NorthernRV4

Well Known Member

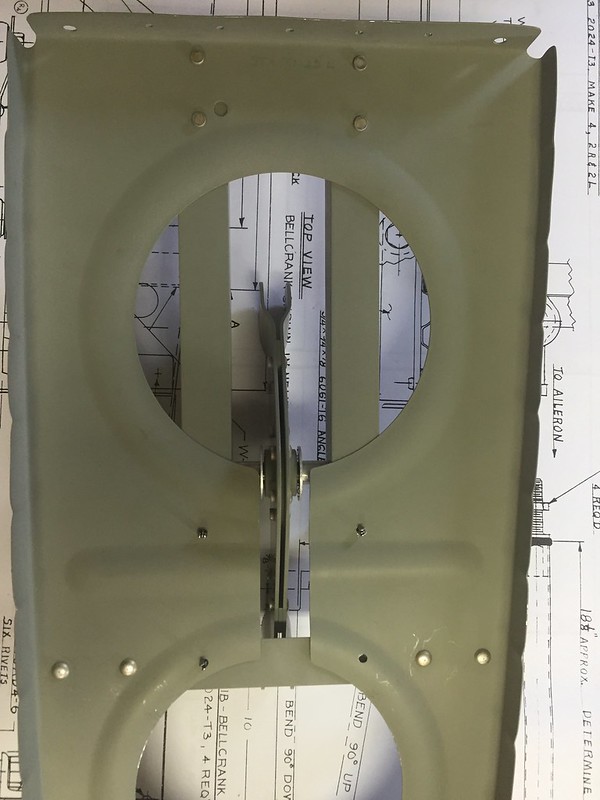

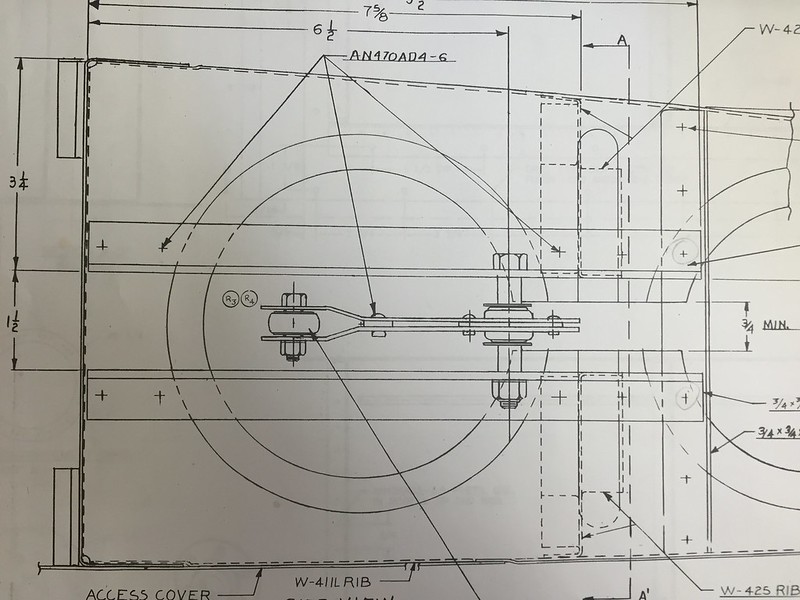

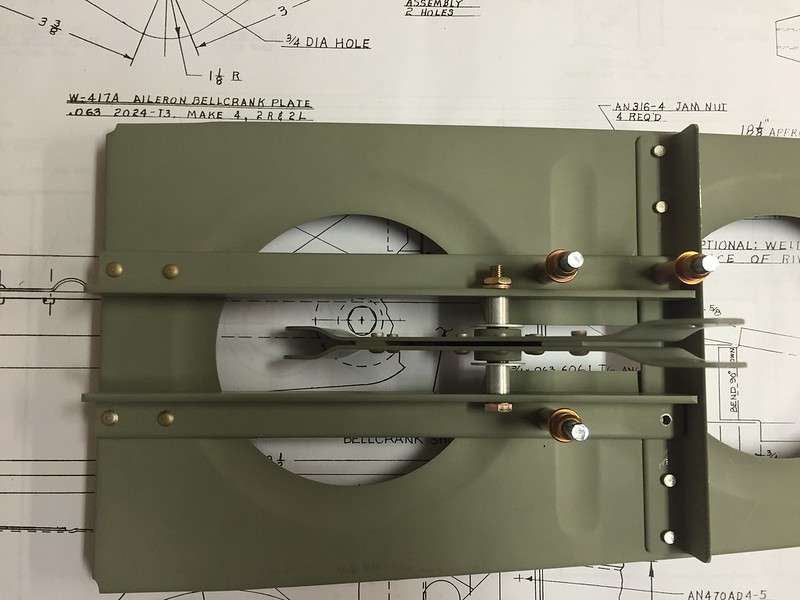

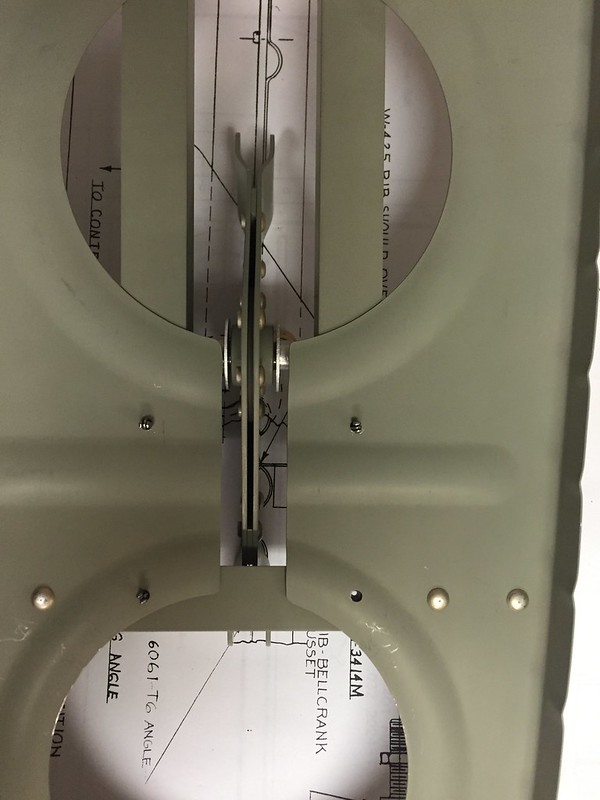

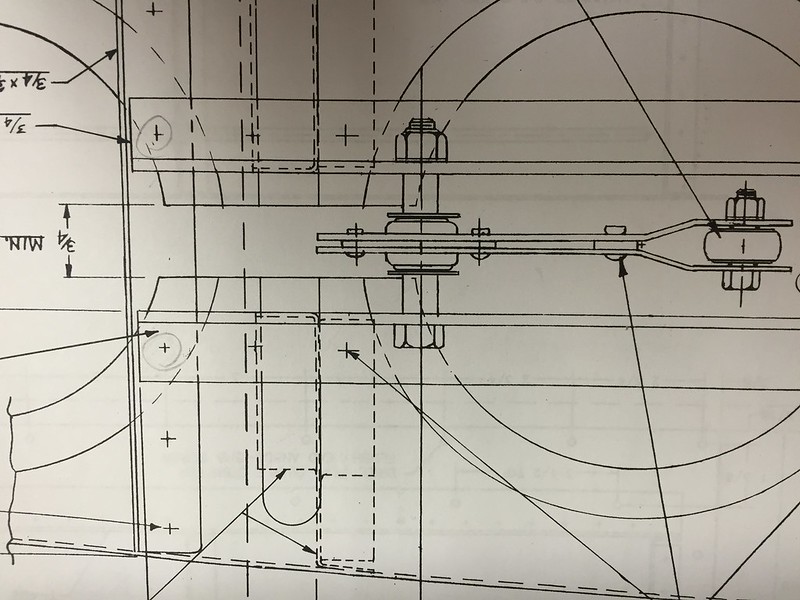

I'm wondering how other builders have dealt with this problem. Two of the rivets that attach the 3/4 angle are located right on the flanged ring around the second lightening hole. This is as per the plans but this leaves a gap between the angle and the rib web. Unfortunately I didn't notice this until I had started riveting.

