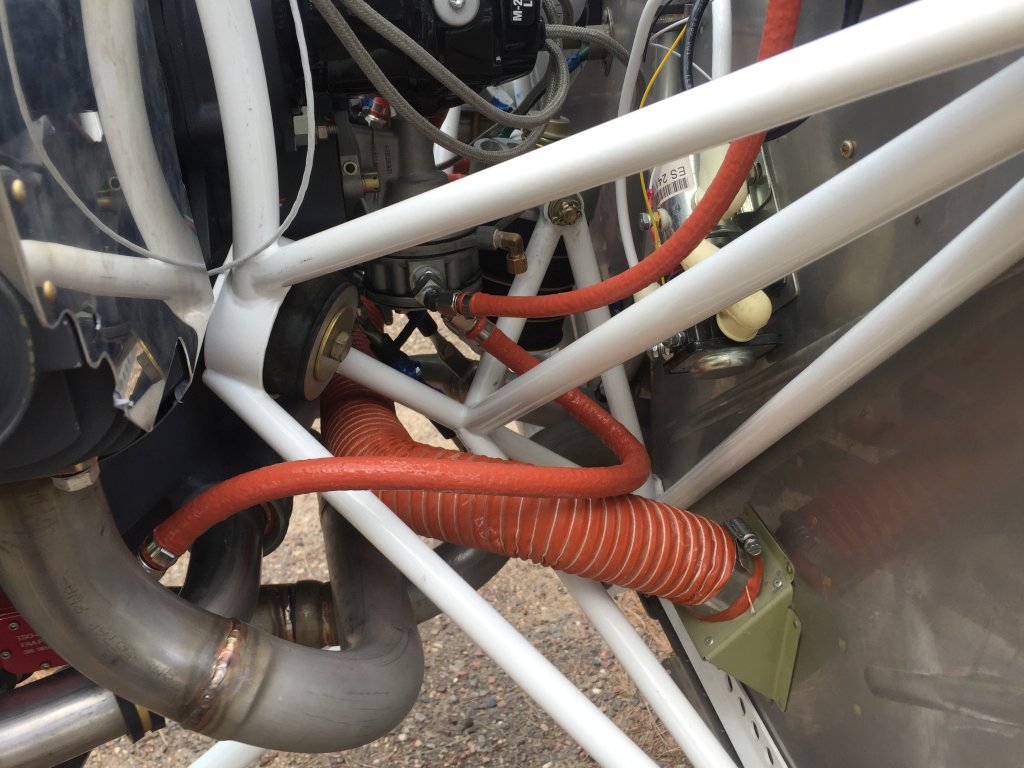

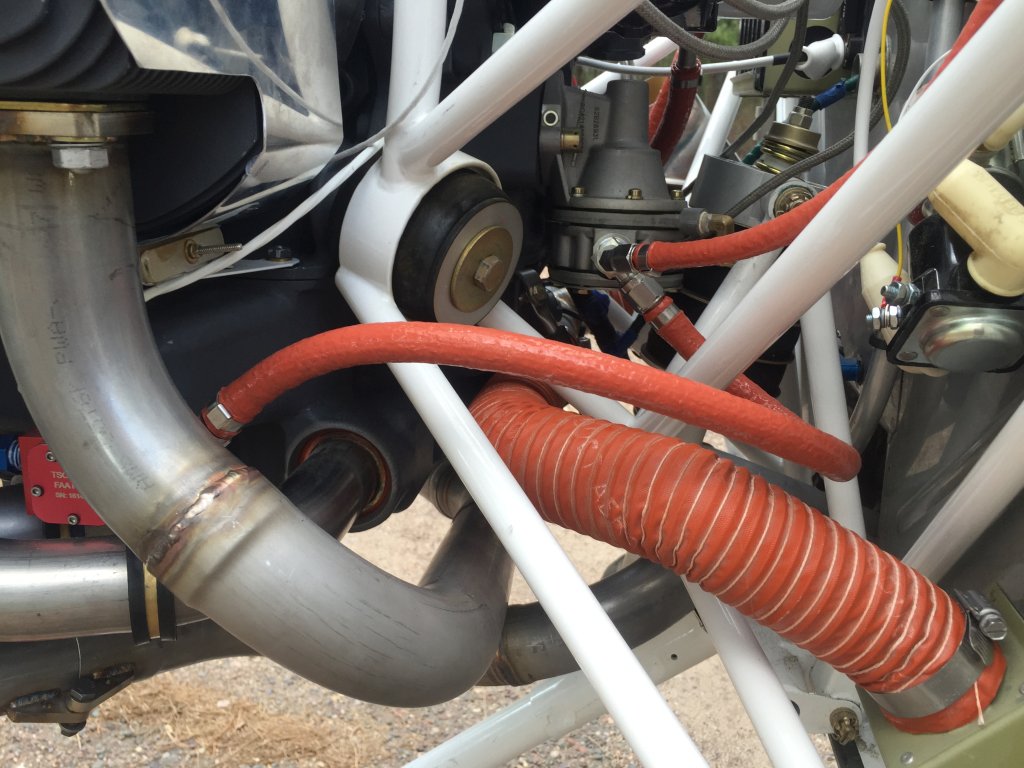

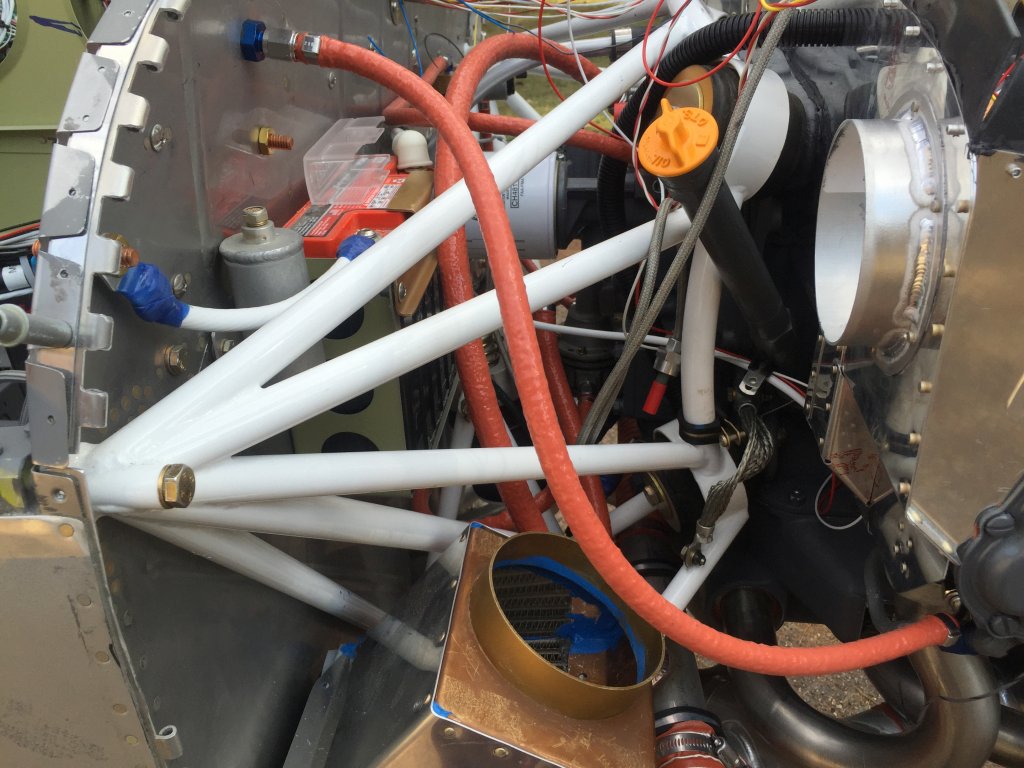

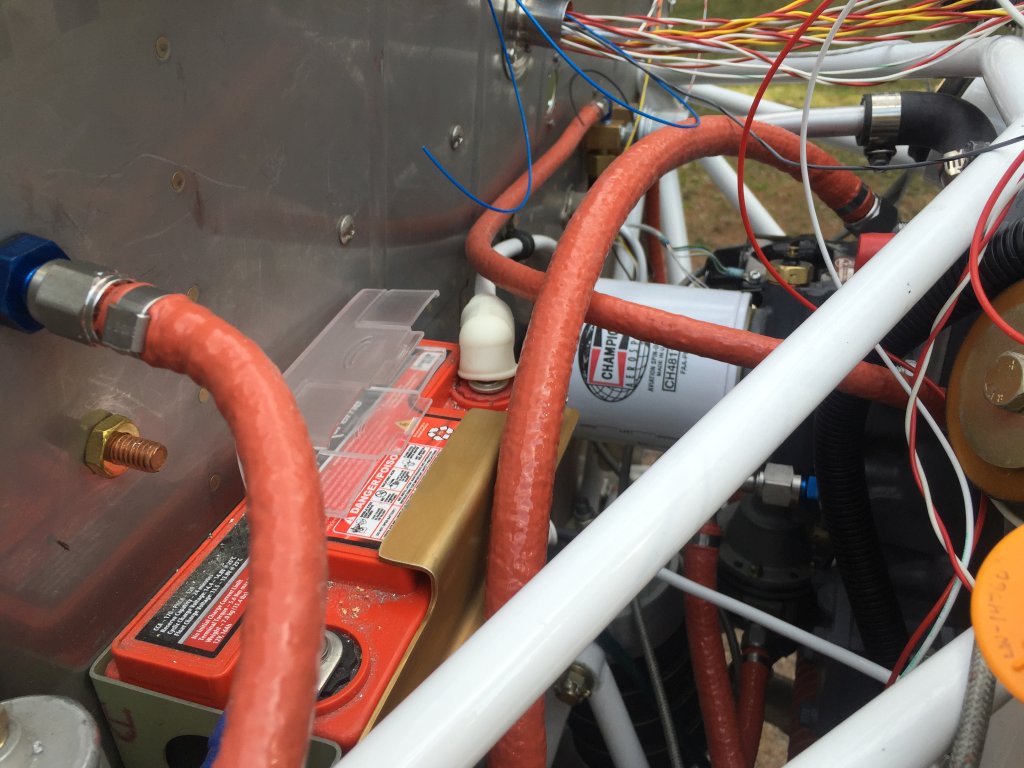

Wrapping up my Firewall Forward, one of the things I needed to get done was install all of the hoses. I had used Aircraft Specialty for all the brake and fuel hoses inside the fuselage, so I wanted the same known quality on the FWF. Additionally, I really like the idea of having firesleeve on EVERY hose, not just some of them. Steve at Aircraft Specialty feels the same way, so it was a good match to have him make my hoses.

For my hoses, there may be 2 differences from some builders' installations. One of them is that since I'm using a grand rapids EIS for an engine monitor, my sensors are not all the same. For my fuel pressure hose, I was able to go with a shorter hose than some people would need. For my manifold pressure sender, mine is mounted aft-firewall, so I used the same bulkhead style fitting as was used on my RV-10. In almost every aspect, this RV-14 is a copy of my RV-10 build.

