I recently completed all of the tasks on checklist for the annual.

For the oil change, there was only one tiny piece of metal in the filter, and the finger filter was entirely clean. All previous oil analysis has been normal, and I've only seen metal in the filter the first couple of oil changes.

I was ready to print out the logbook stickers, sign them, and go flying. But first I had to check compression and put spark plugs back in.

Numbers were 74 20 79 79. Dang.

I'd been having some morning sickness symptoms, but they hadn't happened since November, about 40 hours of flying. But suddenly they were back. EGT temps showed that #2 was dropping out. Sure enough, the #2 was hissing at the exhaust on the compression check.

OK, time to call the local (88R) mechanic and ream a valve guide.

I arranged to meet him and had everything ready to go. He pulls the spring

and has to hammer the valve through into the cylinder. It is really stuck. But we get it through and he uses a borescope to look at the valve guide. He doesn't like what he sees, lots of smearing, that's the way I would describe it.

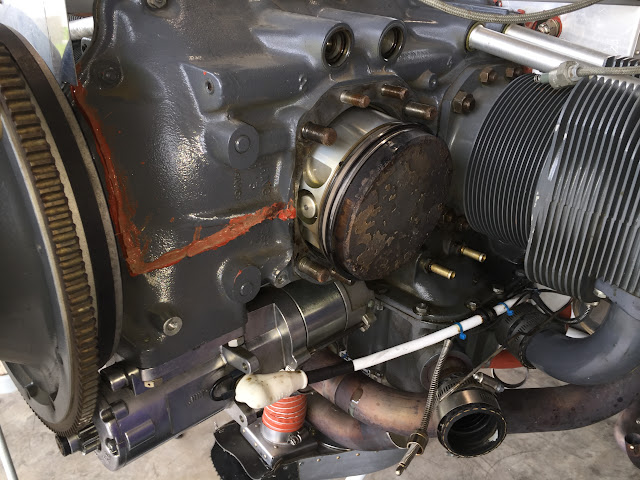

He says he doesn't think that reaming and returning to service is a great idea. So off comes #2.

We look inside:

The cylinder looks ok, but the valve is showing signs of cracking at the center. His assessment is that the yellow is indications of sodium leaking out.

With the cylinder out, we are able to see some of the cam lobes. Really bad news, significant spalling on #1 exhaust. Oddly, #2 looks fine.

So now a bit of morning sickness has turned into an engine teardown.

For the oil change, there was only one tiny piece of metal in the filter, and the finger filter was entirely clean. All previous oil analysis has been normal, and I've only seen metal in the filter the first couple of oil changes.

I was ready to print out the logbook stickers, sign them, and go flying. But first I had to check compression and put spark plugs back in.

Numbers were 74 20 79 79. Dang.

I'd been having some morning sickness symptoms, but they hadn't happened since November, about 40 hours of flying. But suddenly they were back. EGT temps showed that #2 was dropping out. Sure enough, the #2 was hissing at the exhaust on the compression check.

OK, time to call the local (88R) mechanic and ream a valve guide.

I arranged to meet him and had everything ready to go. He pulls the spring

and has to hammer the valve through into the cylinder. It is really stuck. But we get it through and he uses a borescope to look at the valve guide. He doesn't like what he sees, lots of smearing, that's the way I would describe it.

He says he doesn't think that reaming and returning to service is a great idea. So off comes #2.

We look inside:

The cylinder looks ok, but the valve is showing signs of cracking at the center. His assessment is that the yellow is indications of sodium leaking out.

With the cylinder out, we are able to see some of the cam lobes. Really bad news, significant spalling on #1 exhaust. Oddly, #2 looks fine.

So now a bit of morning sickness has turned into an engine teardown.

Last edited: