After a six month hiatus, to change over from an Aerosance FADEC to a Precision Airmotive EMS, my aircraft is once again flying. The Aerosance FADEC (now a Continental Motors product) was becoming a liability. Periodically it would skip a beat, for no apparent reason, or give strange readings, that could not be explained. After years of frustration I decided it was time to make a change.

Strangely enough going back to the age of Magnetos and analog fuel injection did not interest me. I had considered the EFII system and was planning to go that way until I met Dennis Wyman of G&N Aircraft (www.gnaircraft.com) at Oshkosh last summer.

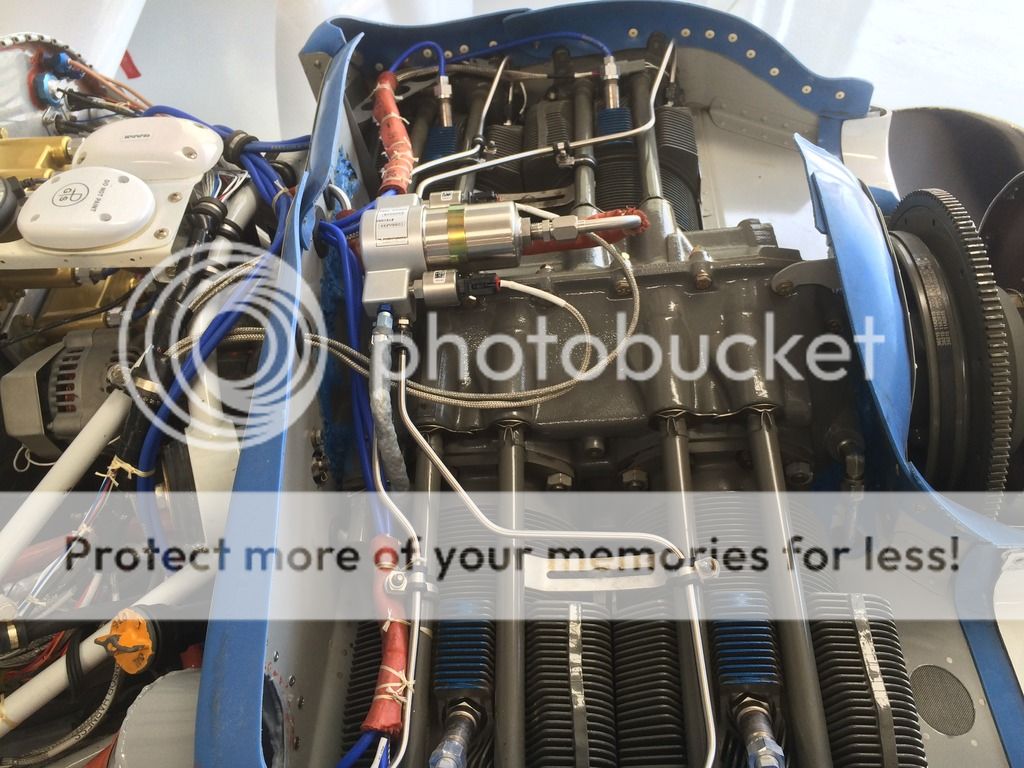

Dennis had an engine mockup with the Precision Airmotive, Eagle EMS System installed. Changing over to the the Eagle system would not require any new plumbing, there is no need for a "return to tank" system, and the fuel injectors would install right where the old ones went; no funky fuel rails spraying fuel into the side of the intake tubes. Unlike the old FADEC, The Eagle system is programable by You (meaning Me) the owner. No sending boxes back and forth for the EPROMS to be reprogramed. I can do it with my MacBook Laptop computer using a terminal program. Getting the Aerosance FADEC System to work on my aircraft eventually required removing the engine to the test cell in Mobile Alabama for "Tuning". Looking back at all the trouble I had getting the Arosance FADEC to work, by comparison, getting the Precision Airmotive Eagle system to work was a breeze.

