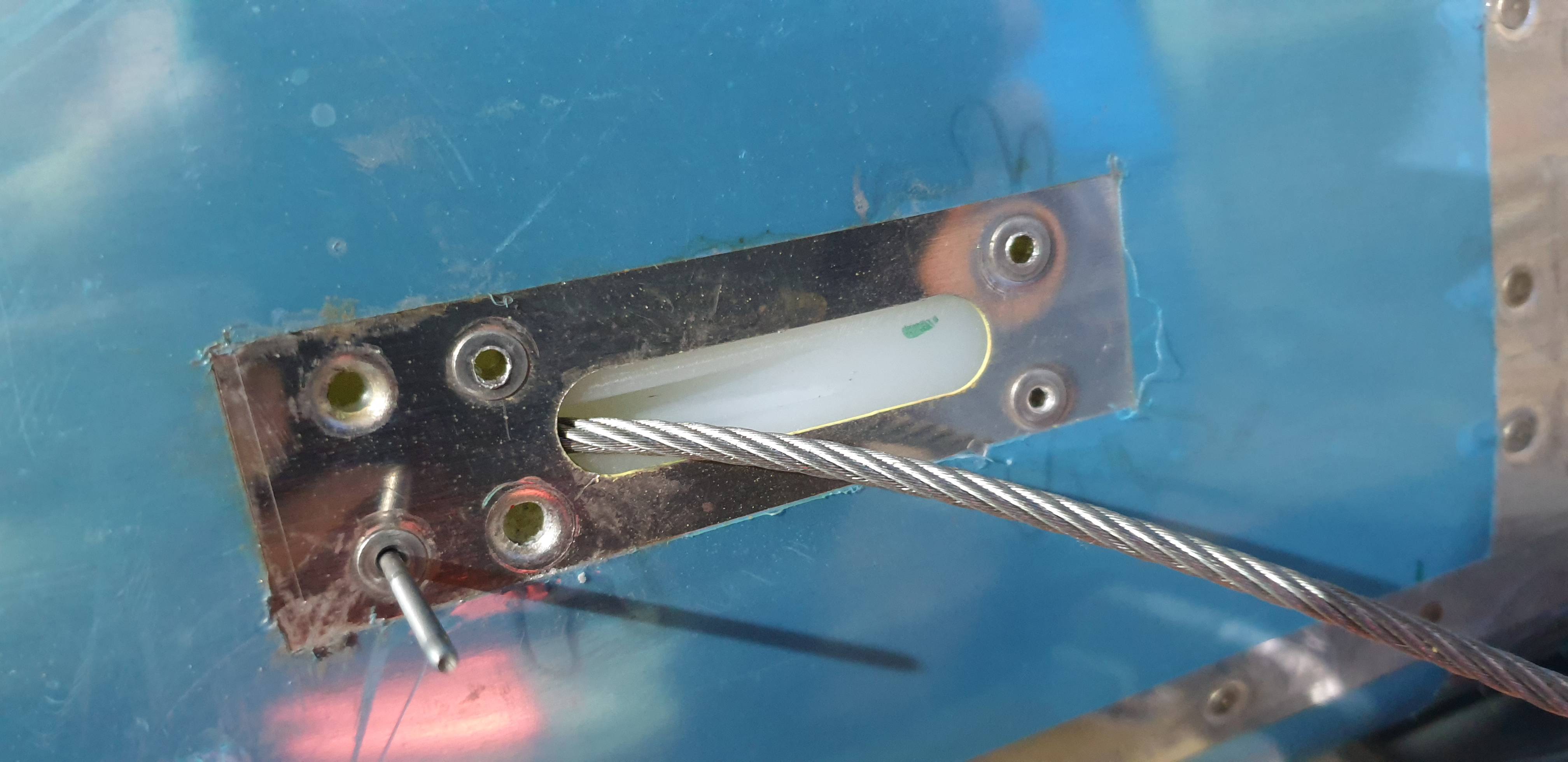

I need some advise here:

The pop rivet turned to be absolutely hollow ,

the ball and the pin who supposed to hold it

from inside are completely torn out by the rivet

gun (seems like uncontrolable process with

this kind of rivets). We aware to the fact that

this os defenitely reduces the rivet strenght ,

but how bad is it? May this be acceptable at

this specific place ? Moreover , there in an

open hole in that place , how bad is that?

The location it happened is the plastic that leads

the cable for the rudder control. Here some pictures.