As in my post about the Vetterman Exhaust, please note that when these pictures were taken, many extraneous things were not complete, so ignore any disconnected wires, loose nuts, or other things you may see. Just look at the hoses. It's a bit hard to get a good photo of the oil cooler hoses, once installed. Also, any green push-pull cables you will see are old ones that had melted or become stiff from my original RV-10 install. Today I have brand new black ones installed, so ignore any routing of the cables. They were there so that I could test for any interference with the hoses. Additionally, I feel it will be very important to heat shield the fuel hoses on the left side of the engine, and future photos I will take will show some good heat shielding.

For now though, know that if you choose to get top quality hoses, or have any special hose length needs due to your individual routing or construction, Aircraft Specialty and TS Flightlines can take care of you.

Here are the photos:

IMG]http://www.myrv14.com/postpics/hoses/IMG_8659.JPG[/IMG]

For my hoses, there may be 2 differences from some builders' installations. One of them is that since I'm using a grand rapids EIS for an engine monitor, my sensors are not all the same. For my fuel pressure hose, I was able to go with a shorter hose than some people would need. For my manifold pressure sender, mine is mounted aft-firewall, so I used the same bulkhead style fitting as was used on my RV-10. In almost every aspect, this RV-14 is a copy of my RV-10 build.

As in my post about the Vetterman Exhaust, please note that when these pictures were taken, many extraneous things were not complete, so ignore any disconnected wires, loose nuts, or other things you may see. Just look at the hoses. It's a bit hard to get a good photo of the oil cooler hoses, once installed. Also, any green push-pull cables you will see are old ones that had melted or become stiff from my original RV-10 install. Today I have brand new black ones installed, so ignore any routing of the cables. They were there so that I could test for any interference with the hoses. Additionally, I feel it will be very important to heat shield the fuel hoses on the left side of the engine, and future photos I will take will show some good heat shielding.

For now though, know that if you choose to get top quality hoses, or have any special hose length needs due to your individual routing or construction, Aircraft Specialty and TS Flightlines can take care of you.

Here are the photos:

IMG]http://www.myrv14.com/postpics/hoses/IMG_8659.JPG[/IMG]