Rudder Rebuild

I apologize for thread drift as well and the long post. However, final paragraph is related to thread.

Polar,

I ordered the parts for the rudder rebuild just after I finished the first one. There were a few things I wasn't happy with. Looking back, I should have thought about it for a few days before ordering the new parts. Now as a more "experienced" builder I would probably just build on. However, since I had the parts I went ahead with the new one. I think the main reason I wanted to redo was because of a twist in the rudder. When placed on a flat surface, once side of the rudder was completely flat and the other was raised about .5" and would "rock" back and forth. The twist could have been due to several reasons, but I believe it was caused when I

incorrectly (prematurely) pulled the final side the adhesive tape off and the the trailing edge stuck together in the incorrect position (one hole off on the trailing edge). I pulled back loose and re-stuck, but think I may have pulled a twist in the process. For the second rudder, I followed the plans exactly regarding using the tape (section 5), and did not pull the final backing from the tape until all other riveting was complete. I think for the first one, I was concerned that if I waited until all other riveting was complete I would not be able to the get to the tape and peel it back. It turned to to be a non issue on the second one and the tape worked perfectly. I had every hole in the trailing edge clecoed and bonded with the tape on only one side. I then started slowly removing the protective backing from the final side slowly and removing/replacing clecos as I went. Worked great and the "new rudder" has only a very slight twist and overall build quality is much better (as it should be with a few more rivets under my belt

. I did have a slight setback during the new rudder though. I had just finished priming all the parts and had them inside the shop drying. I had the skins propped up against my work tables. I was cleaning up at the end of the day and happy that things were going pretty smoothly. However, I have a retractable electrical cord hanging from the ceiling and as I went to retract it, the plug end slipped out of my hand as it was retracting and the plug end of the cord slammed into the right side skin and put a solid golf ball size ding right in the middle of the skin. Had to reorder a new skin. Lesson learned..you can never let your guard down with most parts of this project or it WILL bite you

.

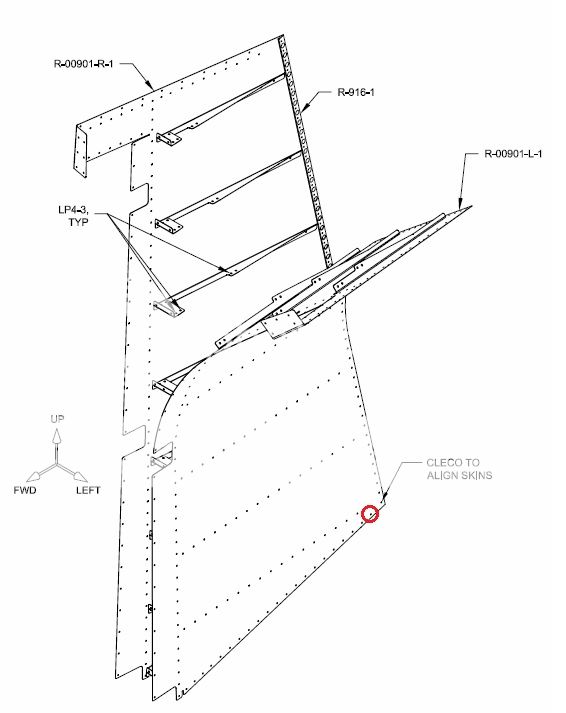

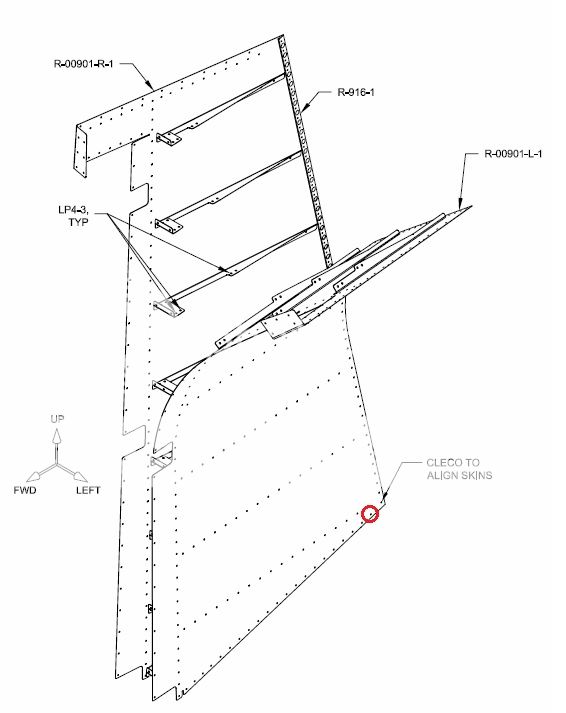

PS. I still need to update my blog and show the changes I made on the second rudder build. One thing (and related to this thread) that I did was to not rivet that lower rib together until I had those aft

9 (

not 8 as stated in the plans) rivets set. I was able to lift the skins easily and squeeze those rivets. The first rudder, as seen on my blog, I actually used solid rivets on that lower rib and was not able to "separate" this ribs to get to those aft rivets. Think I set with a very thin piece of metal. Followed plans and did not do that on the second rudder.