N546RV

Well Known Member

Cutting to the chase, I'm finally getting my hands dirty (literally) with fiberglass work. While working on my rudder bottom, and sanding the tail light pad flat, I went too far and needed to build it back up. So I laid up a few plies, then cleaned the area up and got ready to do my first bit of micro work. I mixed to what I thought was an appropriate peanut-butter consistency, but within 15 minutes of applying it I realized I definitely left it too wet, and it wasn't staying put:

Fortunately it didn't run too much, and tonight I got that mess sanded down and looking nice. Then I got ready to build up my rudder tip a bit to match its contour to the vertical stab tip. In the intervening time, I watched the EAA composite videos, and got a useful new metric for dry micro, namely mixing it until the stuff didn't "sag" at all.

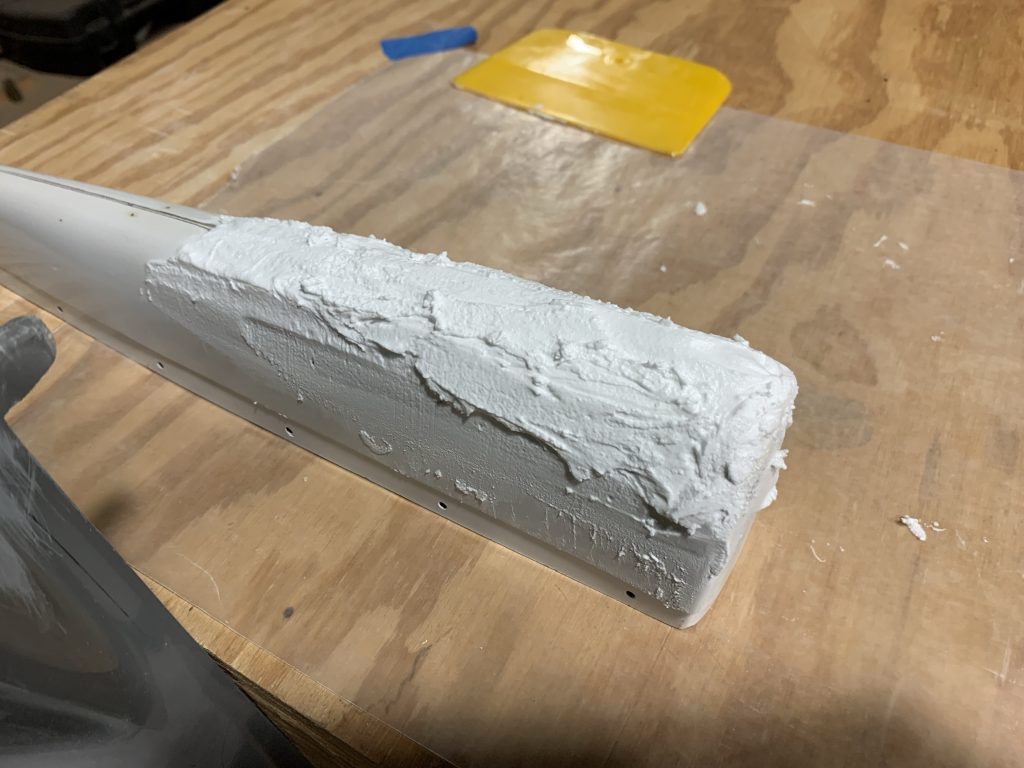

Tonight's mixture didn't run, which is good, but I found it extremely hard to work with. I never could seem to get it to lay down nicely, no matter how much careful work I did with a plastic spreader - half the time, it'd stick to the spreader and pull away from the work piece. Eventually I gave up on creating anything resembling a pleasing shape and just gooped on enough stuff that I figured I could sand this horror down to a semblance of the final shape:

What I'm wondering is whether I made this batch of micro too dry, and maybe that's why it was a real pain to spread? Or is this just me needing some better technique for spreading the stuff? Any other thoughts or advice to offer?

Fortunately it didn't run too much, and tonight I got that mess sanded down and looking nice. Then I got ready to build up my rudder tip a bit to match its contour to the vertical stab tip. In the intervening time, I watched the EAA composite videos, and got a useful new metric for dry micro, namely mixing it until the stuff didn't "sag" at all.

Tonight's mixture didn't run, which is good, but I found it extremely hard to work with. I never could seem to get it to lay down nicely, no matter how much careful work I did with a plastic spreader - half the time, it'd stick to the spreader and pull away from the work piece. Eventually I gave up on creating anything resembling a pleasing shape and just gooped on enough stuff that I figured I could sand this horror down to a semblance of the final shape:

What I'm wondering is whether I made this batch of micro too dry, and maybe that's why it was a real pain to spread? Or is this just me needing some better technique for spreading the stuff? Any other thoughts or advice to offer?