Bob Martin

Well Known Member

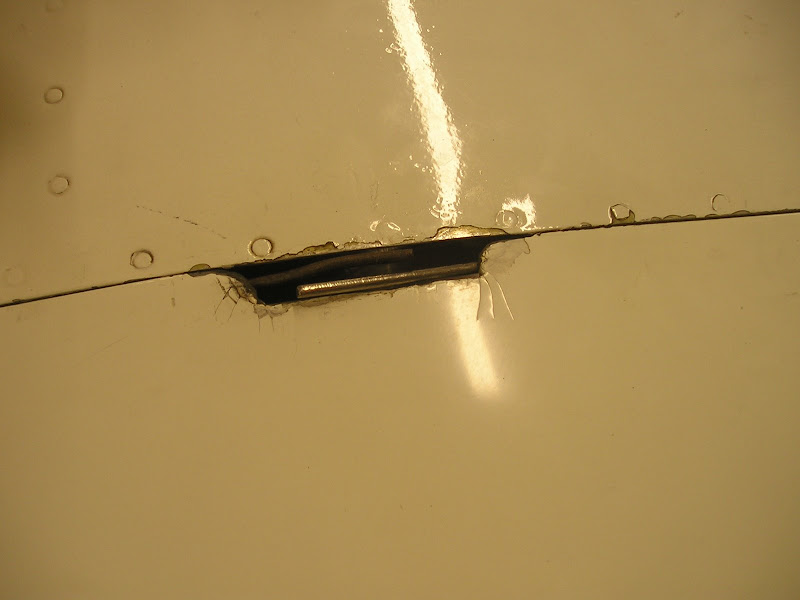

Top cowling hinge pin termination

Ok, so not so many replys so far, thought I'd help with a picture.

As they say, a pictures is worth a 1000 words.

This pictures, if I embedded it correctly....thanks Larry!

is of my top cowling hinge pin termination location, as you can see, it isn't very pretty after 650 hours, and many removal and replacements.

Again, I'm pretty sure I've seen where some builders have instaled some plates or covers to make this area look better. I'm looking for suggestions of ideas that have worked or pictures of what you have done or seen.

Thanks in advance for any information.

Ok, so not so many replys so far, thought I'd help with a picture.

As they say, a pictures is worth a 1000 words.

This pictures, if I embedded it correctly....thanks Larry!

is of my top cowling hinge pin termination location, as you can see, it isn't very pretty after 650 hours, and many removal and replacements.

Again, I'm pretty sure I've seen where some builders have instaled some plates or covers to make this area look better. I'm looking for suggestions of ideas that have worked or pictures of what you have done or seen.

Thanks in advance for any information.