HeliCooper

Well Known Member

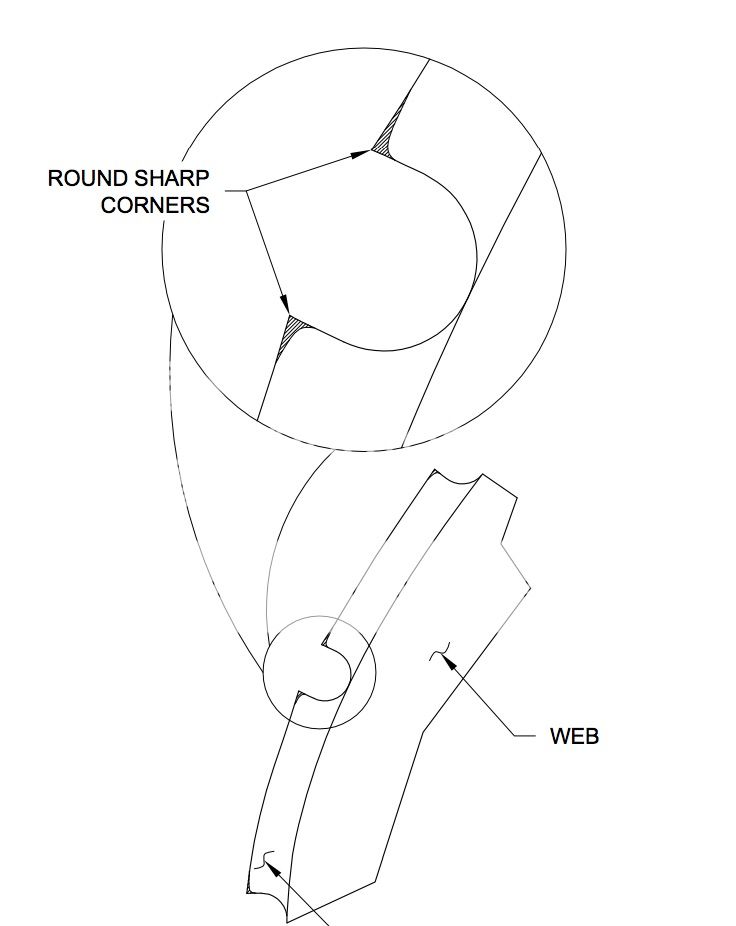

I hate to be a new guy here but I am wondering exactly what they want faceted on page 10-06. The diagram they show appears to be the edges that are already rounded. I guess I don't exactly understand what they want faceted.