Port aileron bellcrank rib by James Soutar, on Flickr

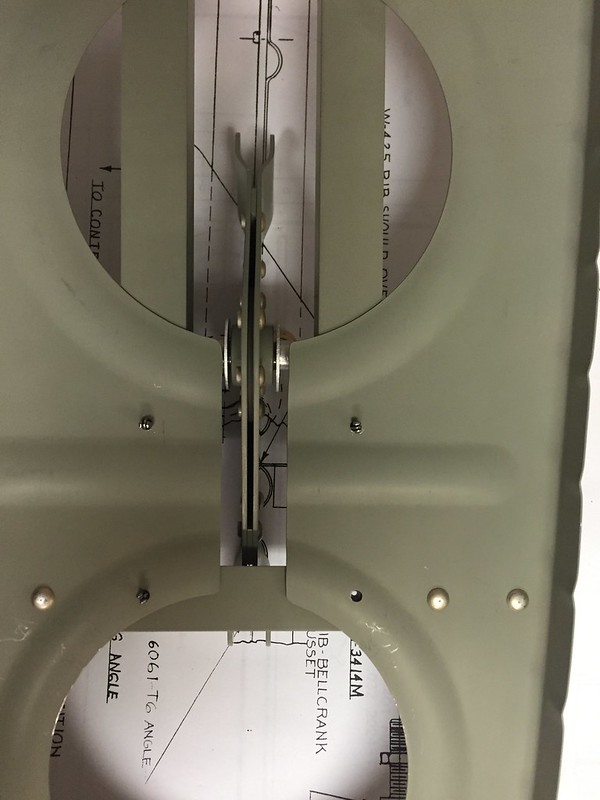

Port aileron bellcrank rib by James Soutar, on Flickr

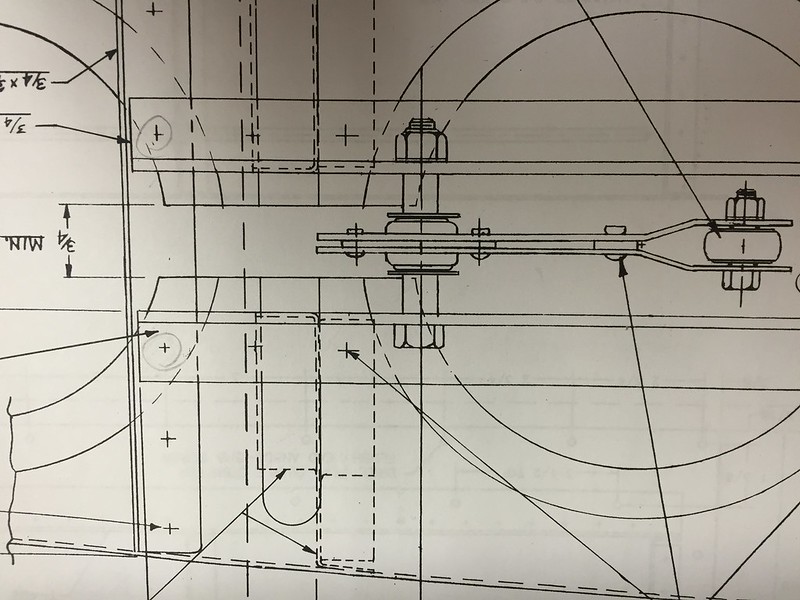

Port aileron bellcrank rib by James Soutar, on Flickr

Port aileron bellcrank rib by James Soutar, on Flickr

I'd like to flatten this area to the angle with a pair of flat sets and my squeezer by I don't think it will lay tightly to the angle. I'd rather not have to drill out the rivets to disassemble it. Any suggestions?

Port aileron bellcrank rib by James Soutar, on Flickr

Port aileron bellcrank rib by James Soutar, on Flickr Port aileron bellcrank rib by James Soutar, on Flickr

Port aileron bellcrank rib by James Soutar, on FlickrI'd like to flatten this area to the angle with a pair of flat sets and my squeezer by I don't think it will lay tightly to the angle. I'd rather not have to drill out the rivets to disassemble it. Any suggestions?