Haven't quite figured out the quirks of nutplates yet i guess.

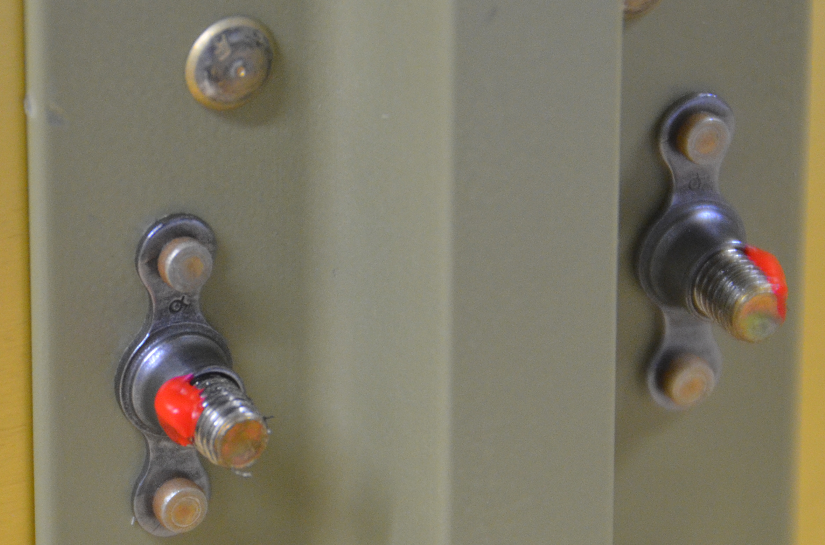

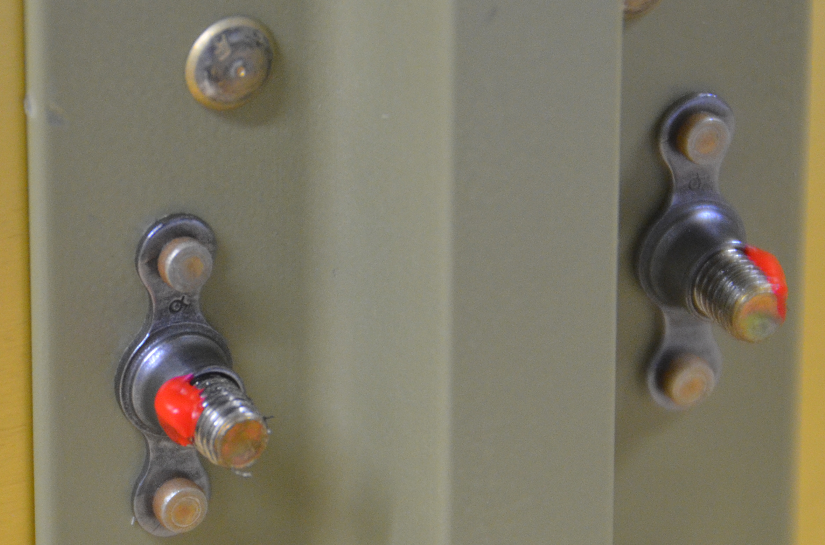

This is the tie-down AEX attached to the wing spar. The bolts here attach a powder coated bracket which I think is part of the aileron actuation bits and pieces.

Did I strip it? If so, do I need to drill out all the rivets to replace this nutplate? Or just change the bolt? I think this happened because my socket was too deep to help push those first few threads in. I have been using a dab of wax on the bolt.

Secondary question. I can't find torque values for bolts that go into nutplates, is there such a thing?

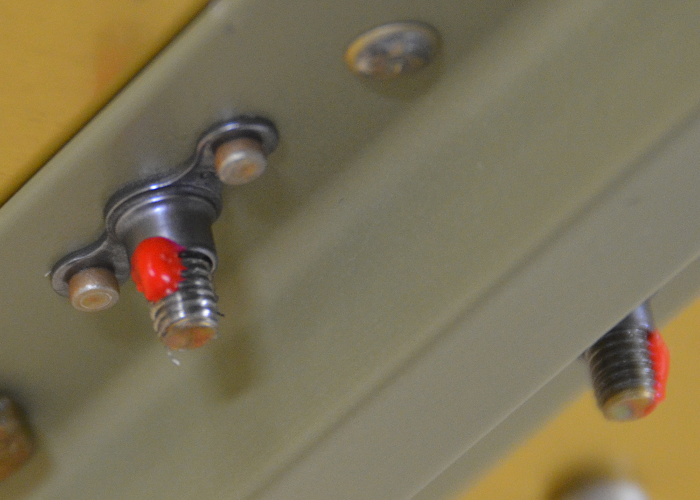

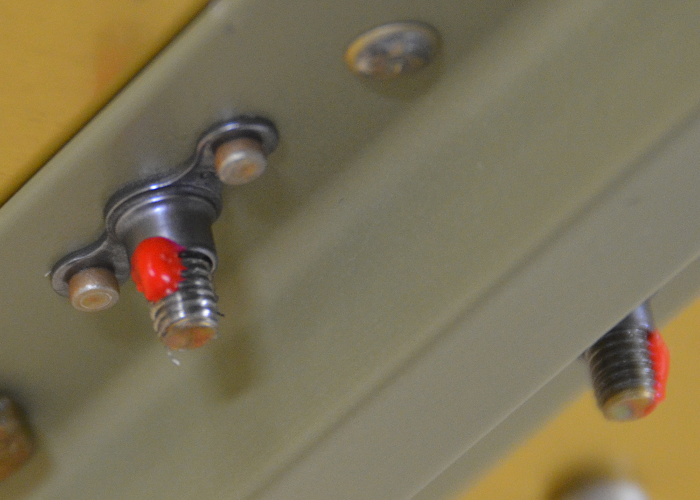

This is the tie-down AEX attached to the wing spar. The bolts here attach a powder coated bracket which I think is part of the aileron actuation bits and pieces.

Did I strip it? If so, do I need to drill out all the rivets to replace this nutplate? Or just change the bolt? I think this happened because my socket was too deep to help push those first few threads in. I have been using a dab of wax on the bolt.

Secondary question. I can't find torque values for bolts that go into nutplates, is there such a thing?