Arie

Well Known Member

Good day guys

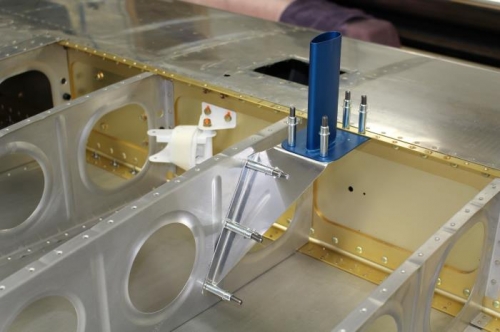

I have fitted my Safe Air1 Pitot mast with the Dynon pitot tube to the bottom of the left wing skin. Just outboard of the aileron bellcrank inspection panel. I followed the instructions from Safe Air for the installation and it came out looking great. I do however have a question regarding the rigidity of the mast where it is riveted to the skin at the back of the pitot mast. The front overlaps onto the spar which is great but at the back I can see some flexing of the skin if I apply a force to it . About 3/16 inch flexing. I think I am going to rivet a light weight stiffener to the skin between the two wing ribs ( like the stiffeners in the bottom of the fuel tank ) aft of the pitot mast mounting plate. This should make the aft side much more rigid. What do you guys think??.

[/URL][/IMG]

[/URL][/IMG]

[/URL][/IMG]

[/URL][/IMG]

[/URL][/IMG]

[/URL][/IMG]

[/URL][/IMG]

[/URL][/IMG]

I have fitted my Safe Air1 Pitot mast with the Dynon pitot tube to the bottom of the left wing skin. Just outboard of the aileron bellcrank inspection panel. I followed the instructions from Safe Air for the installation and it came out looking great. I do however have a question regarding the rigidity of the mast where it is riveted to the skin at the back of the pitot mast. The front overlaps onto the spar which is great but at the back I can see some flexing of the skin if I apply a force to it . About 3/16 inch flexing. I think I am going to rivet a light weight stiffener to the skin between the two wing ribs ( like the stiffeners in the bottom of the fuel tank ) aft of the pitot mast mounting plate. This should make the aft side much more rigid. What do you guys think??.