All,

What Vbg speeds have you all validated through flight tests? There have been a number of engine out, followed by stall spin accidents this past year.

I'm wondering if any of those were complicated by using the wrong speed for best glide, and then running out of energy short of the intended landing spot.

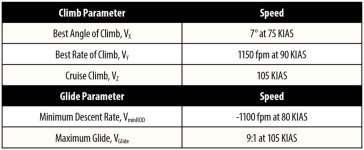

There seems to be some debate about min sink speeds and maximum glide range speeds (Vbg) on this forum. Regardless of small variances due to build, shouldn't Vbg generally be close to Vy for any given airplanes. This is L/D max at climb power.

I'm asking because I've seen some POHs show Vbg for RV7s in the 80 kt range, including the checklist I inherited when I bought my RV7 from a another owner, who was not the original builder. When I tested it, however, I found 95 kts to be the number for Vbg. I sold the RV7 last year, and now own an 8A, which I purchased from the builder. I did my own tests on it, and my Vbg test results show Vbg to be 100-104 kts, depending on wgt.

A simple way to compare whether Vbg is closer to 80k or 100k is to try this in 2 successive the landing patterns to low approaches in your constant speed prop airplane:

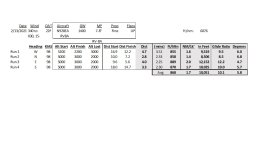

Run 1) trim for 80 kts, flaps up. Plan a normal pattern at a safe altitude. Set MP to min per your comfort level, prop at low rpm to simulate an engine out condition. When you roll out on final, ascertain your likely touchdown point. At a safe low approach altitude, set prop to max RPM and MP to max, and execute a normal go-around. Be ready to retrim as needed for the climb out, as always.

Run 2) do everything the same way, trimming for 80 kts. However, after you roll out on final and assess your likely touchdown point at 80 kts, lower the nose and accelerate/trim to 100kts. See how your touchdown point changes. Again, at a safe altitude, execute a normal go-around.

I found that in Run 2), after accelerating to 100k, my likely touchdown point moved substantially further away the runway. Clearly, my Vbg is much closer to 100 than to 80. These results prompted me to go out and do the tests recommended by Jaros, and get a more precise measurement of Vbg.

I'm very interested in results others may find.

Safe flying!

What Vbg speeds have you all validated through flight tests? There have been a number of engine out, followed by stall spin accidents this past year.

I'm wondering if any of those were complicated by using the wrong speed for best glide, and then running out of energy short of the intended landing spot.

There seems to be some debate about min sink speeds and maximum glide range speeds (Vbg) on this forum. Regardless of small variances due to build, shouldn't Vbg generally be close to Vy for any given airplanes. This is L/D max at climb power.

I'm asking because I've seen some POHs show Vbg for RV7s in the 80 kt range, including the checklist I inherited when I bought my RV7 from a another owner, who was not the original builder. When I tested it, however, I found 95 kts to be the number for Vbg. I sold the RV7 last year, and now own an 8A, which I purchased from the builder. I did my own tests on it, and my Vbg test results show Vbg to be 100-104 kts, depending on wgt.

A simple way to compare whether Vbg is closer to 80k or 100k is to try this in 2 successive the landing patterns to low approaches in your constant speed prop airplane:

Run 1) trim for 80 kts, flaps up. Plan a normal pattern at a safe altitude. Set MP to min per your comfort level, prop at low rpm to simulate an engine out condition. When you roll out on final, ascertain your likely touchdown point. At a safe low approach altitude, set prop to max RPM and MP to max, and execute a normal go-around. Be ready to retrim as needed for the climb out, as always.

Run 2) do everything the same way, trimming for 80 kts. However, after you roll out on final and assess your likely touchdown point at 80 kts, lower the nose and accelerate/trim to 100kts. See how your touchdown point changes. Again, at a safe altitude, execute a normal go-around.

I found that in Run 2), after accelerating to 100k, my likely touchdown point moved substantially further away the runway. Clearly, my Vbg is much closer to 100 than to 80. These results prompted me to go out and do the tests recommended by Jaros, and get a more precise measurement of Vbg.

I'm very interested in results others may find.

Safe flying!