The Installation was not without a few surprises. The biggest one was when I went to install the fuel injectors and they wouldn't screw in all the way. Come to find out, they work perfectly on the 180 horse (Parallel Valve) cylinders, but in order for them to work on the 200 horse (Angle Valve) cylinders, there is a bit of milling required on the cylinders around the fuel injector port. This was easily accomplished with a back-facing tool of the proper diameter, but took a bit of figuring, if you know what I mean. When other issues came up, they were expertly solved by Peter Nielson, Product Support Manager, and Dennis Anttila, Engineer and all over really smart guy. They were both a pleasure to work with.

I installed an O2 sensor, figuring it would help out with the initial mixture adjustments, but so far it was probably a waste of time and effort. The engine ran so well initially, with no adjustments at all on my part, that my first flight went perfectly with no adjustments whatsoever.

In future test flights I will be able to fine tune the mixture as necessary, or change the percentage ratio of fuel to each cylinder by changing the values in the Configuration and Volumetric Efficiency Tables, if necessary. While flying, I can lean the mixture using the Leaning Knob (a potentiometer) that allows the mixture to be leaned during cruse flight for better fuel economy.

While I am far from being completely confident in the Eagle System (talk to me in another year), I am optimistic that Precision Airmotive has a real gem on it's hands. I would not be surprised if they become the new standard for electronic fuel injection and ignition.

Dane Patterson

RV-8, N460DP

Strangely enough going back to the age of Magnetos and analog fuel injection did not interest me. I had considered the EFII system and was planning to go that way until I met Dennis Wyman of G&N Aircraft (www.gnaircraft.com) at Oshkosh last summer.

Dennis had an engine mockup with the Precision Airmotive, Eagle EMS System installed. Changing over to the the Eagle system would not require any new plumbing, there is no need for a "return to tank" system, and the fuel injectors would install right where the old ones went; no funky fuel rails spraying fuel into the side of the intake tubes. Unlike the old FADEC, The Eagle system is programable by You (meaning Me) the owner. No sending boxes back and forth for the EPROMS to be reprogramed. I can do it with my MacBook Laptop computer using a terminal program. Getting the Aerosance FADEC System to work on my aircraft eventually required removing the engine to the test cell in Mobile Alabama for "Tuning". Looking back at all the trouble I had getting the Arosance FADEC to work, by comparison, getting the Precision Airmotive Eagle system to work was a breeze.

The Installation was not without a few surprises. The biggest one was when I went to install the fuel injectors and they wouldn't screw in all the way. Come to find out, they work perfectly on the 180 horse (Parallel Valve) cylinders, but in order for them to work on the 200 horse (Angle Valve) cylinders, there is a bit of milling required on the cylinders around the fuel injector port. This was easily accomplished with a back-facing tool of the proper diameter, but took a bit of figuring, if you know what I mean. When other issues came up, they were expertly solved by Peter Nielson, Product Support Manager, and Dennis Anttila, Engineer and all over really smart guy. They were both a pleasure to work with.

I installed an O2 sensor, figuring it would help out with the initial mixture adjustments, but so far it was probably a waste of time and effort. The engine ran so well initially, with no adjustments at all on my part, that my first flight went perfectly with no adjustments whatsoever.

In future test flights I will be able to fine tune the mixture as necessary, or change the percentage ratio of fuel to each cylinder by changing the values in the Configuration and Volumetric Efficiency Tables, if necessary. While flying, I can lean the mixture using the Leaning Knob (a potentiometer) that allows the mixture to be leaned during cruse flight for better fuel economy.

While I am far from being completely confident in the Eagle System (talk to me in another year), I am optimistic that Precision Airmotive has a real gem on it's hands. I would not be surprised if they become the new standard for electronic fuel injection and ignition.

Dane Patterson

RV-8, N460DP

Last edited: