This hinge shim mod is a welcome upgrade. Re-installing the stabilator using washer spacers, which always get knocked off, is very frustrating. The service letter illustrations and instructions pertain primarily to the iS with a note that the RV-12 hardware is different. It is quite different, in fact. On th iS stab the outboard hinge brackets can't be easily removed and replaced. On the RV-12 stabilator the complete hinge bracket assemblies can be removed and the shims installed on the bench.

I don't have the parts yet, just thinking it through.

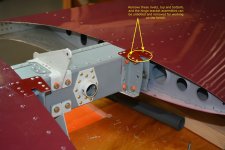

My stabilator so the picture pertains to the classic RV-12 not the RV-12iS:

I don't have the parts yet, just thinking it through.

My stabilator so the picture pertains to the classic RV-12 not the RV-12iS: