grayforge

Well Known Member

Arrggghhhh!

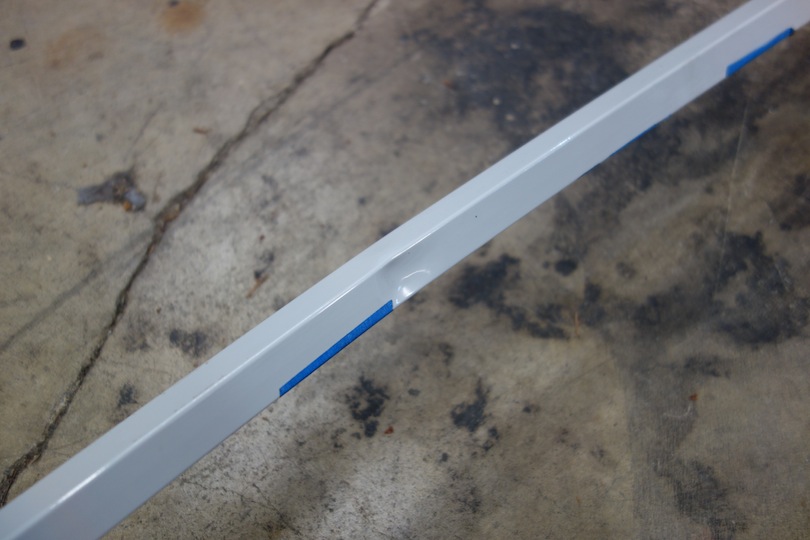

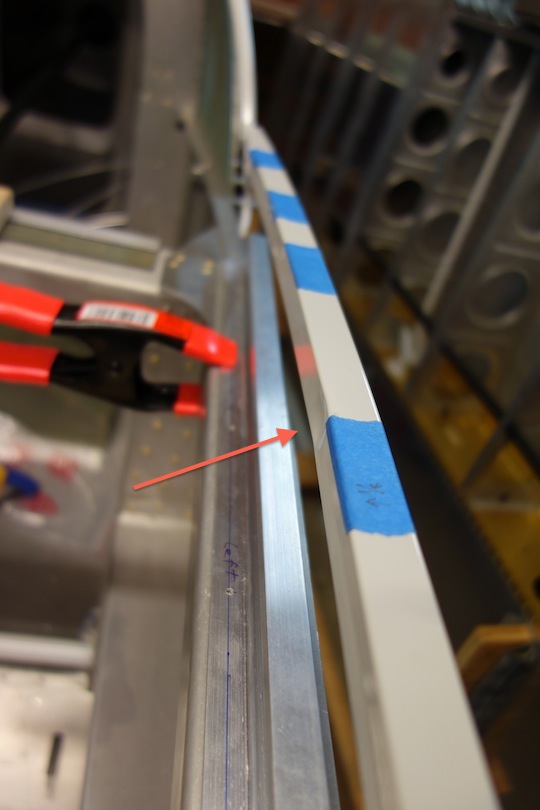

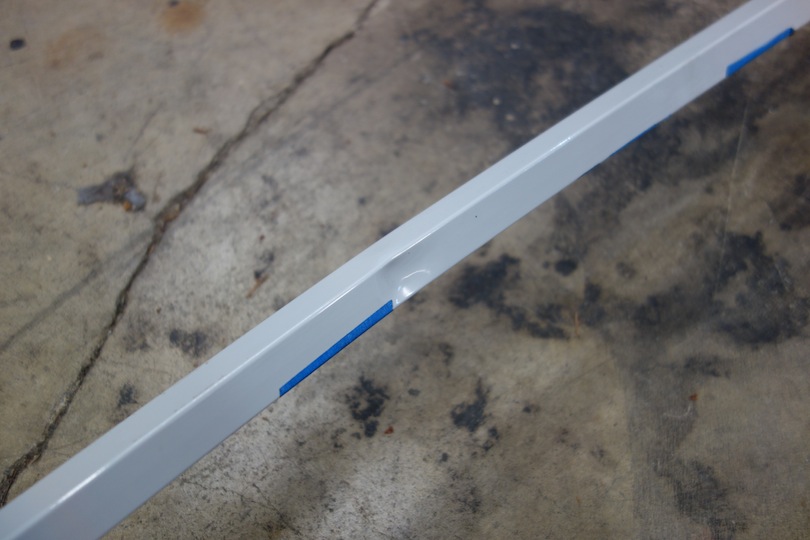

I was attempting to bend the slider canopy frame lower rail (the box section) to conform to the shape of my fuselage. I guess I shouldn't have clamped one end in a vise between a couple boards and pried on the other end... I ended up kinking the section. See the attached photos.

So what's my best bet? Should I swap the canopy frame out for a whole new one? If replacing the whole frame is overkill, what's the best fix for this?

I also sent an email to Russ McCutcheon, who fabricates these...

Thanks,

Russ

I was attempting to bend the slider canopy frame lower rail (the box section) to conform to the shape of my fuselage. I guess I shouldn't have clamped one end in a vise between a couple boards and pried on the other end... I ended up kinking the section. See the attached photos.

So what's my best bet? Should I swap the canopy frame out for a whole new one? If replacing the whole frame is overkill, what's the best fix for this?

I also sent an email to Russ McCutcheon, who fabricates these...

Thanks,

Russ